-11- G1036 Slow-Speed Grinder

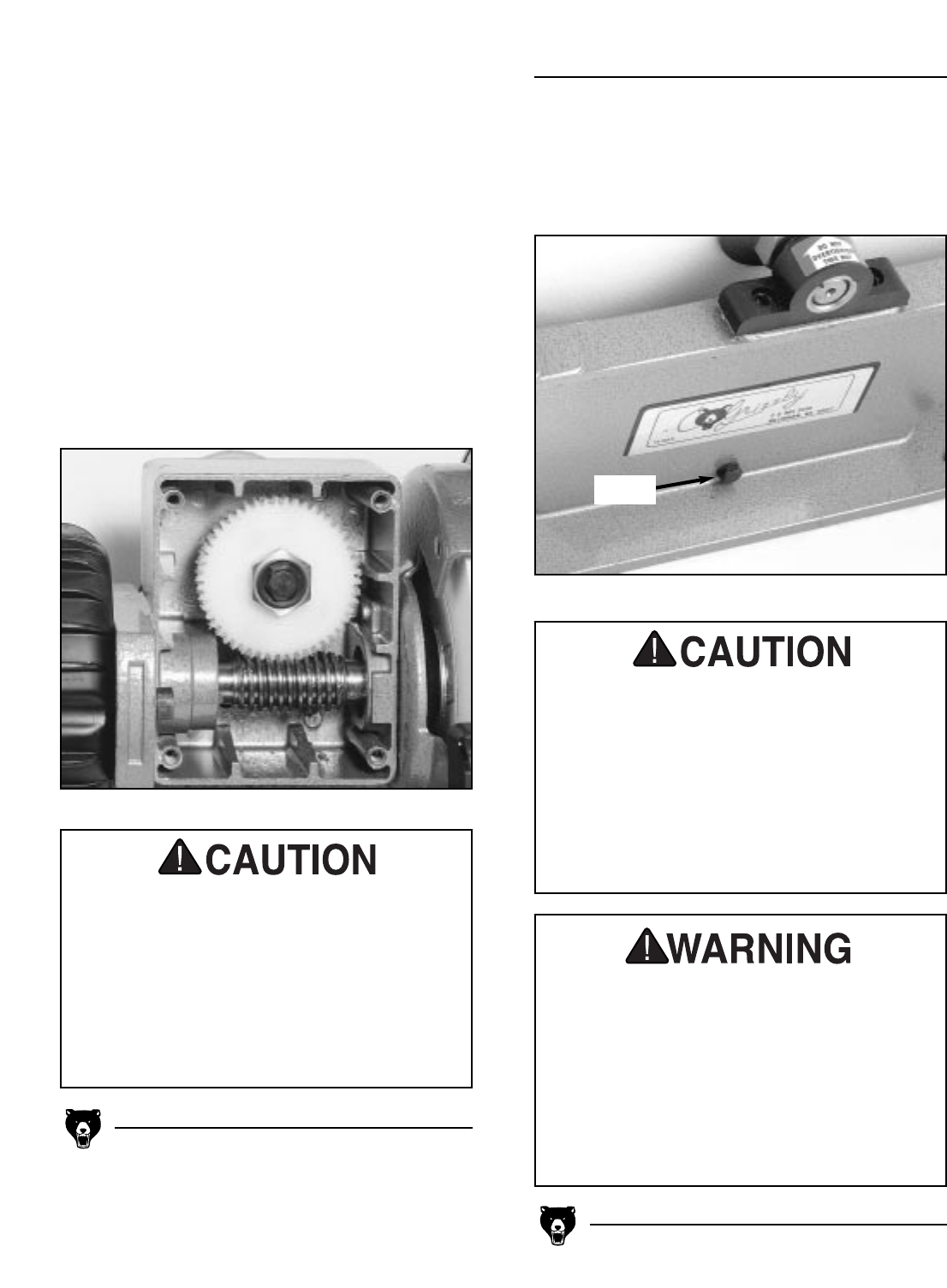

in the reservoir once a week to avoid clogging the

aluminum oxide wheel. A drain plug at the bottom

of the reservoir can be removed to flush out the

reservoir and remove sediment. Figure 8.

Figure 8. Drain plug on reservoir.

Drain

C. GEAR BOX

The gear box contains the worm-and-pinion gear

that transmits power to both the 4

1

/2" and 10"

wheels. The gears should be lubricated with a

light gear grease after every 300 hours of use.

Inspect the gears for wear or damage during

each lubrication. To lubricate:

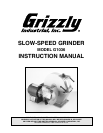

1. Remove gearbox cover. Figure 7.

2. Apply a light coating of grease to the gears.

3. Re-attach cover.

Figure 7. Gear Box cover removed.

The motor of the Slow-Speed Grinder oper-

ates at high speeds. DO NOT attempt to

inspect or lubricate the gears while the

machine is running. Turn off the machine

and disconnect it from its power source

before servicing. Failure to do so could

result in serious personal injury.

IX. MAINTENANCE (Continued)

DO NOT attempt to use the 10" grinding

wheel without filling the reservoir with

water. Overheating caused by lack of lubri-

cation could damage the grinding wheel, as

well as the tool or blade you are grinding.

Ensure that the reservoir is filled with clean

water. Sediment-filled water can clog the

wheel and lessen the grinder’s ability to

work effectively.

DO NOT allow the grinding wheel to stay

immersed in water for long periods of time

without running. The water can cause the

wheel to become waterlogged and unbal-

anced and may cause sections of the wheel

to break off when the wheel is started.

Always drain the reservoir when the grinder

will not be used. Serious personal injury

may occur.

D. WATER RESERVOIR

A constant supply of water is essential for opti-

mum 10" wheel performance. Change the water