6 309489

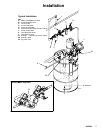

Installation

NOTE: Reference numbers and letters in parentheses

in the text refer to callouts in the figure illustrations and

the parts drawing.

The T ypical installation shown on page 7 is only a

guide to electing and installing require d and optional

accessories. For assistance in designing a system to

suit your needs, contact your Graco representative.

Mount the pump to suit the type of installation planned.

The pump dimensions and mounting hole layout are

shown on page 17.

Pail and Drum Length Pumps

Install the pump in the drum or pail, using a suitable

cover, bung adapter, or mounting clamp. The pump

must be 1/2 in. (13 mm) off the bottom of the pail or

drum.

The pump has a by--pass tube, route the tube back to

the supply container.

NOTE: In a closed-head drum, be sure to loosen the

vent plug in the drum cover to prevent formation of a

vacuum.

WARNING

An accessory is required in your system: a bleed-

type master air valve (A). This accessory helps

reduce the risk of serious injury including injection,

splashing in the eyes, and injury from moving parts

if you are adjusting or repairing the pump.

The bleed-type master air valve relieves air trapped

between this valve and the pump after the air

regulator is shut off. T rapped air can cause the

pump to cycle unexpectedly. Locate the valve close

to the pump.

The fluid drain valve (part of the Evenflo

r air

regulator installed on pump) assists in relieving

fluid pressure in the displacement pump, hose, and

gun; triggering the gun to relieve pressure may not

be su f ficient.

Evenflor Automatic Pressure Cont rol

An Evenflor air regulator installed on the pump has a

Relax-A-Valve. This regulator prevents initial surg ing of

non-atomized fluid when the gun is triggered. Air

pressu re in the pump is relieved automatically each

time the gun trigger is released. When used with a

Relax-A-Valve set in the automatic position, fluid

pressu re is relieved automatically also. Refer to the

Evenflor Automatic Pressure Manual for additional

information.

All Pumps

Install the air line accessories in the approximate order

shown in the Typical Installation drawing. A pump

runaway valve (B) senses when the pump is running

too fast and shuts off the air supply to the motor. For

automatic air motor lubrication, install an air line lubri-

cator (D). (For manual lubrication, see Maintenance on

page 10). Install the bleed-type master air valve (A)

within easy reach of the pump. Install an air regulator

(E) to control air to the motor and pump speed. An air

line filter (C) removes harmful dirt and moisture from

your compressed air supply.

Be sure that the air supply hose is properly grounded,

and is at least 1.2 in. (13 mm) ID in order to supply an

adequate volume of air to the motor.

Connect a suitable grounded fluid hose and spray gun

or dispensing valve to the pump’s 3/4 in. npt outlet.