Operation

311052H 13

For a narrower pattern, supply air to the gun fan air inlet

(or open the fan adjustment valve on manifold 288223).

The tip size is the primary controller of the pattern size.

Use the fan air only as needed to slightly adjust the pat-

tern size.

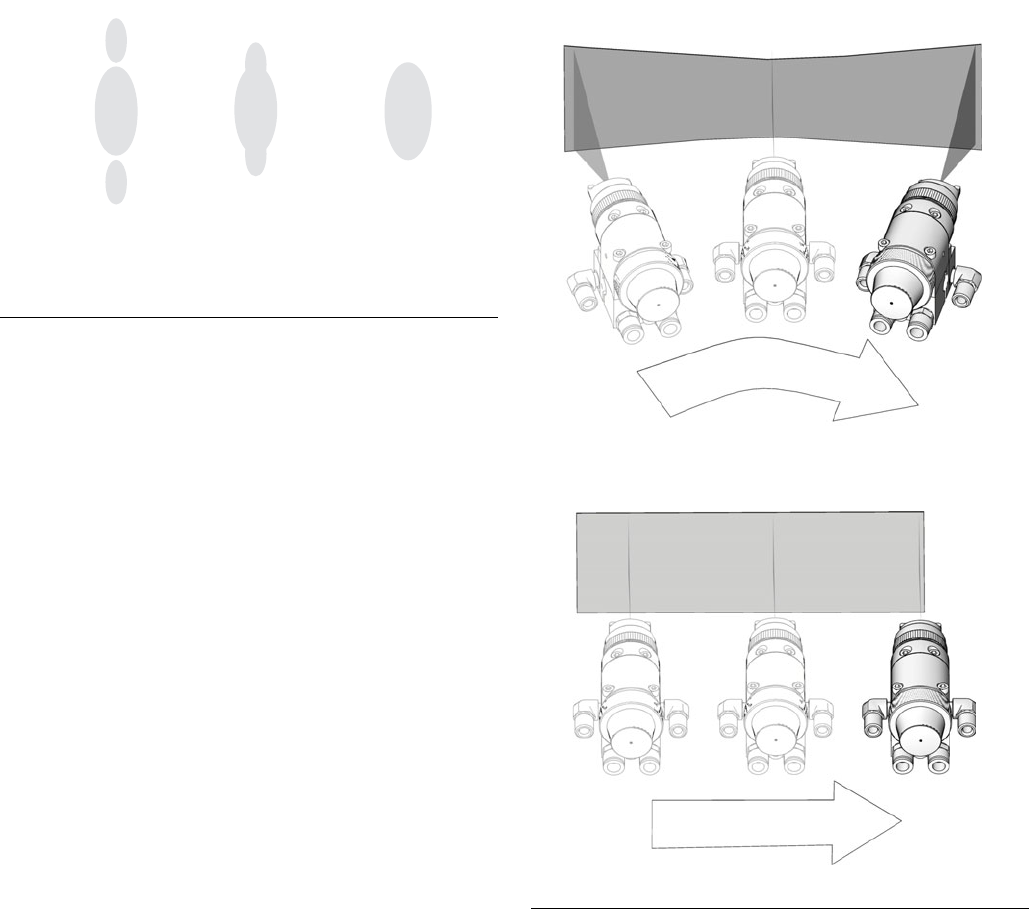

Apply Fluid

The spray gun has a built-in lead and lag operation.

When triggered, the gun begins emitting air before the

fluid is discharged. When the trigger actuation air is

stopped, the fluid stops before the air flow stops. This

helps assure the spray is atomized and prevents fluid

buildup on the air cap and tip.

Adjust the system control device, if it is automatic, so the

gun starts spraying just before meeting the work piece

and stops as soon as the work piece has passed. Keep

the gun a consistent distance, 8 to 10 inches (200 to 250

mm), from the surface of the object being sprayed.

To achieve best results when applying fluid:

• Keep gun perpendicular and 8 to 10 inches (200 to

250mm) from object being sprayed.

• Use smooth, parallel strokes across surface to be

sprayed with 50% overlap. See F

IG. 12.

F

IG. 11: Correct Spray Pattern

no air

too little air correct amount

of air

TI0792

FIG. 12: Correct Spray Method

Incorrect

Correct

TI8098a

TI8099a