"')"

BdYZa<%,'%GB[\#H^cXZ&&$&%

Headstock Travel

(Z-Axis & Rotation)

Ndjgb^aa]VhVYdkZiV^aZYXdajbci]ViVaadlhndj

idgZedh^i^dci]Z]ZVYhidX`Vadc\i]ZO"Vm^hVcY

X]Vc\Zidda^c\l^i]djiadh^c\ndjgVa^\cbZcil^i]

V ]daZ dg b^aa^c\ eVi]#;dg Vc\aZY b^aa^c\ deZgV"

i^dch!i]Z]ZVYhidX`XVcWZgdiViZYaZ[iVcYg^\]i

)*#

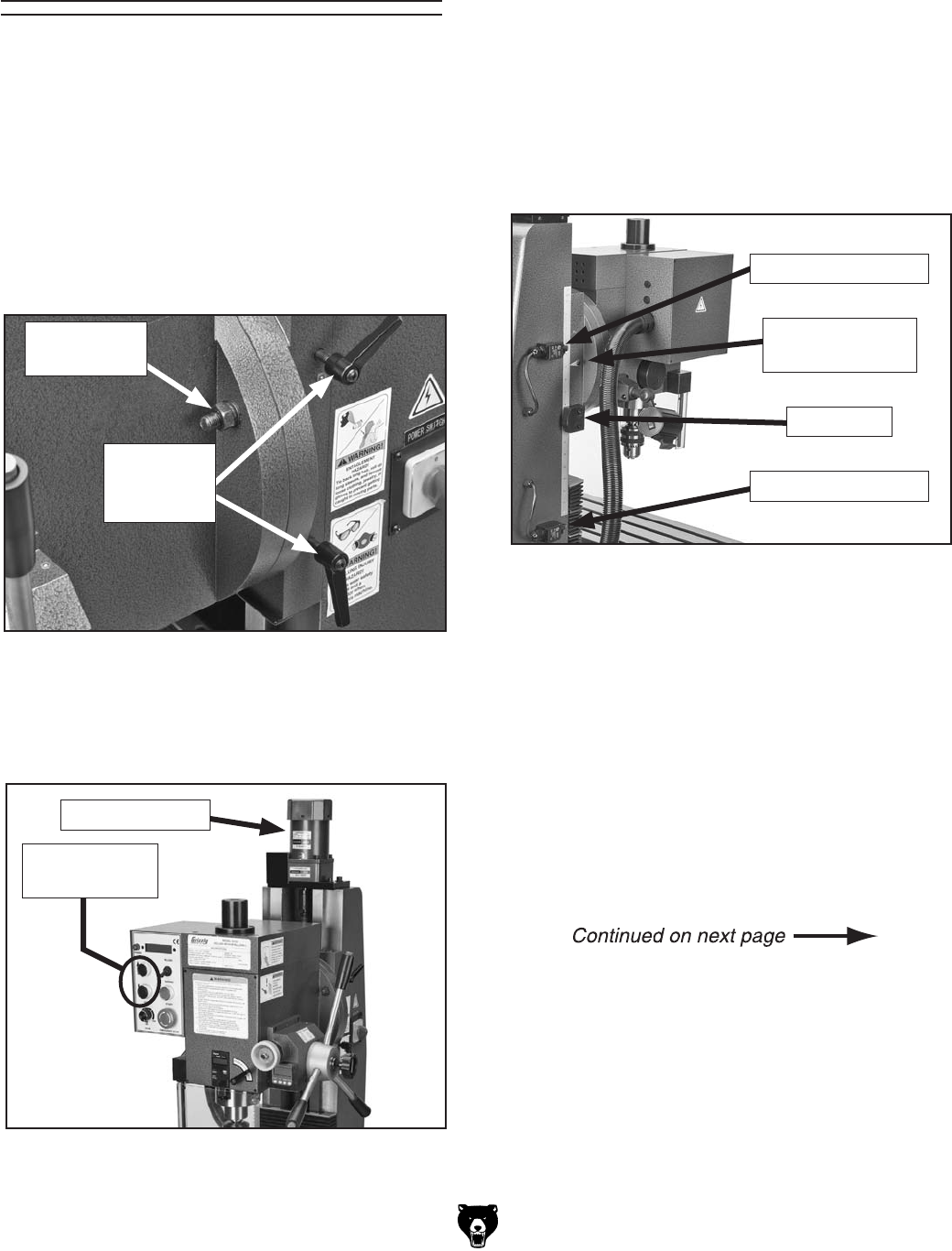

Raising & Lowering

1. JcadX`i]Z]ZVYhidX`ha^YZadX`aZkZgh]dlc

^cFigure 18#

3. DWhZgkZ i]Z ]Z^\]i hXVaZ dc i]Z aZ[i h^YZ

Xdajbch]dlc^cFigure 20 idYZiZgb^cZi]Z

]ZVYhidX`igVkZa#I]^hhXVaZ^hWgd`ZcYdlc

^c

&

¿-\gVYjVi^dch#

Note: When the headstock reaches a point

of travel where the leadscrew has run out of

thread, a stop block (see Figure 20) contacts

either the upper or lower limit switch to stop

the elevation motor from over running the

physical limitations of the leadscrew length,

which would cause damage.

AdlZgA^b^iHl^iX]

JeeZgA^b^iHl^iX]

Hide7adX`

:aZkVi^dcHXVaZ

VcYEd^ciZg

Figure 20. 8dajbchl^iX]ZhVcYhXVaZ#

Note: For maximum spindle rigidity when

milling, keep the spindle retracted into the

headstock as far as possible with the quill

lock lever locked and with the fine feed lock

knob tightened.

2. Dci]ZXdcigdaeVcZaejh]i]ZJEdg9DLC

WjiidchhZZFigure 19idgV^hZdgadlZgi]Z

]ZVYhidX`l^i]i]ZZaZkVi^dcbdidg#

Figure 19. O"Vm^hXdcigda#

Figure 18. =ZVYhidX`ha^YZXdcigdah#

JeVcY9dlc

7jiidch

:aZkVi^dcBdidg

=ZVYhidX`

Ha^YZAdX`

AZkZg

=ZVYhidX`

I^ai=ZmCji