-8-

H8151 230V Mini Welder

Grounding for Arc

Welding Safety

There are two or more electrical circuits involved

in any welding operation. The practice of safely

grounding these circuits is documented in vari

-

ous codes and standards (refer to

Additional

Sources for Welding Codes and Standards

on

Page 6).

Welding Machine Ground

When properly connected to a power source, the

Model H8151 welder is grounded through the

power cord and power grid. The welder's inter

-

nal welding circuit is insulated from the external

enclosure. However, to avoid shocking hazards in

the event that this internal insulation should fail,

you must establish a separate earth ground for

the welder's external enclosure. This will ensure

that the metal enclosure of the welder and the

internal welding circuit are at the same electrical

potential.

Note: Refer to the publication NFPA 70, National

Electric Code, Article 250, Grounding, and your

local electrical codes for the correct method of

establishing this ground.

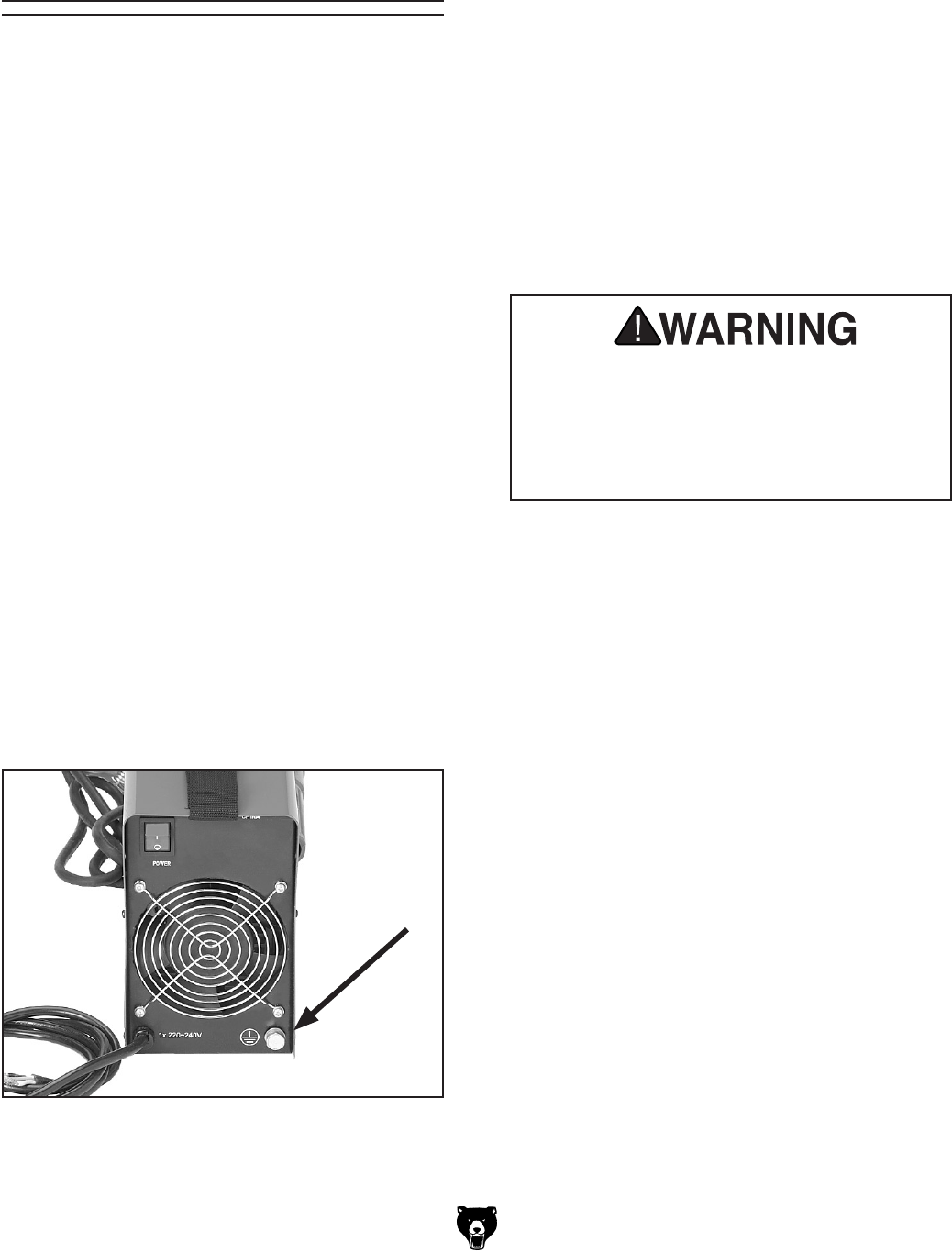

The grounding terminal for the H8151 external

enclosure is located on the right rear of the welder

(see Figure 4).

Figure 4. Location of external enclosure

grounding terminal on the rear of the Model

H8151.

Workpiece Ground

The incoming power circuit to the welder and

the welding circuit are two separate circuits that

must have separate grounds. The welding circuit

consists of the internal components of the welder,

the welding cables, the electrode holder, the work

clamp, and the workpiece.

In the publication Safety in Welding, Cutting,

and Allied Processes, ANSI Publication Z49.1,

11.3.2.1, it is specified that "Grounding [of the

workpiece] shall be done by locating the work on

a grounded metal floor or platen, or by connection

to a grounded building frame or other satisfactory

ground."

Always ensure that the ground for the incom-

ing power circuit to the welder and the

ground for the welding circuit are never con

-

nected. Failure to comply with this warning

could result in serious property damage,

personal injury, or death.

However, you must also avoid "double grounding"

of the workpiece. The ANSI Publication Z49.1

publication warns that "Care shall be taken to

avoid the flow of welding current through a con

-

nection intended only for safety grounding since

the welding current may be of a higher magnitude

than the grounding conductor can safely carry."

Note: The work lead from the welder is some-

times incorrectly referred to as the "ground lead."

The work lead from the welder is NOT a ground

.

The work lead and the ground connection to the

workpiece are separate and must NOT be con

-

nected in any way.