G0445/G0582/G9962Z/9962ZX Wide Belt Sander -29-

Tools Needed: Qty

14mm Open End Wrench ..................................

1

Small Snap Ring Pliers .....................................

1

6mm Hex Wrench ..............................................

1

#2 Phillips Screwdriver .....................................

1

Eventually the brake pads will wear out. Checking

and replacing these is a simple project that can

be done in the shop, with the exception of having

the rotor resurfaced on a lathe.

To check the brake pads:

1. DISCONNECT THE SANDER FROM THE

POWER SOURCE AND REMOVE AIR

PRESSURE COMPLETELY!

2. Remove the four screws that secure the

access panel on the right-hand side of the

machine.

3. The brake caliper is located underneath the

rotor, which is attached to the motor arbor.

4. The brake pads consist of a metal plate with

a composite pad. With a fine ruler, measure

the thickness of the composite pad only. If

one of the pads is below

1

⁄8" (approx. 3mm),

replace both.

To replace the brake pads:

1. DISCONNECT THE SANDER FROM THE

POWER SOURCE AND REMOVE AIR

PRESSURE COMPLETELY!

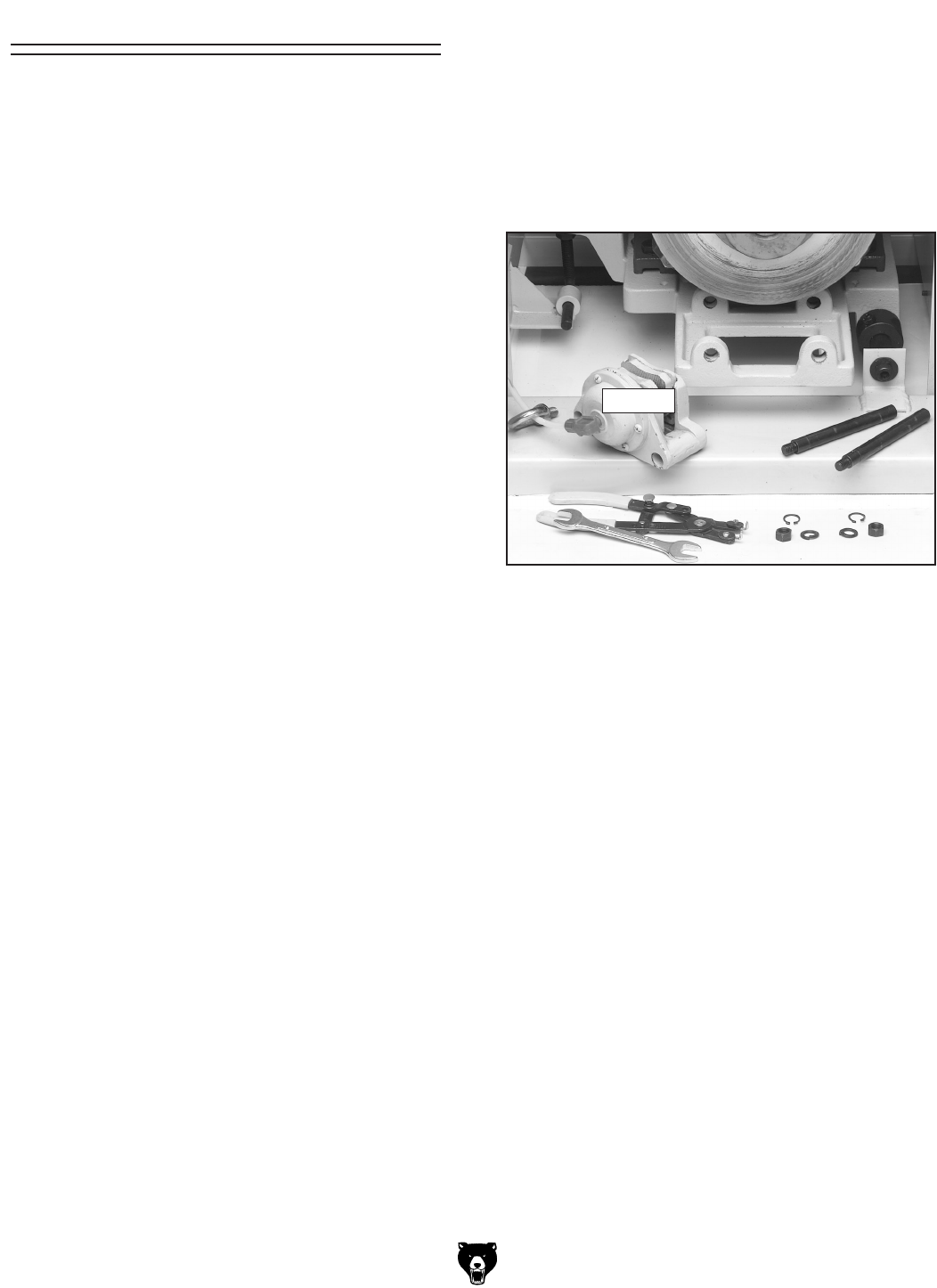

2. Remove the nuts from the two mounting

bolts and the two snap rings on the mounting

pins behind the bracket (see

Figure 24).

3. Pull the mounting pins out of the caliper

bracket and remove the air line from the

caliper. The caliper should now be able to be

removed.

4. Disassemble the brake caliper and remove

the cap screws securing the brake pads.

5. Remove the brake rotor and have it profes-

sionally resurfaced at an automotive machine

shop if it has gouges in it. If visible cracks are

present in the brake rotor, replace it with a

new one. Remove oil and dirt from the rotor

with automotive brake cleaner. Once clean,

only handle the rotor with a dry rag and

install exactly the reverse of removal.

6. Install new brake pads, mount the caliper

and reconnect the air line.

7. Test the safety shutdown operation by run-

ning the sander and pressing the emergency

stop controls.

Brake Service

Figure 24. Disc brake.

Caliper