should be taken when starting threads. Applied

vide you with years of durability and efficiency

These working parts require periodic replacement:

1. Air cap (7).

2. Fluid tip (6).

3. Needle, fluid (41).

Removing Fluid Tip

To remove fluid tip (6) for cleaning or replacement,

remove the ring nut (8) and air cap

(71,

turn off the

atomizing air, trigger the gun to release needle pressure

on the tip. Remove the tip with a wrench. Replace with

the needle triggered to the rear.

When replacing air cap

(7)

on the gun, be sure the wire

electrode coming from the needle

(41)

is centered in the

air cap center hole. The best method is to slide the air

cap onto fluid housing

(51,

making sure that the wire

goes through center hole of air cap, then tighten ring

nut

(8),

onto barrel

(42)

allowing air cap to be drawn up

evenly on the fluid tip. Check alignment of ionizing wire

in the fluid stream.

Removing Fluid Tip Housing

If the housing

(5)

is removed, the o-rings

(2)

should be

replaced and the housing firmly seated. The housing

must be torqued no more than 15-20 ft-lb

(20

N-m), or

plastic threads may become stripped. Lubricate with

petroleum jelly new o-rings on housing before replacing

in gun barrel.

NOTE: Fluid tip (6) must be removed from housing

before replacing to avoid damage to ionizing

wire.

Replacing Fluid Needle

Turn off the atomizing air and fluid, trigger the gun to

release needle pressure on the tip. Remove ring nut

(8)

and air cap

(7).

Remove fluid tip

(6)

with a 7/16 in.

wrench. Remove nut

(19)

and screw

(31)

from the rear

of the gun. With a long nose pliers pull out needle ex-

tension

(46),

nut

(291,

nut

(301,

spring

(331,

and needle

(41).

Unscrew needle

(41)

from extension (46). (Pliers

maybe necessary as Loctite is used on threads.) Install

new needle

(411,

applying Locrite no. 290 or equivalent

to threads to prevent needle from coming loose during

operation. Reassemble needle into back of gun using

extreme care. Ionizing wire must remain straight as it

passes through rear actuator packings

(18).

After needle is assembled in the gun, replace fluid tip

(6)

and rear spring

(33)

and spring

(341,

along with ad-

justing screw

(311,

locknut

(19)

and air cap

(7).

For ad-

justment see Replacing Fluid Needle Extension.

Replacing Needle Guide

Needle guide (47) is pressed into rear of fluid housing

(5). Remove fluid housing and press out needle guide.

When replacing be sure internal chamfered end faces

rear of fluid housing.

Replacing Fluid Needle Extension

Remove needle (see Replacing Fluid Needle). When

replacing extension (46); locknut

(29)

and needle ad-

justing nut

(30)

must be readjusted on needle extension.

Push needle

(41),

needle extension

(46)

and piston

(38)

fully forward, and turn the adjusting nut

(30)

all the way

into the piston. Remove needle assembly from piston,

turn adjusting nut two turns counterclockwise, and

tighten locknut (29). This adjustment provides atom

izing

air just before the fluid needle is engaged and after

seating.

Replacing Fluid Packing

The fluid packing

(23)

is replaced when the needle

(41)

is removed. Remove the packing nut

(22)

then pick out

the packing and replace. Replace the packing nut. In-

sert the fluid needle, tighten the packing nut and apply

pressure on the packing to a firm seating. Do not

over-

tighten. The fluid needle should move without binding.

When the gun is completely assembled and fluid

pressure applied, the packing nut may be tightened to

correct a slight leak.

Removing Gun Barrel

It is seldom necessary to remove the gun barrel (42)

from the gun body

(37).

When necessary, this is ac-

complished by unscrewing the gun coupling

(8)

and

carefully lifting away from the gun body. Inspect o-rings

(I and 4) and replace if necessary. To line up guide pin

in barrel with hole actuator assembly keep indicator de-

tent intop of barrel lined up with top of actuator.

Replacing Cylinder Adapter

The cylinder adapter

(43)

should not be removed unless

damaged.

