5

308-457

Setup

I. Prepare the operator.

All

persons who operate the system should be trained

in the safe, efficient operation of all system compo

-

nents as well as the proper handling of the chemical

coating. At a minimum, all operators should

thoroughly read the safety

, installation and operation

sections of this manual and the component manuals.

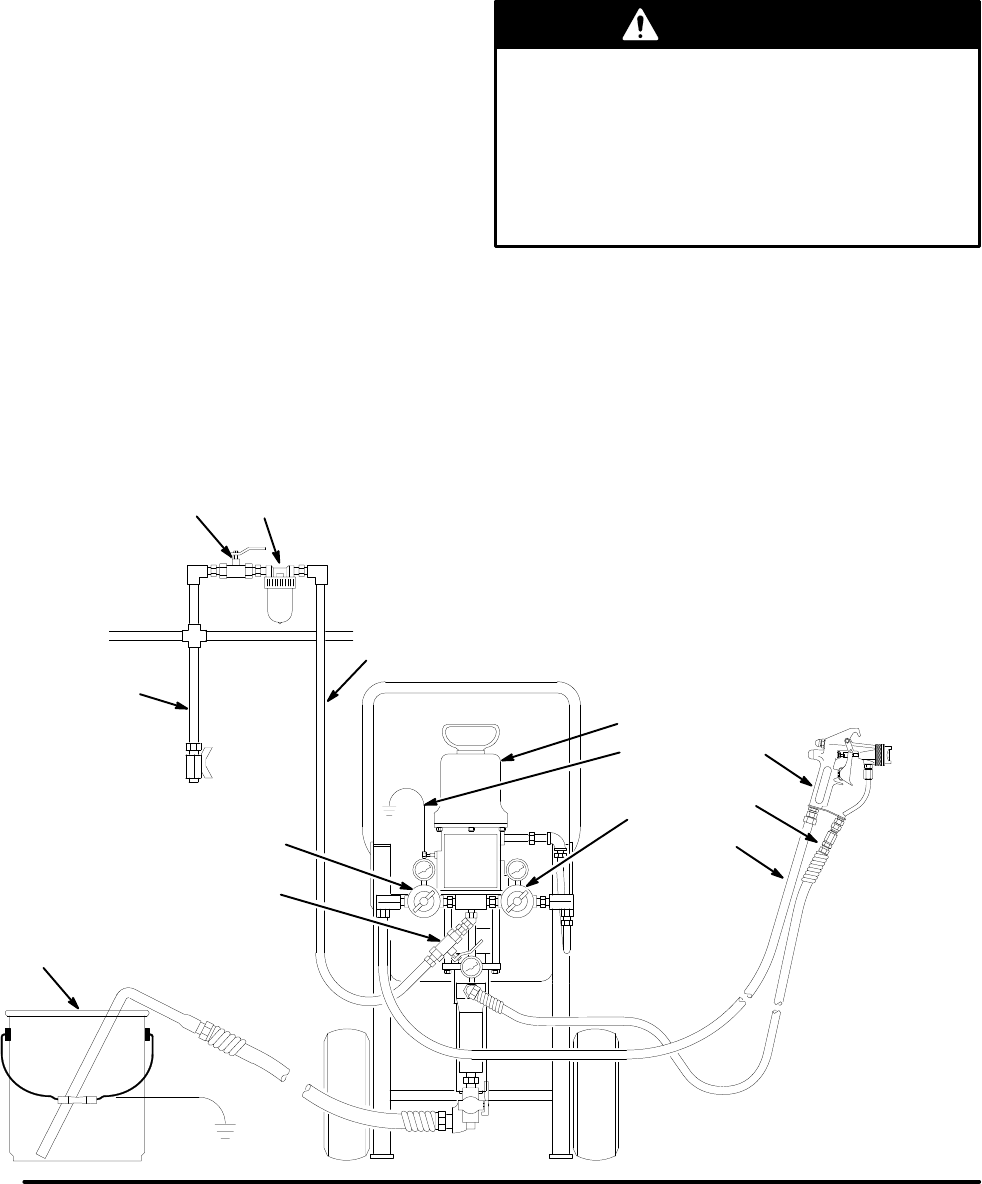

II. Prepare the site.

1. Use

a minimum recommended 5

HP (3.7

kW) air

compressor for ef

ficient operation.

2.

Clear obstacles and debris that could hinder the

operator’

s movement.

3.

Bring an air line from your compressed air supply

to the pump location. Be sure the air is dry and

filtered. Install a bleed–type master air valve (A)

upstream from the pump. Another master air valve

(14) is supplied with the package. When the

bleed–type master air valve is closed and the

pump air regulator (8a) is opened, the valve

relieves all air pressure to the system.

4.

Have a grounded, metal waste–pail available to

use when draining the fluid filter

.

5. V

entilate the spray booth.

WARNING

T

o prevent hazardous concentrations of toxic and/

or flammable vapors, spray only in a properly venti

-

lated spray booth.

Never operate the spray gun

unless ventilation fans are operating.

Check and follow all of the national, state and local

codes

regarding air exhaust velocity requirements.

Fig. 1

A

B

C30

1

8b

8a

04072

KEY

Components

you must supply:

A

Bleed-type master air valve

Required for pump; order

part no. 107–142, 1/4” npt(f)

B

Air filter

. Order part no.

106–149, 1/2 npt(f)

C

Air supply line

D

Grounded 5 gallon metal pail

E

Air line moisture trap

Components supplied with package:

1

23:1 Monark pump

3

Air-assisted airless spray gun

4

Spray tip

6

Gun fluid hose

7

Gun air hose

8a

Pump air regulator

8b

Gun air regulator

14

Bleed–type air valve

30

Pump ground wire

E

6

7

3,4

14

C

D