-18- 18" & 20" Super Heavy-Duty Bandsaws

Figure 17. Guide bearings properly adjusted.

The guide bearings ensure that the blade cannot

twist during operation. Perform the steps below

for both upper and lower guide bearings.

To adjust the guide bearings:

1. Carefully tighten the guide adjustment knobs

until the guide bearings just touch the blade

on each side as in

Figure 17

. Do not deflect

the blade while making this adjustment and

do not over-tighten!

2. Tighten each of the jam nuts.

Ideally, the guide bearings should have 1 or 2

thousandths (0.001-2") clearance from the blade

and should not pinch the blade. The blade could

become hot and deformed if excessive pressure

is applied by the guide bearings. The system

employed by this bearing assembly will give

clearance for the blade when the jam nuts are

tightened. Make sure the jam nuts are tight before

starting the machine.

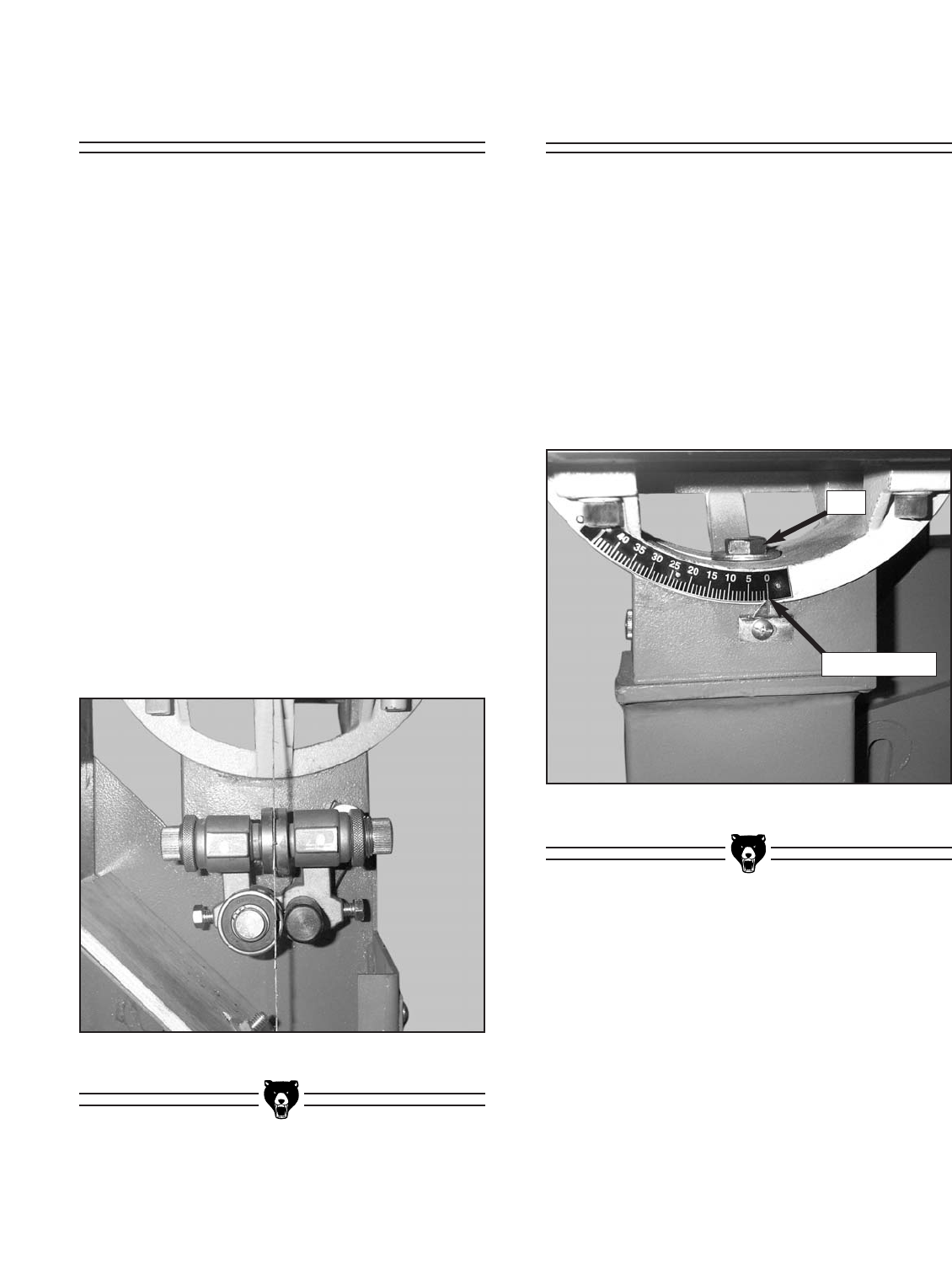

Guide Bearings Table Tilt

To tilt the table:

1. Loosen the large hex bolt under the table

and in the center of the table trunnion as

shown in

Figure 18

.

2. Tilt the table to the desired angle. Use the

angle gauge for easy reference.

3. Tighten the large hex bolt in the center of the

table trunnion.

Figure 18. Loosen the bolt to tilt the table.

Angle Gauge

Bolt