NOTE: When increasing to a wide, flat pattern,

increase supply of fluid to gun to maintain

same coverage over larger area.

Direction of spray pattern (horizontal or vertical) is

changed by loosening lock ring and turning air cap to

the desired position. TIGHTEN LOCK RING HAND

TIGHT. DO NOT OVERTIGHTEN.

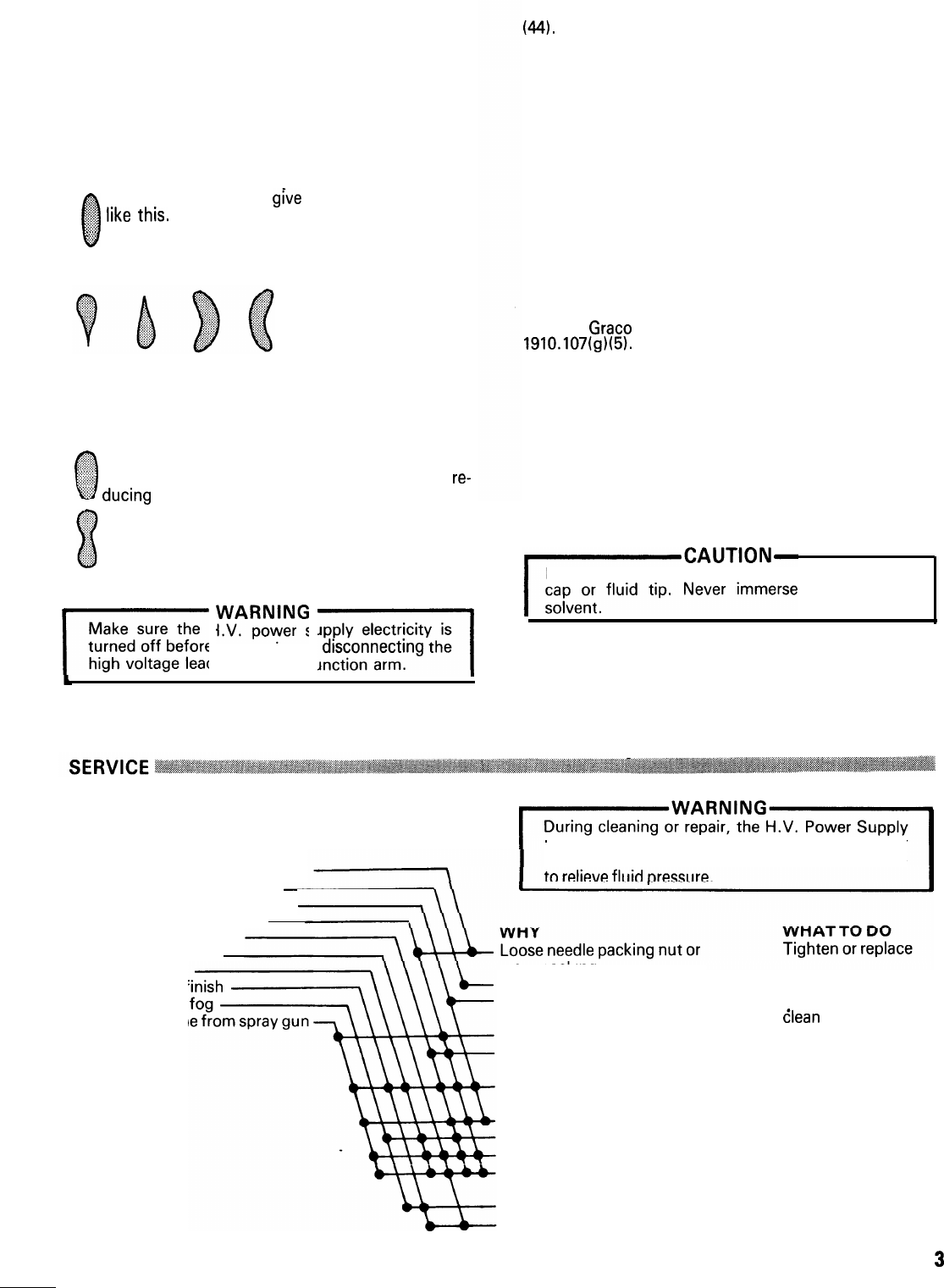

Normal Spray Pattern

.::>:

0

Proper adjustment will grve a spray pattern shaped

##

Iike

this.

$$:i:

$:::.

Improper Spray Patterns

Heavy on top or bottom, right or left. Caused by

paint buildup on air cap or fluid tip, partially plug-

ged air holes or fluid tip. To remedy, clean the cap

or tip.

&$

Heavy in the center. Caused by too much, or too

0

@$

thick material. To remedy, reduce flow by

re-

<is?

ducing fluid pressure or thinning the paint.

Split pattern. Caused by insufficient paint, or too

much air pressure. To remedy, increase fluid

pressure or reduce air pressure.

Make sure the H.V. power supply electricity is

I

WARNING

I

turned off before connecting or drsconnectrng the

high voltage leads at guns or junction arm.

Connect high voltage cable to the high voltage adapter

(44.

When all adjustments are made, -trigger air, atomizing

air, fluid pressure, and fan pattern,-you can turn on

the high voltage and begin operation.

Care of Gun

Good housekeeping is important. Clean the gun and

work area daily. A buildup of conductive residue on

either exterior or interior surfaces of gun may interfere

with proper operation.

Flush out the gun with an approved solvent at the end

of the work day. Wipe the outside of the gun with an

approved gun cleaner. Remove the air cap and clean it.

If ionizing wire of needle (41) is bent after cleaning,

straighten wire so that it is centered in fluid stream. For

an approved solvent or gun cleaner, see your local sup-

plier or Grace Branch. Also, refer to OSHA 29 CFR

1910.107(g)(5).

Cleaning

After each spraying operation, turn off the high voltage

power supply, and solvent flush until all remaining paint

is removed from hose and gun.

If air cap needs cleaning, remove and soak in clean

compatible solvent (not over 15 minutes) and scrub with

a fine bristled brush. To clean out holes in air cap, use a

toothpick or other soft implement.

Never use metal instruments to clean holes in air

entire gun in

TROUBLESHOOTING CHART

WHAT’S WRONG

Fluid needle packing nut leakage

Air leakage from front of gun

Fluid leakage from front of gun

Spitting or fluttering spray

Defective spray pattern

“Orange Peel” finish

must be turned off. Before removing air cap or

spray tip, shut down paint pump and trigger gun

Streaks in finish

Runs or sags in f

Excessive spray

Fluid won’t corn

worn packing

Air valve not seating properly

Fluid needle not seating

properly

Fluid low

Loose fluid tip or damaged

seat

Loose air cap, dirty or damaged

fluid nozzle or air cap

Needle worn or damaged

Too much air pressure

Insufficient air pressure

Poorly mixed and/or strained

fluid

Fluid thinned out too much

Improper thinner

Clean,lubricate,service

Loosen packing nut,

clean

or replace

Check fluid supply

Tighten,clean,replace

Tighten,clean,clear

replace

Replace

Use least necessary

Increase air pressure

Properly mix and

strain

Properly thin fluid

Use proper thinner

307434

3