PREVENTIVE MAINTENANCE

At

least twice daily and durine any lenethy:

interruption

of

sprayinq,

with

material

pressure

relieved: remove and clean

gun

spray tip and tip

filter

in

clean

solvent

of

a

type recommended by

manufacturer

of the material beine smayed. Blow

~.

~ ~ ~~

_.

.

parts

dry

with

air

pressure.

Also

kerse

gun

nozzle

in

clean

solvent during shut

down

periods.

SHUTDOWN PROCEDURE

To

maintain

efficient operation of unit,

each

day's spraying must be diligently followed:

this

shutdown procedure

at the completion

of

filter cartridge

or

screen,

if

used. Close

drain

valve.

i'rom

spray

gun.

Immerse

in

clean

recornended

bristled brush.

Using the air blower valve

type solvent and

wash

thoroughly with a fine

205-541

attached to air manifold

162-376,

blov

air through tip

from

front to back and through

open end

of

filter.

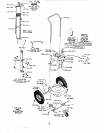

Refer to Fig.

1.

Keep

cotmuended

type

solvent

until ready

to

start

spray

gun

forward end submerged

in

&&

re-

3.

Remove spray tip and filter,

if

used,

spraying again.

NOTE:

Do

not remove the swaq

completely flushed. Keeping

unit

fully

charged

em

from dispensine hose unless the unit

is

to be

..

ON-OFF

air

control petcock

202-338.

See Fig.

1.

1.

Shut off air to pump

by

closing pump

Handle

is

at right angle to petcock body when

closed.

with material

will

minimize~the

necessity for

flushing

unit.

m:

Water based paints

will

requke a

and spray

gun

by

opening

drump

valve of -ifold.

of

all external moving pump

parts

to prevent the

2.

Relieve material pressure in

pump,

hose

,

final flushing with solvent

DAILY

and also

Oiling

This

will

allow

the material trapped in the system

rusting

of

the wetted parts. To completely flush

to

drain

back into material container.

After

ma-

unit

follow

the procedure outlined

in

subsequent

terial has stopped draining, remwe and clean

paragraph entitled

FLUSHINC

UNIT.

-SERVICE

DIAGNOSIS

TROUBLESOME

sIMPpOM.5

CHECK

POINT

NOS.

Fump

fails

to operate,

no

material

discharge.

.............

1-2-3-4-6-9-11

Insufficient material breakup..

..........................

1-3-4-6-6-9

1-24-6-ll

Tails

in

spray pattern............

.......................

Excessive surge

at

spray

gun

2-4-7-Y,

Pump operates, but insufficient material discharge.......

1-2-9-10-12

.............................

..........................

............................

Too

heavy a coating thic.ess

CHECK

POINT

NO.

13

Spray

gun

spitting.............

5-10-11

mssmm

CAUSES

-

l........

Material too viscous

6

........

Air

regllator set too high.

5........

Air

regulator inoperative

or

set too

low.

L........

Air

valve closed

or

clogged.

3........

Insufficient air capacity.

2

........

Restricted

ak.

supply line.

Clogged material filter, tip

or

tip filter.

9........

Clogged materid intake strainer.

e........

Insufficient

material

in

container.

7........

lo........

Worn,

damaged

or

obstructed

gun

parts.

l?........

Surge chamber inactive,

if

used.

12........

Improper

or

worn

spray

gun

tip.

ll........

Hish flow rate-tip orifice too large.

Worn

or

obstructed pump valves

or

packings.

U......,.

MAINTENANCE

IMPORTANT NOTES

1.

Keev unit, mixine container. thinner,

particles rbich could clog strainer screens andl

solvent. and material

CLEAV

and free

of

foreisn

or

plug the small orifice

in

spray tip.

and smav

mn

clean

solvent after

flushin4

unit and until

head immersed

in

recommended type

2.

Keep lower

vump

Assembl-f filled nith

ready to

start

sprayine again.

-3.

TO

reliive-unit

Of

unnecessary pressure

when not in use, shut

off

air pressure to pump

and relieve material pressure

in

system by opening

dump valve

of

manifold

or

filter.

4.

Daily

or

more often

if

experience

in-

dicates necessar

,

drain filter

or

surge tank, re-

more

filter

cart:idne

or

screen.

if

used, and

~

and close dump valve.

7

..

....................