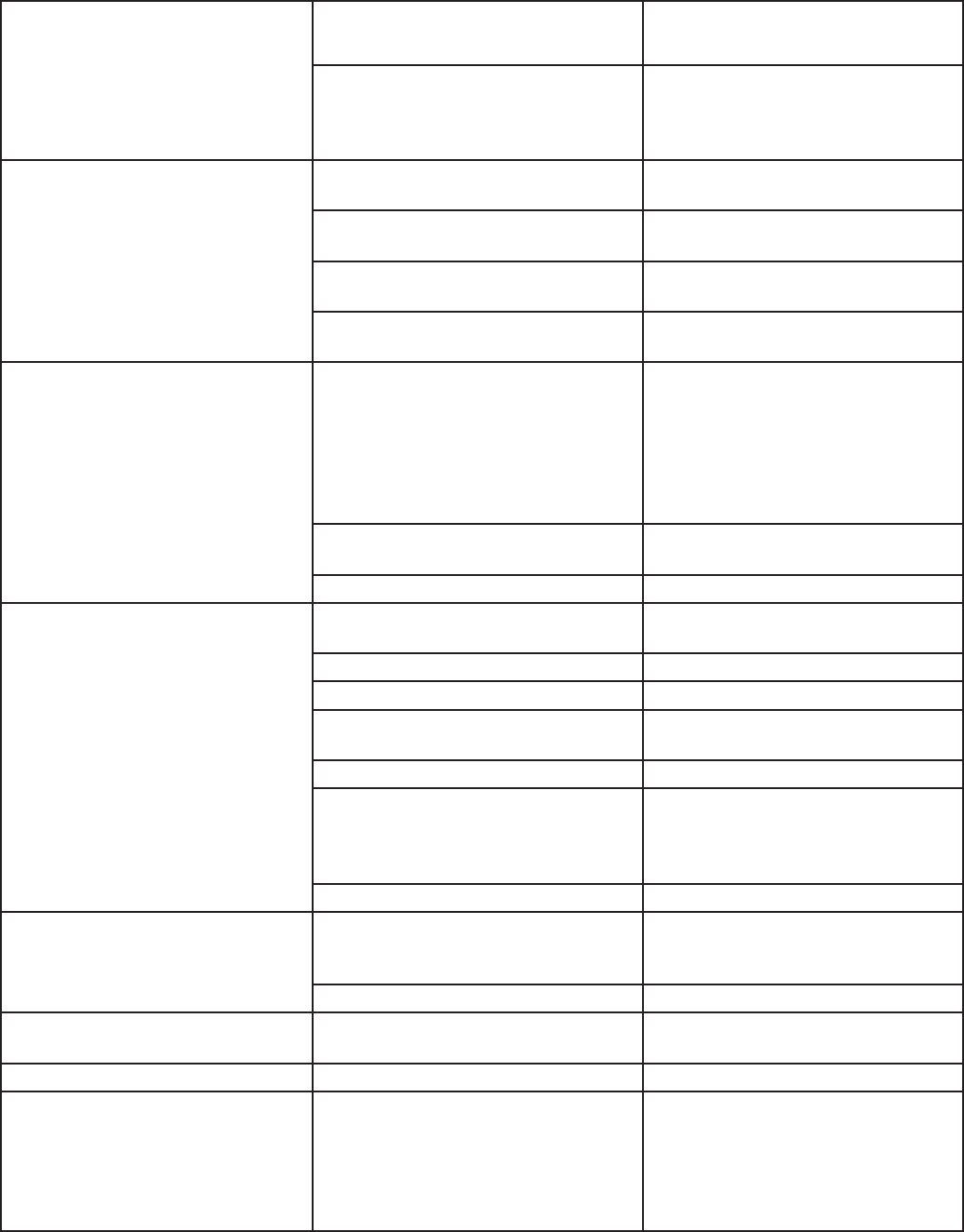

Engine will not start. Various engine problems. Refer to the engine manual accom-

panying your unit.

Low engine oil level. Engine is equipped with an Oil Alert

System which will not allow the

engine to start if oil level is low. Add

oil, if needed.

Noisy operation. Loose engine pulley or pump y-

wheel.

Tighten pulley and or ywheel.

Lack of oil in the pump. Add correct amount of oil. Check

for bearing damage.

Carbon deposits on pistons or

valves.

Remove cylinder head and inspect.

Clean or replace.

Bearing, piston or connecting rod

failure.

Stop the air compressor. Contact

Graco Customer Service.

Pressure drop in air tank or rapid

pressure loss when air compres-

sor is shut off.

Air leaks at connections. Allow air compressor to build

pressure to the maximum allowed.

Turn off and brush a soapy wa-

ter solution onto all connections.

Check connections for air bubbles.

Tighten the connections where

leaks are present.

Air leak in air tank. Air tank must be replaced. DO NOT

attempt to repair air tank.

Defective Pilot Valve. Clean or replace.

Insufcient pressure at air tool or

accessory.

Pressure Regulator not turned to

high enough pressure or defective.

Adjust Pressure Regulator to

proper setting or replace.

Restricted air intake. Clean or replace Air Intake Filter.

Air leaks or restrictions. Check for leaks and repair.

Hose or hose connections are too

small or long.

Replace with larger hose or con-

nectors.

Slipping belt. Tighten or replace.

Air compressor is not large enough

for air requirement.

Check the accessory air require-

ment. If it is higher than the CFM or

pressure supply to the air compres-

sor, use a larger air compressor.

Restriction in Pilot Valve Clean or replace.

Air leaks from Safety Relief Valve. Possible defective Safety Relief

Valve.

Operate Safety Relief Valve manu-

ally by pulling on ring. If it still

leaks, it should be replace.

Excessive air tank pressure. Clean, reset or replace Pilot Valve.

Air leaks at pump. Defective gaskets. Torque head bolts: Single Stage=17

ft./lbs. Two Stage=33 ft./lbs.

Air blowing from Air Intake Filter. Defective inlet (reed) valve. Contact Graco Customer Service.

Moisture in discharge air. Condensation in air tank caused by

high level of atmospheric humidity

or air compressor is not run long

enough.

Run air compressor a minimum of

one hour to prevent condensation

buildup. Drain air tank after every

use. Drain air tank more often in

humid weather and use an air line

lter.