14 308842

Bearing Housing and Connecting Rod

Replacement

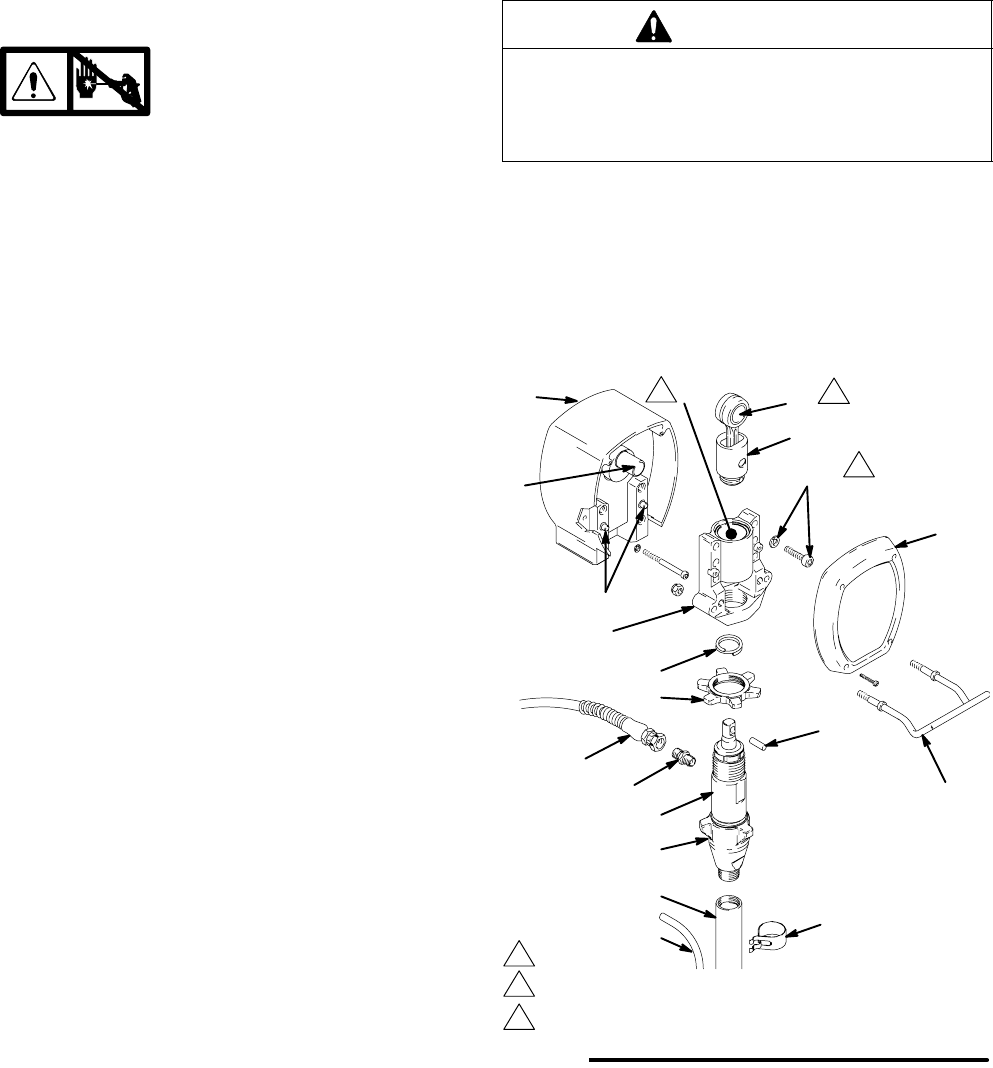

1. Read General Repair Information on page 3.

2.

Relieve pressure; page 3.

3. Stop sprayer at bottom of stroke to get crank (E) in

lowest position.To lower crank manually, carefully

rotate blades of fan with a screwdriver.

4. Fig. 8. Remove front cover (49). Unclip drain hose

(36) from pump. Unscrew pump suction tube (39)

pump intake valve (213). Disconnect pump hose

(70).

5. Push up retaining spring (68). Push pin (66) out

rear.

6. Loosen locknut (47). Unscrew displacement

pump (64).

7. Remove four screws and lockwashers (25,23).

8. Tap lower rear of bearing housing (22) with a

plastic mallet to loosen from drive housing (67).

Pull bearing housing and connecting rod assembly

(63) straight off drive housing.

9. Remove pail bracket assembly (F) and install it on

new bearing housing.

10. Inspect crank (E) for excessive wear and replace

parts as needed. Evenly lubricate inside of bronze

bearing (B) with high quality motor oil. Pack roller

bearing (C) with bearing grease.

11. Assemble connecting rod (63) and bearing housing

(22).

12. Clean mating surfaces of bearing and drive hous-

ings (22, 67).

13. Align connecting rod (63) with crank (E) and drive

housing locating pins (G) with bearing housing (22)

holes. Push bearing housing onto drive housing or

tap into place with plastic mallet.

CAUTION

Do not use bearing housing screws (25) to align or

seat bearing housing; this may cause bearing and

drive housing misalignment and result in premature

bearing wear.

14. Install screws and lockwashers (25, 23). Tighten

screws evenly to 175 in-lb (19 Nm).

15. Install pump; page 17.

16. Fig. 8. Install remaining parts.

Fig. 8

22

67

25, 23

49

68

66

64

E

Torque to 175 in-lb (19 Nm)

70

47

63

B

C

F

40

Pack with bearing grease

Oil

85

213

G

39

36

7698B

3

2

1

1

2

3