0-nd a specific type

of

solvent, check the com-

atability

of

the solvent to.be used

for

thinning

he material by dropping

a

single drop

of

the

materi-

1

into a

small

container

of

".he solvent.

If

the

laterial drop clouds

or

disperses readily, the

sol-

.ent

is

compatible.

If

drop tends to string

or

'orm

a ball, the solvent

is

not compatible

and

.efinitely should not be used.

Nm:

If

manufacturer

of

material does not re-

AGITATION

OF

MATERIAL

lccomolished prior to

~umpinn

material to soray

E.

Agitation can best be obtained

as

follows:

Thorouah agitation of material should be

;ator

air

fitting

and agitator

WFU

be

energized.

lefer to Fig.

1.

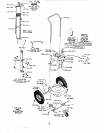

1.

Snap

air

line coupler

202437

onto agi-

2.

Wn

agitator

air

valve

x)5-528,

t'm

or

nore turns to the left to

start

agitator

air

notor. Refer to Fig.

1.

Speed

of

agitation

nay be adjusted to

suit

the particular viscosity

speed may cause vibration and foaming

of

material.

,P

material used.

N.WTE:

Excessive agitation

he moderate agitation speeds

at

all

times.

This

permits pump circulate the material under

light

load.

3.

Open

manifold dump valve and

start

pump.

1.

Lift

hinped inspection plate and examine

progress

of

agitaiion through hie

in

cover.

It

is

extremely important that

all

solids are

DUt

in

suspension and held there dbring the entire spray

operation.

5.

Allow

agitator to continua operation

hile unit

is

supplying

material

to spray

gun.

SUPPLYING MATERtAL

TO

GUN

.fter material has been circulated sufficiently

nd before attempting to spray. When closed,

nob

of

dump valve

is

in

a

horizontal position.

1.

