"'-"

<%*%.<%*%.<&+m)%AVi]Z

Feed Rod and

Leadscrew

Gearbox Ratio

Levers

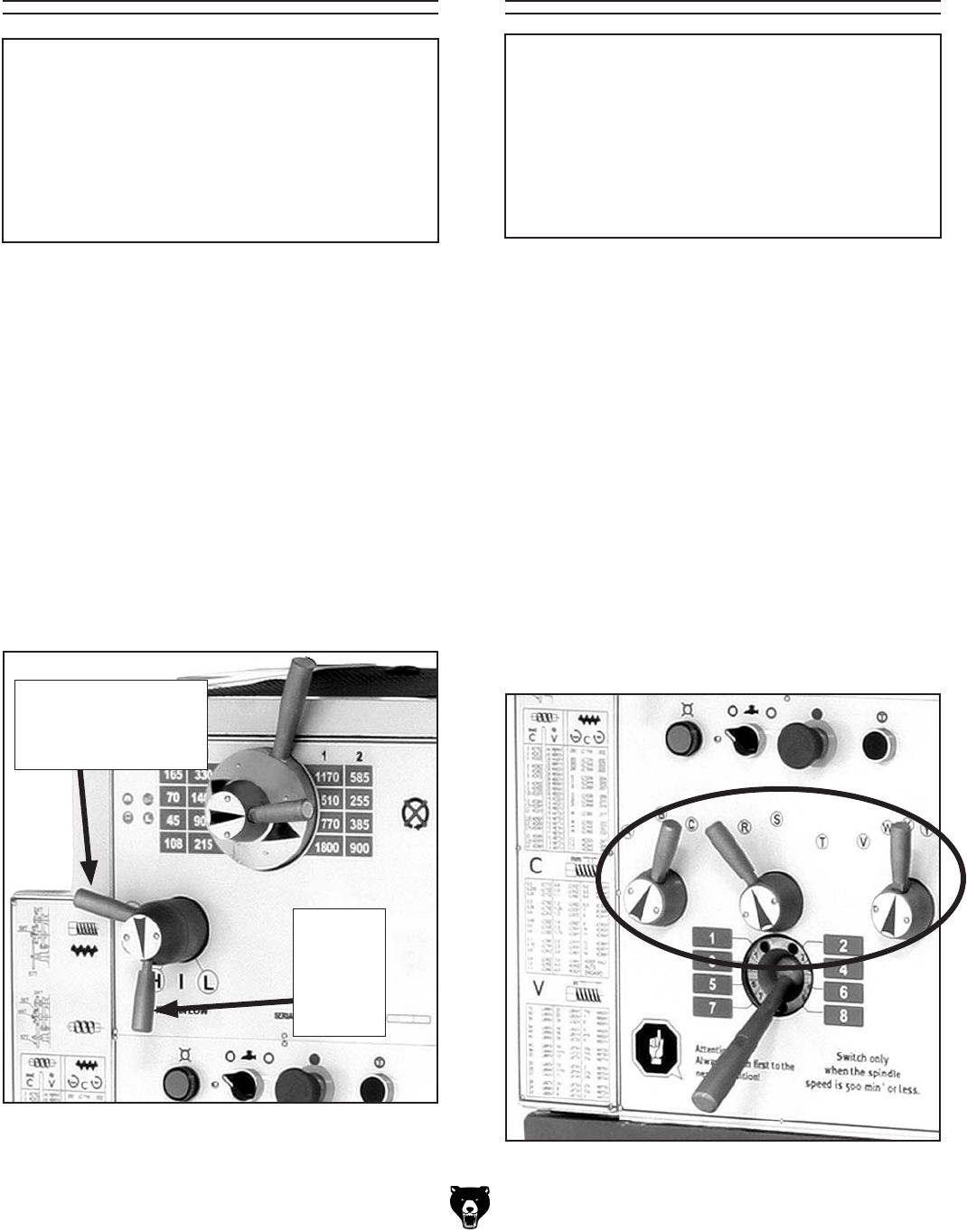

I]ZaZVYhXgZl$[ZZYgdYaZkZgFigure 21 Zc\V\"

Zh VcYY^hZc\V\Zh i]ZaZVYhXgZl VcY[ZZY gdY

h^bjaiVcZdjhan# L]Zc i]Z aZkZg ^h bdkZY je dg

Ydlc!i]ZgdiVi^dcd[i]ZaZVYhXgZlVcY[ZZYgdYh

VgZh^bjaiVcZdjhangZkZghZY#

I]Zi]gZZ"edh^i^dc \ZVgWdm]^\]$adlgVc\Z aZkZg

Figure 21l^aaeji i]Z \ZVgWdm ^cid]^\]gVc\Z

H!adlgVc\ZL!dgcZjigVaI#

Note: Make sure to loosen the carriage lock

(Figure 28) when apron power feed or threading

are to be used. The carriage lock is used only to

increase carriage stability when facing operations

are in process.

NOTICE

ONLY shift the gearbox levers when spindle

speed is less than 500 RPM and the gear-

box speed range lever is in neutral. NEVER

force a lever. If the lever will not engage, use

the jog button when applicable so the teeth

mesh and the lever drops into position.

Figure 21. <ZVgWdm^cejiVcYdjiejiXdcigdah#

AZVYhXgZl$;ZZY

GdY9^gZXi^dcAZkZg

Djieji

<ZVgWdm

=^\]$Adl

GVc\Z

AZkZg

>ceji

Figure 22. <ZVgWdmgVc\ZaZkZgh#

NOTICE

ONLY shift the gearbox levers when spindle

speed is less than 500 RPM and the gear-

box speed range lever is in neutral. NEVER

force a lever. If the lever will not engage, use

the jog button when applicable so the teeth

mesh and the lever drops into position.

I]Z\ZVgWdm]VhVhZg^Zhd[aZkZghjhZY[dgXdc"

igdaa^c\i]Z[ZZYgdYVcYaZVYhXgZl[ZZYgViZh^c

gZaVi^dch]^el^i]i]Zhe^cYaZheZZY#

7VhZYdci]Zi]gZVY^c\VcY[ZZYgViZX]Vgi!ndj

XVch]^[ii]Z\ZVgWdmidVXXdbbdYViZVcZaVWd"

gViZVggVnd[[ZZYgViZh#I]Zi]gZZ\ZVgWdmgVc\Z

aZkZgh Figure 22 ]VkZ bjai^eaZ aZiiZgZY edh^"

i^dch Figure 24! VcY l]Zc bdkZY VXXdgY^c\

idi]Z i]gZVY^c\ X]Vgi VcYZmVbeaZ dci]Z cZmi

eV\Z!ndjXVcfj^X`anX]Vc\Zi]Z[ZZYgViZ#I]Z

ZmVbeaZdci]ZcZmieV\Zh]dlhi]ZaVi]ZhZije

idXjiV"3.5mm"i]gZVYjh^c\i]ZLCR8YaZkZg

XdbW^cVi^dc#

Note/ The change gear must be in the position

shown inFigure 23#