G1066/G1066Z/G1079 Drum Sander

-27-

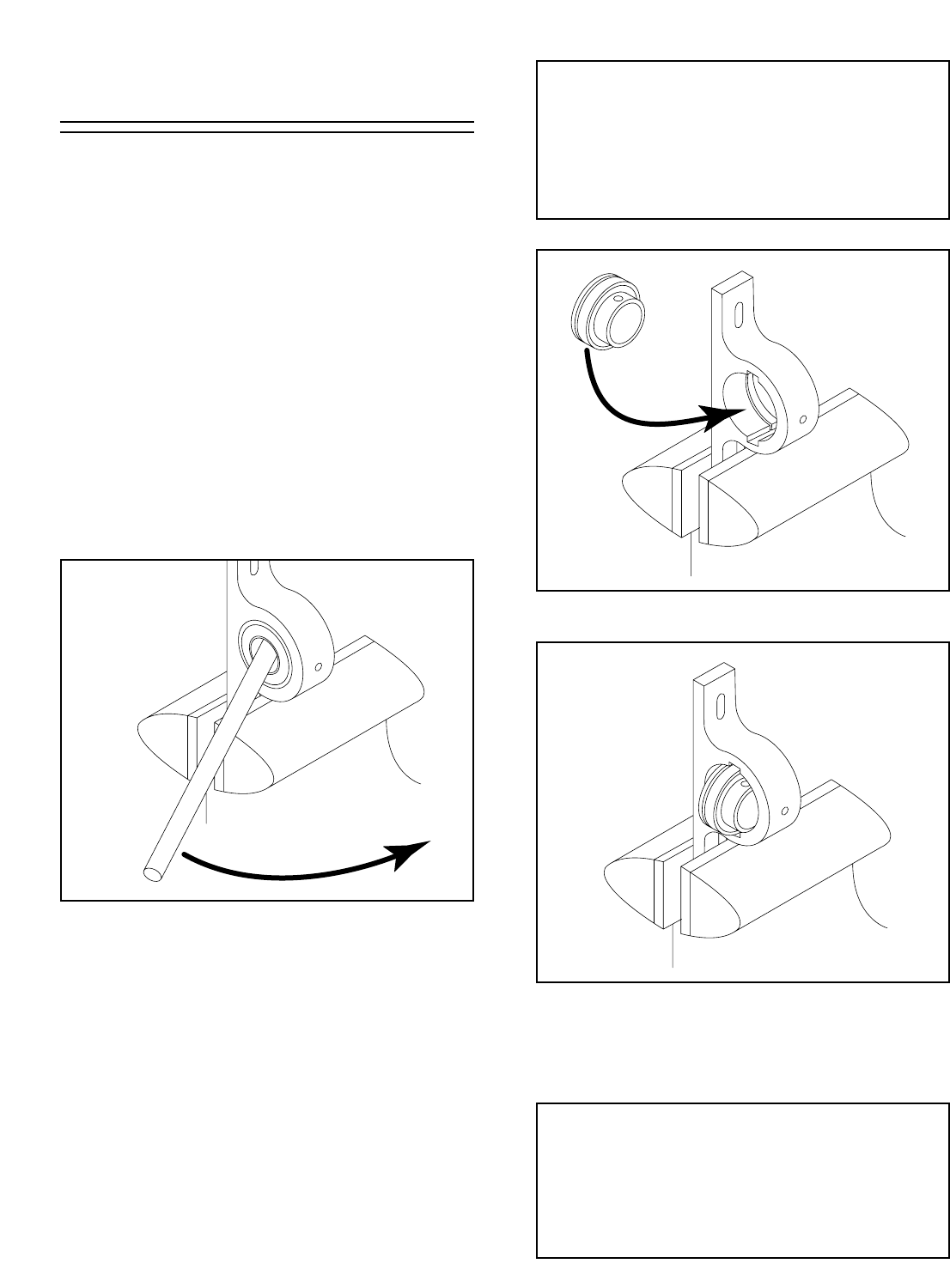

Bearing Replacement

Figure 18. Detaching bearing from housing.

6. Re-attach the sanding head cover before

operating the sander.

3. Once the old bearing is removed, clean the

bearing housing. Insert the new bearing into

the notches in the housing as shown in

Figure 19. Twist the bearing clockwise 90°

after it reaches into the housing as far as it

will go as shown in Figure 20.

4. Insert the screwdriver through the bearing,

as in step 2 and lever the bearing into its

proper position in the housing.

5. Press or tap the bearing and housing back

into place on the drum shaft. Re-adjust the

drum as necessary.

The tools necessary for this job are a large round

shaft screwdriver and a bench vise. Replace

bearing as follows:

1. Remove the roller housing from the drum

sander and clamp it tightly in a bench vise.

2. Insert the screwdriver into the center hole of

the bearing as shown in Figure 18. Lever the

bearing until it turns perpendicular to the

housing. Once the bearing is turned 90° from

the housing, it should slide free with little

effort. The housing is designed with notches

that allow the bearing to be inserted and

removed. It is important that you lever the

bearing so it turns in alignment to those

notches.

Figure 19. Matching bearing tab to notch.

Figure 20. Inserting bearing into housing.

NOTICE

Lubricate the bearings sparingly after about

two months of sander operation. The bear-

ing requires very little grease, so avoid the

temptation to over-lubricate.

NOTICE

Make sure, when installing the new bearing,

that the lubrication groove in the bearing

will match the groove and grease fitting in

the housing once it is in place.