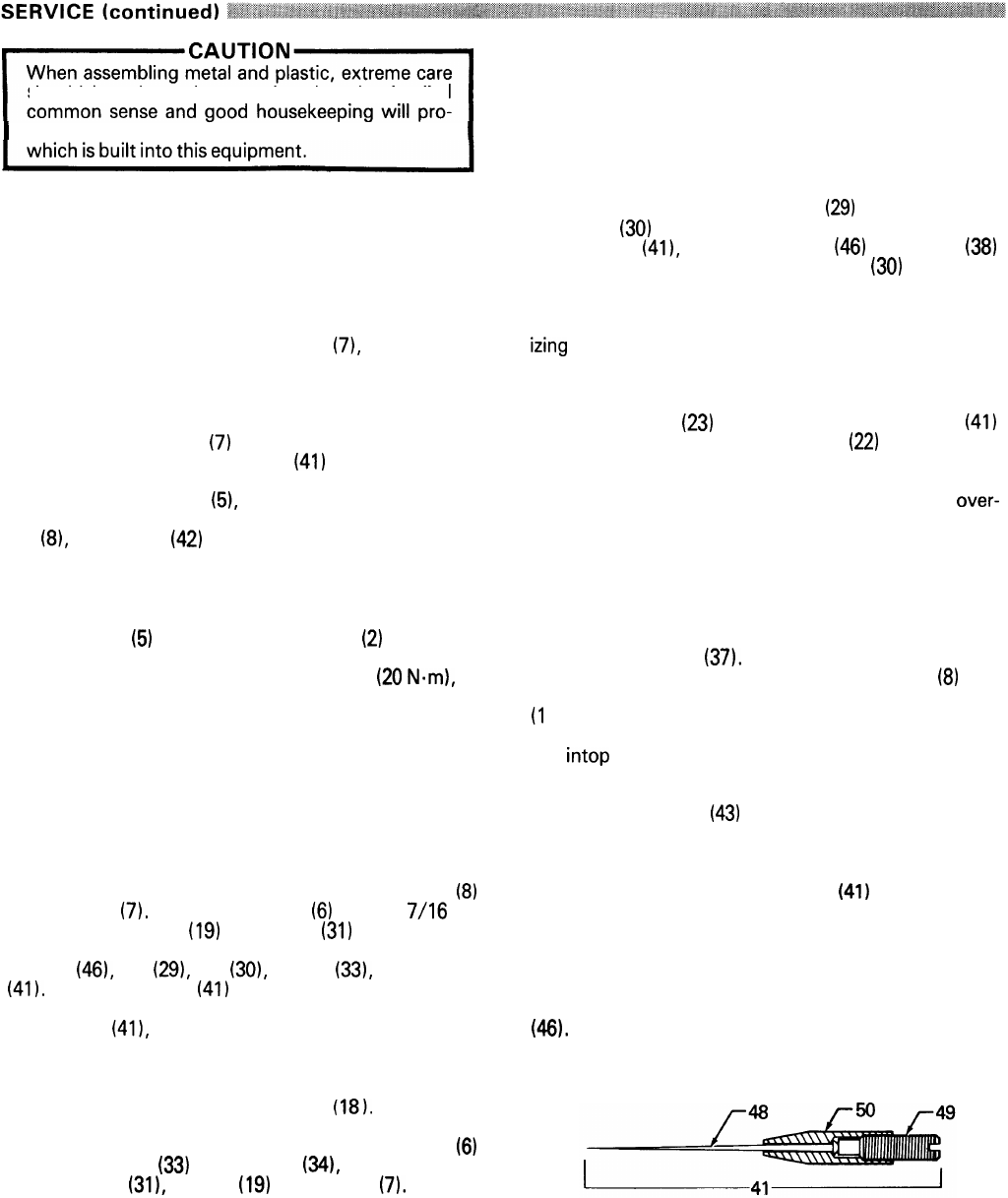

Replacing Electrode Stem of Fluid Needle

If electrode stem (48) of fluid needle

(41)

needs replace-

ment, first unscrew electrode stem from fluid needle ex-

tension (46). Unscrew setscrew, and remove old elec-

trode stem.

Insert new electrode stem and replace setscrew.

Reassemble fluid needle (41) to fluid needle extension

Ma

4 307434