14 GC-1388F

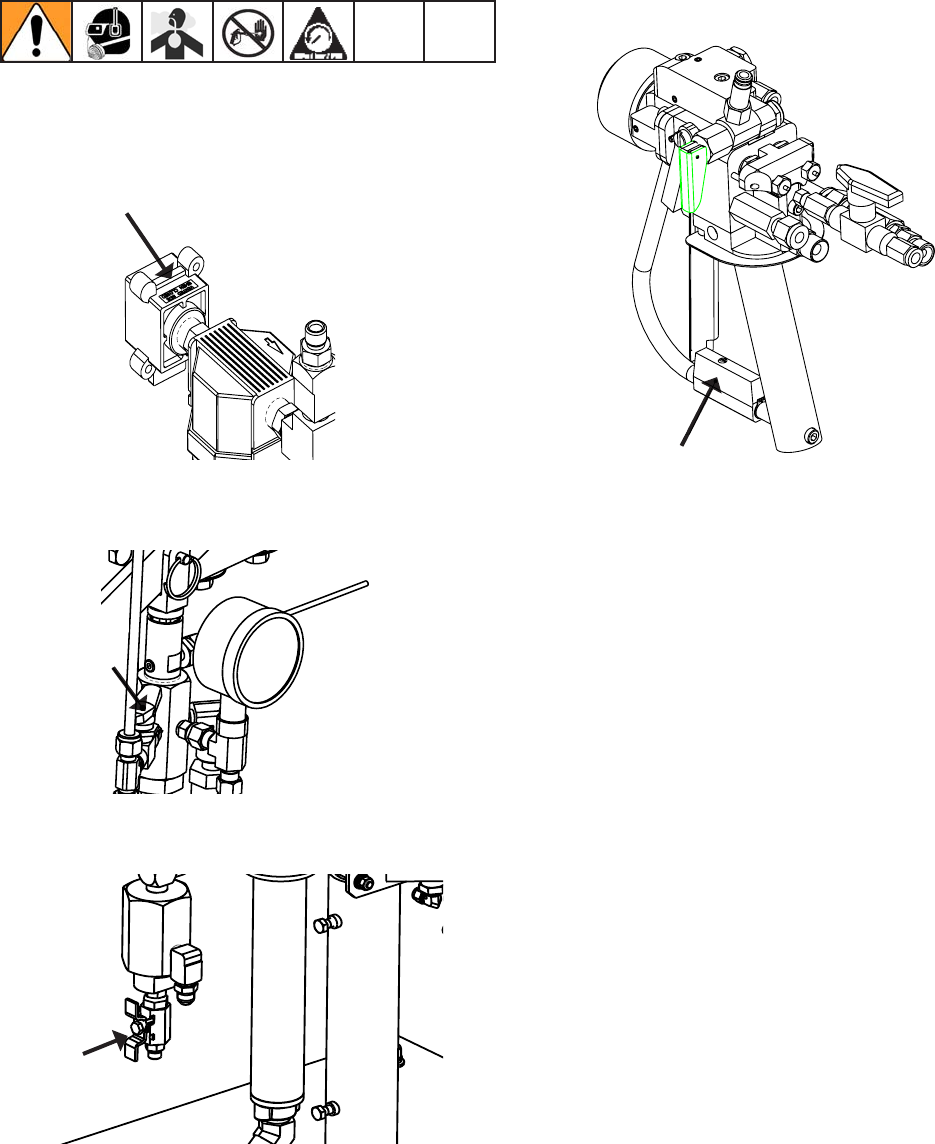

To relieve uid and air pressures:

1. Push down Yellow slide valve, P/N 21402-00 to bleed

off air to system.

2. Open P/N 21228-00 on catalyst pump to recirculation

position.

3. Open P/N 21192-00 on bottom of material pump.

4. Verify the Trigger Lock is in the Locked position.

Daily Maintenance

It is recommended that the following service be per-

formed on a daily basis.

1. The Gun is built at the factory with, P/N 21222-00

Lubricate. This is a water soluble lubricate, not

affected by most solvents. When maintaining the

Gun, it is recommended that this is used as outlined

on “Lubricate Page”. Clean the Gun using a brush

and a appropriate clean solvent.

2. Inspect Gun Valve Needle shafts, making certain

they are clean and free of over-spray or foreign-

material. Clean and lubricate as required.

3. Inspect the Gun Packings, Needles and Seats for

catalyst or material leakage. If leakage does occur,

correct at once! If material leaks (or drips) out of the

nose of the gun, this indicates that there is a bad needle

/seat condition. If material leaks out of the back of the

needle stem, this indicates loose or worn packings

and may be repacked by tightening the packing nuts,

P/N 20509-00 1/8 turn each until leak stops. Test trigger

to verify spring can return needle to seat.

4. Maintain a reasonable stock level of “wear” items

such as Packings, Seals and O-Rings

5. If dispense gun is leak tested, be sure to dry gun

thoroughly.

6. Never leave dispense gun immersed in any liquid.

Pressure Relief Procedure