11

307–636

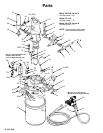

Operation

WARNING

T

o reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

on page 10.

NOTE:

Contact your Graco distributor for information

on training aids available from Graco.

To Operate the Pump

Be

sure the air regulators and bleed–type master air

valve are closed.

DO NOT INST

ALL THE SPRA

Y TIP

YET!

Fill the pail (50) with fluid. Open the bleed–type master

air valve (L) in the main air line, then open the gun air

regulator (B). Hold a metal part of the spray gun (70)

firmly to the side of a grounded metal pail and trigger

the gun. Open the pump’s bleed–type master air valve

(J). Slowly open the pump air regulator (K) until the

pump starts. Allow the pump to cycle slowly until all the

air is pushed out of the fluid lines. Release the gun

trigger and lock the trigger safety; the pump will stall

against the pressure.

With the pump and lines primed, and with adequate air

pressure and volume supplied, the pump will start and

stop as the spray gun is triggered and released.

Relieve the pressure

, then install the spray tip in the

gun (see manual 308–640, supplied).

Use the pump air regulator (K) to control the pump

speed and fluid pressure. Always use the lowest

pressure necessary to achieve the desired results.

Higher pressures waste fluid and cause premature

wear of the pump packings and spray tip.

Keep the wet–cup filled with Graco Throat Seal Liquid

(TSL) or other compatible solvent, to help prolong the

packing life.

Never allow the pump to run dry of the fluid being

pumped. A dry pump will quickly accelerate to a high

speed, possibly damaging itself. If your pump acceler

-

ates quickly

, or is running too fast, stop it immediately

and check the fluid supply

. If the supply container is

empty and air has been pumped into the lines, refill the

supply container and prime the pump and lines with

fluid, being sure to eliminate all air from the fluid sys

-

tem, or flush the pump as described in “Shutdown and

Care”.

AA2000 Spray Gun Operation

Refer

to the OPERA

TION section of manual 308–640,

supplied, for installing the spray tip, adjusting the spray

pattern and using the AA Plus Gun.

Control the air pressure to the gun with the gun air

regulator (B).

Control the fluid pressure to the gun with the fluid

regulator

, if used. Otherwise, adjust the air pressure to

the pump motor to control fluid pressure.

Shutdown and Care

Relieve

the pressure

whenever you shut of

f the

pump. Stop the pump at the bottom of its stroke to

keep fluid from drying on the exposed displacement

rod and damaging throat packings.

Always flush the pump with a compatible solvent

before the fluid can dry on the displacement rod, and

at the end of each day

. If you are pumping water–

based fluid, flush first with water and then with mineral

spirits to protect the pump parts. If you are pumping

oil–based fluids, flush with mineral spirits only

.

Relieve pressure and leave the mineral spirits in the

pump to prevent corrosion.

Manual Air Motor Lubrication

To

lubricate the air motor manually, first

relieve the

pressure

. Then remove the air inlet fitting from the

motor air inlet. Place 10–15 drops of oil in the inlet,

reinstall the air inlet fitting and apply air to the motor

.

Do this daily for the best corrosion protection.