Maintenance

21

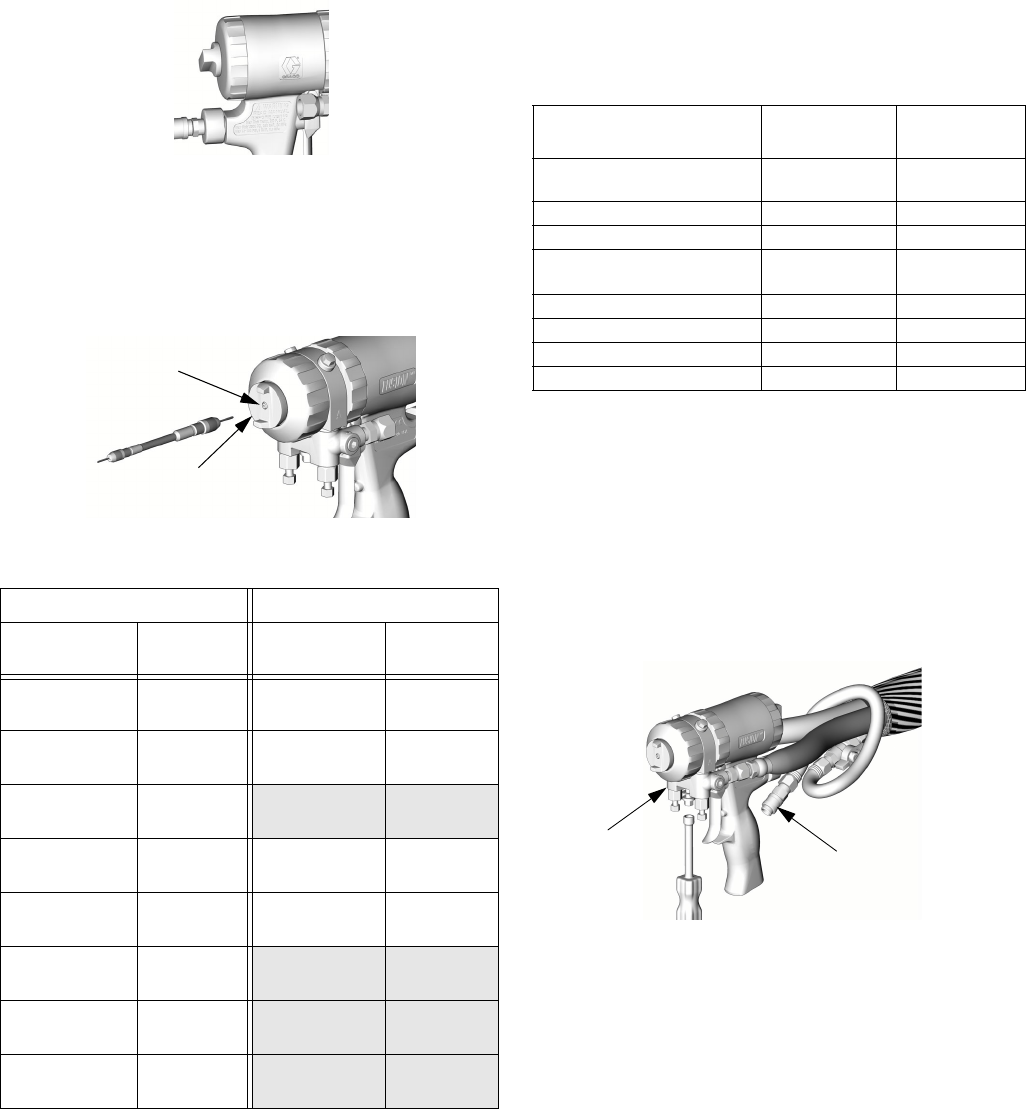

Clean Mix Chamber Nozzle Clean Passages

If necessary, clean out passages in fluid housing and

handle with drill bits. Refer to T

ABLE

2 and to Cutaway

View on page 26 for diameter and location of passages.

All drill bits are available in an accessory kit. Order kit

248969 for Air Purge Handle Drill Kit, see page 40.

Clean Impingement Ports

1.

Engage piston safety lock, page 10.

2.

Refer to T

ABLE

1. Also see identification chart

under Drill Bit Kits, page 39. Use the appropriate

size drill bit to clean mix chamber nozzle (N). If

necessary, clean air cap (C) gently with stiff brush.

Table 1: Nozzle Drill Bit Sizes

Round Spray Flat Spray

Mix Chamber

Part No.

Drill Size

in. (mm)

Mix Chamber

Part No.

Drill Size

in. (mm)

AR2020 #58, .042

(1.00)

AF2020 3/32, .094

(2.35)

AR2929 #55, .052

(1.30)

AF2929 3/32, .094

(2.35)

AR3737 #55, .052

(1.30)

AR4242 #53, .060

(1.50)

AF4242 3/32, .094

(2.35)

AR5252 #50, .070

(1.75)

AF5252 3/32, .094

(2.35)

AR6060 #44, .086

(2.15)

AR7070 3/32, .094

(2.35)

AR8686 #32, 0.116

(2.90)

TI2409A

N

TI2418A

C

Table 2: Passage Diameters

Passage Description

Ref. Letter

(page 26)

Diameter,

in. (mm)

Optional Air Inlet C 7/16, 1/8

(11.0, 3.1)

Purge Air D 1/8 (3.1)

Piston Air E, F 1/8 (3.1)

Air Exhaust G 11/32, 1/8

(8.7, 3.1)

Air Valve Bore H 9/32 (7.1)

Cleanoff Air Not Shown 3/32 (2.35)

Check Valve Holes Not Shown 3/32 (2.35)

Grease Not Shown 3/32 (2.35)

1.

Follow Pressure Relief Procedure, page 15.

2.

Disconnect air (D) and remove fluid manifold (M).

3.

Flush Gun, page 20. If gun will not flush, see page

29.

4.

Remove Front End, page 27.

TI2554A

M

D