8 308–367

Operation

Starting and Adjusting the Pump

WARNING

To

reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

on page 7.

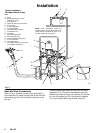

See Fig. 5. Be sure the air regulators (F

, G) and bleed-

type master air valve (B) are closed.

Do not install

the spray tip yet.

On cart mount units,

place the suction tube (7) in the

fluid container

.

On wall mount units,

screw the bung adapter (18) into

the container

’

s bung hole. Slide the suction tube

assembly (J) through the bung adapter and into the

container

. Position the tube so the intake housing (1) is

about 1/2 in. (13 mm) of

f the bottom of the container

.

T

ighten the thumbscrew (26) to secure.

On pail mount units,

fill the pail (46) with fluid. Set the

cover (36) on the pail and secure with the latches (40).

Open the drain valve (H) to prime the pump. Open the

bleed-type master air valve (B). Open the gun air

regulator (G). Hold a metal part of the spray gun firmly

to the side of a grounded metal pail and trigger the

gun.

Slowly open the pump air regulator (F) until the pump

starts. Run the pump slowly until fluid comes from the

drain valve (H). Close the drain valve and continue to

run the pump until all the air is pushed out of the fluid

lines. Release the gun trigger and engage the safety

latch; the pump will stall against the pressure.

With the pump and lines primed, and with adequate air

pressure and volume supplied, the pump will start and

stop as the spray gun is triggered and released.

Relieve the pressure,

then install the spray tip in the

gun.

Use the pump air regulator (F) to control the pump

speed and fluid pressure. Always use the lowest

pressure necessary to achieve the desired results.

Higher pressures waste fluid and cause premature

wear of the pump packings and spray tip.

Keep the packing nut/wet-cup filled with Graco Throat

Seal Liquid (TSL) to help prolong the packing life.

Check the tightness of the packing nut weekly

. The

packing nut should be tight enough to prevent leakage

– no tighter

. Always

relieve the pressure

before

adjusting the packing nut.

Never allow the pump to run dry of the fluid being

pumped. A dry pump will quickly accelerate to a high

speed, possibly damaging itself. If you pump acceler

-

ates quickly

, or is running too fast, stop it immediately

and check the fluid supply

. If the supply container is

empty and air has been pumped into the lines, refill the

supply container and prime the pump and lines with

fluid, being sure to eliminate all air from the fluid sys

-

tem, or flush the pump as described in

Shutdown and

Care

, below

.

Shutdown and Care

WARNING

To

reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

on page 7.

Always

relieve the pressure

whenever you shut of

f

the pump. Stop the pump at the bottom of its stroke to

keep fluid from drying on the exposed displacement

rod and damaging the throat packings.

Always flush the pump with a compatible solvent

before fluid can dry on the displacement rod, and at

the end of each day

.

Relieve the pressure

after

flushing.