5 310584D

T1-TITANIUM NON-HVLP SPRAY GUN

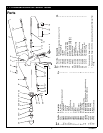

Troubleshooting

Technical Data

Maximum Air and Fluid Inlet Pressure: 100 psi (0.7 MPa,

7 bar)

Air Consumption:

• Part No. 5430: 11 CFM at 50 psi (345 kPa, 3.4 bar)

• Part No. 5435: 13.8 CFM at 50 psi (345 kPa, 3.4 bar)

Wetted Parts: stainless steel, carbon steel, aluminum, PTFE,

low density polyethylene

Weight: 1 lb. 3 oz. (0.54 kg)

Spray Gun

• 1/4 npsm (R1/4-19) air inlet

• 3/8 npsm (R3/8-19) fluid inlet

WARNING

Follow Pressure Relief Procedure, page 3, before troubleshooting or servicing. Read warnings, page 2.

Problem Cause Solution

Normal pattern No action necessary

Dirty or damaged air cap or fluid nozzle. Rotate air cap 180°.

If pattern follows air cap, problem is in air cap. Clean and

inspect. See page 4. If pattern is not corrected, replace air

cap.

If pattern does not follow the air cap, the problem is with the

fluid nozzle. Clean and inspect the nozzle. See page 4. If the

pattern is not corrected, replace nozzle.

Pressure too high for viscosity of material

being sprayed.

a. Reduce air pressure and increase fluid pressure.

b. Increase material viscosity

c. Correct pattern by narrowing fan size with spray width

adjustment knob.

Dirty or distorted air horn holes. Rotate air cap 180°.

If pattern follows air cap, problem is in air cap. Clean and

inspect. See page 4. If pattern is not corrected, replace air

cap.

Will not spray. Fluid adjustment knob (16) turned too far

clockwise.

Adjust knob (16) to the counterclockwise.

a. Fluid pressure too high for viscosity of

material being sprayed.

a. Reduce fluid pressure.

b. Air pressure too low. b. Increase air pressure.

c. Gun held too close to surface. c. Hold gun about 6-8 inches (150-200 mm) from surface.

Right

Wrong

Heavy top or

bottom pattern

Wrong

Split pattern

Wrong

Wrong

Heavy pattern or

orange peel