13

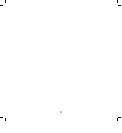

Switch on the jigsaw and allow

the blade to reach maximum

speed.

Slowly guide the jigsaw forward,

building up speed as you go,

with one hand on the handle

and the other on the scrolling

knob, keeping the shoe plate flat

against the workpiece (fig b).

Do not force the jigsaw. Use only enough pressure to keep

the blade cutting. Do not force the cutting, allow the blade

and the saw to do the work.

Pocket & curve cutting

In order to start a cut from the

centre of the workpiece, you can

either drill a hole and insert the

blade into the hole then start

cutting, or plunge cut (fig c).

When using the hole method,

use a 10mm or larger drill to

ensure that there is sufficient

clearance for the blade (fig d).

To plunge cut, proceed as

follows.

Tilt the tool on the front edge

of the shoe plate (18) with the

point of the blade just above the

workpiece (fig e).

Switch on, wait for the blade to

reach maximum speed, hold the

front edge of the shoe plate (18)

securely against the workpiece

and slowly lower the rear of the

saw so that the blade penetrates

the workpiece.

When the shoe plate is flush

with the surface of the workpiece,

proceed with cutting in the normal manner.

When cutting tight curves, reduce the speed of the saw.

WARNING. Do not move the saw forward

along its cut until the blade has completely entered the

material and the shoe comes to rest on its surface.

Metal cutting

NOTES.

• When cutting metal ALWAYS clamp down the

metal workpiece.

• Be extremely careful to move the saw very slowly as

you cut. Use slower speeds (Position 1 on the speed

controller).

DO NOT twist, bend or force the blade.

• When cutting metals, a suitable cooling/cutting oil must

be used. Squirt the lubricant onto the blade or workpiece

at regular intervals during cutting in order to reduce wear

on the blade.

• If the saw jumps or bounces as you cut, change to a

blade with finer teeth.

• If the blade begins to clog when cutting soft metal,

change to a blade with coarser teeth.

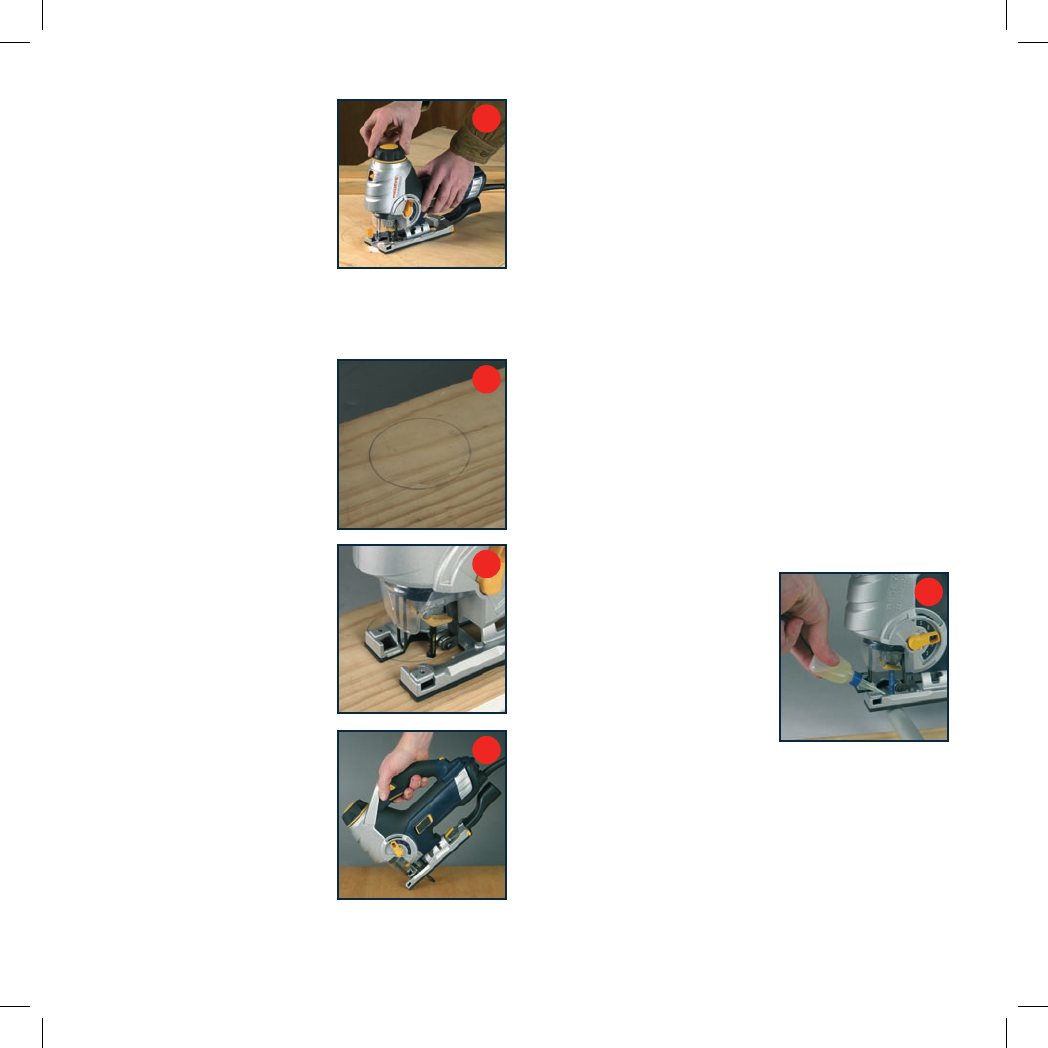

• For easier cutting, lubricate

the blade with a stick of cutting

wax (if available) or cutting oil

when cutting steel (fig f).

• Thin metal should be

sandwiched between two

pieces of wood or tightly

clamped on a single piece

of wood (wood on top of the

metal). Draw the cut lines or design on the top

piece of wood.

• When cutting aluminum extrusion or angle iron, clamp

the work in a bench vice and saw close to the vice jaws.

• When sawing tubing with a diameter larger than the

blade is deep, cut through the wall of the tubing and then

insert the blade into the cut, rotating the tube as you saw.

e

f

c

d

b

e