-14- G1019 14'' Bandsaw

V-Belt

1. The weight of the motor against the V-belt

should offer adequate belt tension. Adjust

the motor parallel to the axis of the upper

drive shaft/pulley and tighten the motor

mount bolts.

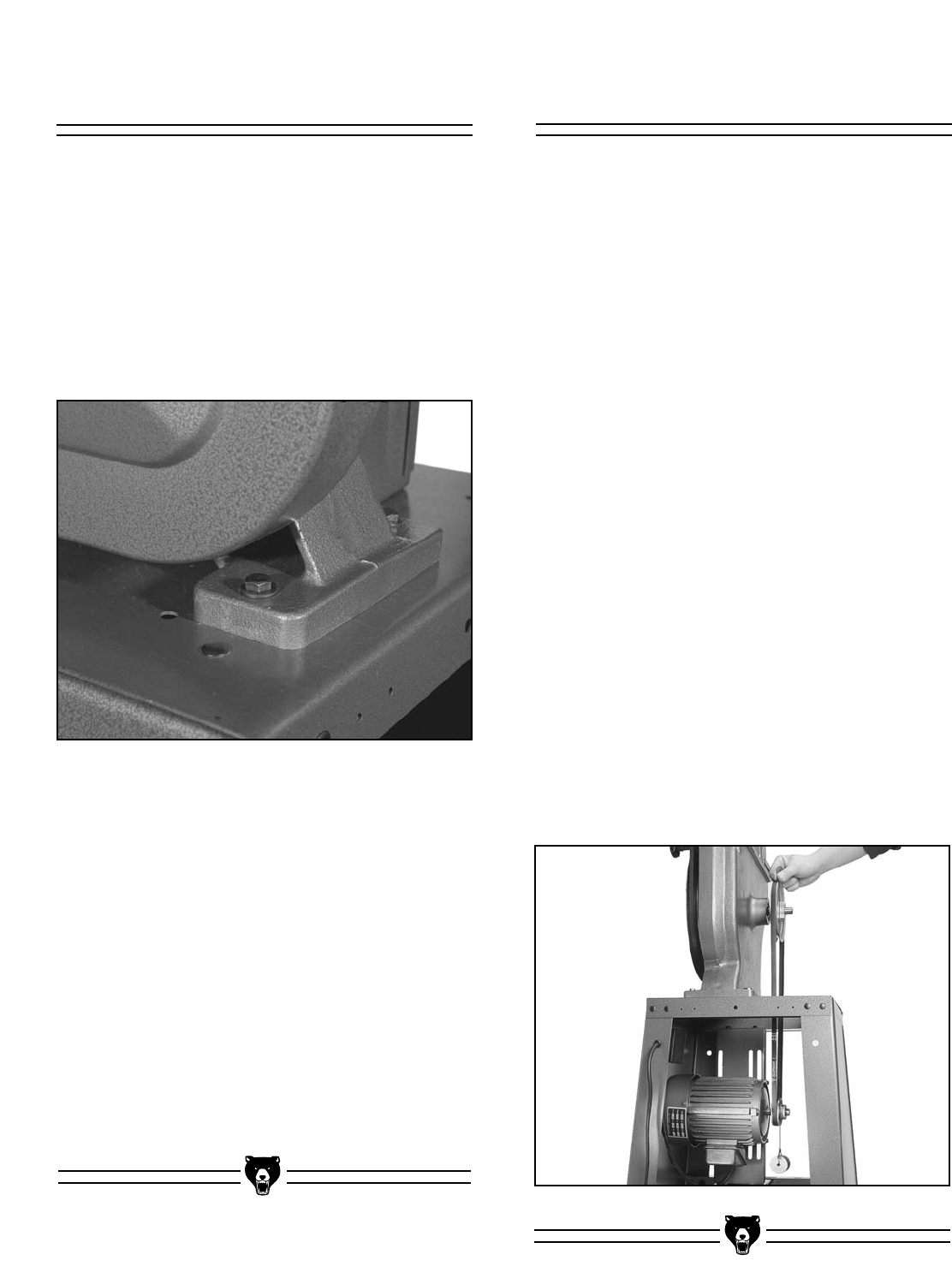

2. The upper and lower pulleys must be

aligned with each other to prevent pre-

mature V-belt wear. Set a straight edge (or

a plumb bob if saw is level) against the

upper pulley. If the straightedge touches

both pulleys evenly, the pulleys are aligned.

If the straightedge does not touch both pul-

leys evenly, the pulleys are not aligned. See

Figure 15.

3. Three options are available when aligning

pulleys depending upon the amount and

nature of the misalignment:

A. Loosen one or both of the pulley setscrews

on their shafts and slide the pulleys in or out

along their shafts.

B. Rock the motor clockwise or counter-clock-

wise in relation to the upper drive shaft/pul-

ley.

C. Moving the lower portion of the motor mount

bracket in or out.

Remember to retighten the setscrews and bolts

when finished.

Figure 15. Aligning pulleys with plumb bob.

Bandsaw To Stand

1. Place the bandsaw unit on the stand and

align the 4 holes in the base over the 4

mounting holes in the stand. Get help with

this step as the bandsaw unit is very heavy

and awkward for one person to handle.

2. Loosely secure the bandsaw base to the

stand with the four (4)

5

⁄16"-18 x 1

1

⁄2" hex

bolts, nuts, and washers provided. See

Figure 14.

Figure 14. Loosely fasten to base.

3. The large drive pulley is installed from the

factory.

4. Loosen the motor mount bolts. Lift the

motor up high enough to slip the V-belt over

both pulleys. Set the motor back down to

the end of its travel. V-belt alignment and

tensioning will be covered in the next sec-

tion.

5. Move the bandsaw back and forth on the

stand to ensure that the bandsaw stand is

seated properly. Ensure that the stand is

symmetrical when viewed from the front

and the side. Tighten all fasteners except

for the motor mount bolts.