G1183/1276 Combination Sander -19-

Bevel Sanding

When bevel sanding, be sure to re-position the

work table so it is at a maximum of

1

/16" away from

the disc or belt.

1. Hold workpiece against miter gauge to

keep piece square to the disc or belt.

2. Move workpiece against sanding surface

width to ensure even abrasion. Use even,

but firm, pressure.

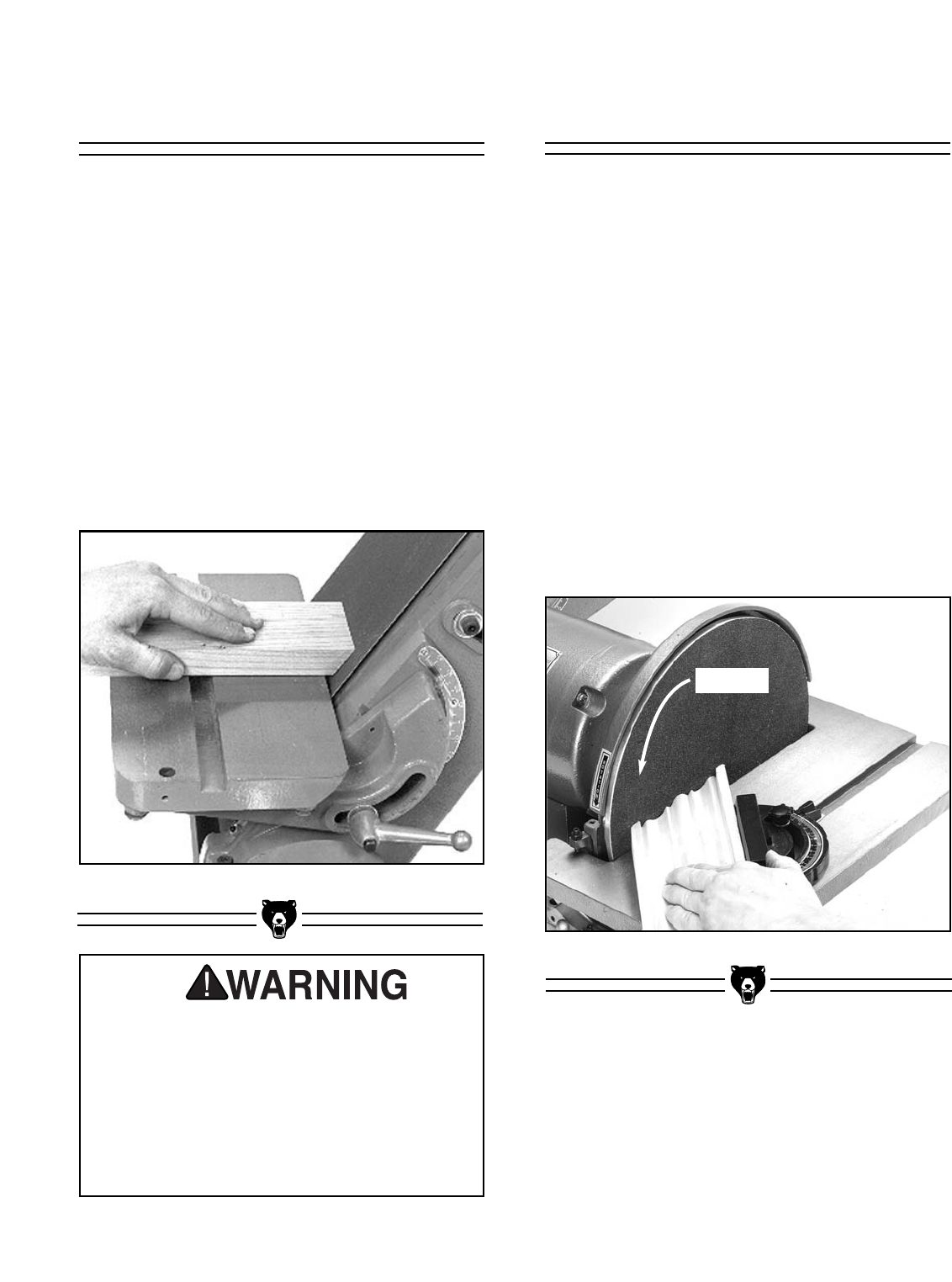

3. When using the belt arm for bevel sanding,

you will have greater control over your work

if you tilt the belt arm and maintain the table

at level. See Figure 19.

Figure 19. Bevel sanding.

DO NOT attempt to operate this machine

before completing the assembly and adjust-

ment instructions. Be sure that the switch is

off and the cord is disconnected from the

power source at all times until assembly

and adjustment are complete and you have

reviewed all safety guidelines. Serious

injury could occur.

Miter Sanding

The most efficient way to get a perfect miter is to

cut the workpiece slightly long and sand it to the

desired dimension. Miter sanding can be done on

either the belt or the disc.

1. Loosen the knob on the miter gauge and

adjust the angle to the desired point.

Tighten the knob.

2. Slide the miter gauge into its slot and use it

to hold your workpiece in position. The

miter gauge can be used in either direction

in the slot to achieve the proper relation of

the workpiece to the disc.

3. With light, but firm pressure, push the work-

piece slowly into the downspin side of the

rotating disc. See Figure 20.

Figure 20. Mitering with gauge reversed.

Rotation