Stop pump and close manifold dump valve

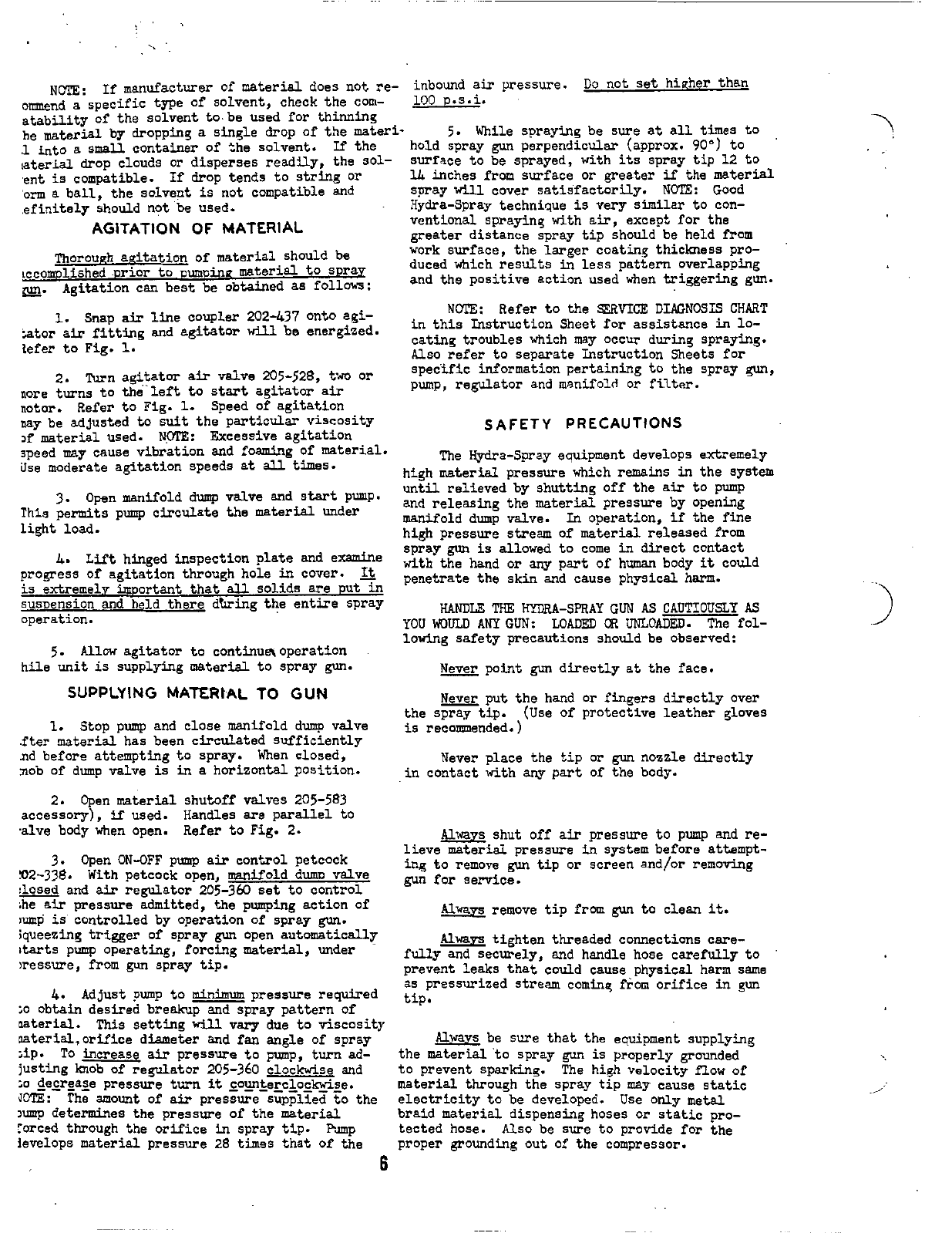

2.

@en

material

shutoff valves

205-583

accessory),

if

used. Handles are parallel to

.alve body when open. Refer

to

Fig.

2.

3.

open ON-OFF

pump

air

control petcock

92-38.

With petcock open, mifold dumu valve

:losed

-

and

air

regulator

205-360

set to control

.he

air

pressure admitted, the pumping action of

mmp

is

controlled by operation

of

spray

gun.

iqueezing trigger

of

spray

gun

open automatically

itarts

pump operating, forcing material, under

ressure, from

gun

spray tip.

;o

obtain desired breakup and spray pattern

of

naterial.

This

setting

will

vary due to viscosity

naterial,orFfice diameter and fan angle

of

spray

;ip.

TO

increase air pressure to pump, turn

ad-

:o

iecrgaze pressure turn

it

gagniegc&o+&e.

justing knob

of

regulator

205-360

clocMse and

1ump

determines

the

pressure

of

the material

JOTE:

The amount

of

air

pressure supplied to the

'orced through the orifice

in

spray tip. Pmp

levelops material pressure

28

times that

of

the

4.

Adjust pump to pressure required

6

inbound air pressure.

Do

not

set

hieher than

100

0.s.i.

hold spray

gun

perpendicular (approx.

90")

to

5.

While spraying be sure at

all

times to

surface to be sprayed, with

its

spray tip

12

to

U

inches

from

surface

or

greater

if

the

material

spray

will

cover satisfactorilg. NOTE: Good

Hydra-Spray technique

is

very

similar

to

con-

ventional spraying with air, except

for

the

greater distance spray tip should be held

from

work surface, the

larger

coatinq thichss pro-

duced which results

in

less pattern overlapping

and the positive action used when triggering gun.

in this Instruction Sheet

for

assistance

in

10-

NOTE:

Refer to the

SERVTCE

DIAGNOSIS

CHART

cating troubles which may occur during spraying.

Also

refer to separate Instruction Sheets

for

pump, regulator and manifold

or

filter.

spec'ific information pertaining to the spray

gun,

SAFETY PRECAUTIONS

high

material

pressure which

remains

in

the system

until relieved by shutting off the

air

to pump

manifold dump valve.

In

operation,

if

the fine

and releasing the material pressure by opening

high pressure stream

of

material released from

spray

gun

is

allowed to come

in

direct contact

with the hand

or

any

part

of

human body

it

could

penetrate the

skin

and cause physical harm.

The Hydra-Spray equipment develops extremely

HANDLE

THE

HYDFA-SPRAY

GUN

AS

CAUTIOUSLY

AS

YOU

WULU

ANYGUN:

LO-

OR

UNLOADED.

The

fol-

lowing safety precautions should be observed:

a

point

gun

directly at the face.

Nevar

put the hand

or

fingers directly over

the spray tip. (Use

of

protective leather gloves

is

recommended.)

Never place

the

tip

or

gun

nozzle directly

in contact with

any

part

of

the body.

lieve material pressure

in

system before attempt-

-

shut

off

air pressure to pump and re-

ing

to

remove

gun

tip

or

screen and/or removing

gun

for

service.

a

remove tip from

gun

to clean

it.

a

tighten threaded connections care-

fully

and

securely, and handle hose carefully to

prevent leaks

that

could cause physical harm same

as pressurized stream

COD~Q

fiom

orifice

in

gun

tip.

the material'to spray

gun

is

properly grounded

to prevent sparking. The high velocity

flow

of

material through the spray tip may cause static

electricity to be developed. Use

only

metal

braid

material dispensing hoses

or

static pro-

tected hose.

Also

be

sure

to provide

for

the

proper grounding out

of

the compressor.

Always

be sure that the equipment supplying

..