Setup

312414D 7

Setup

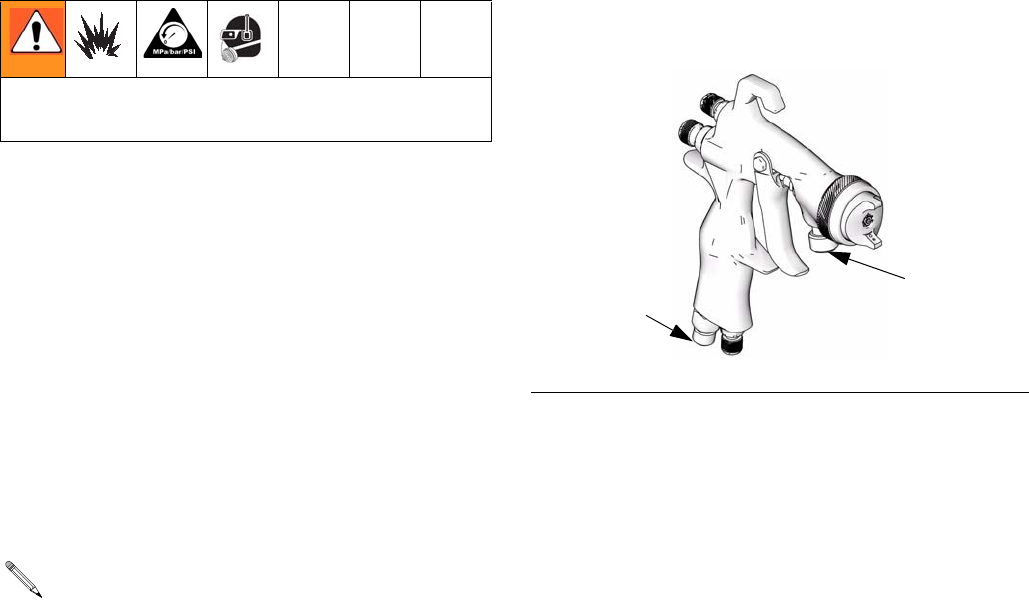

Connect Air and Fluid Lines

1. Shut off the air supply.

2. Install a shutoff valve (not supplied) down-

stream of the air regulator to shut off gun

air.

3. Install an inline air filter (not supplied) to

clean and dry the gun air supply.

4. Connect a clean, dry, filtered air supply to

the air inlet fitting. See FIG. 1.

5. Connect a fluid hose to the fluid inlet fitting.

See FIG. 1.

6. Connect other end of the fluid hose to a

regulated fluid supply line.

Ground the Gun

Check your local electrical code and pump

manual for detailed grounding instructions.

Ground the spray gun through connection to a

Graco-approved grounded fluid or air supply

hose.

Flush Before Using Equipment

The equipment was tested with lightweight oil,

which is left in the fluid passages to protect

parts. To avoid contaminating your fluid with

oil, flush the equipment with a compatible sol-

vent before using the equipment. See Flush,

page 10.

At least one hose must provide a static

ground to the gun.

• Recommended 5/16 in. (7.9 mm) ID

hose, optional 3/8 in. (9.5 mm) ID hose.

• Check that your shop air provides ade-

quate air flow. See Technical Data,

page 23, for minimum cfm

requirements.

• Set shop air pressure regulator (not

supplied) according to fluid manufac-

turer’s recommendation. See maximum

compliant air pressure on air cap.

• Make sure no air restrictions, such as

low-volume cheater valves, obstruct the

air flow.

FIG. 1

air inlet

fluid inlet

ti11094a