-12-

G7211/7212 24" Bandsaw

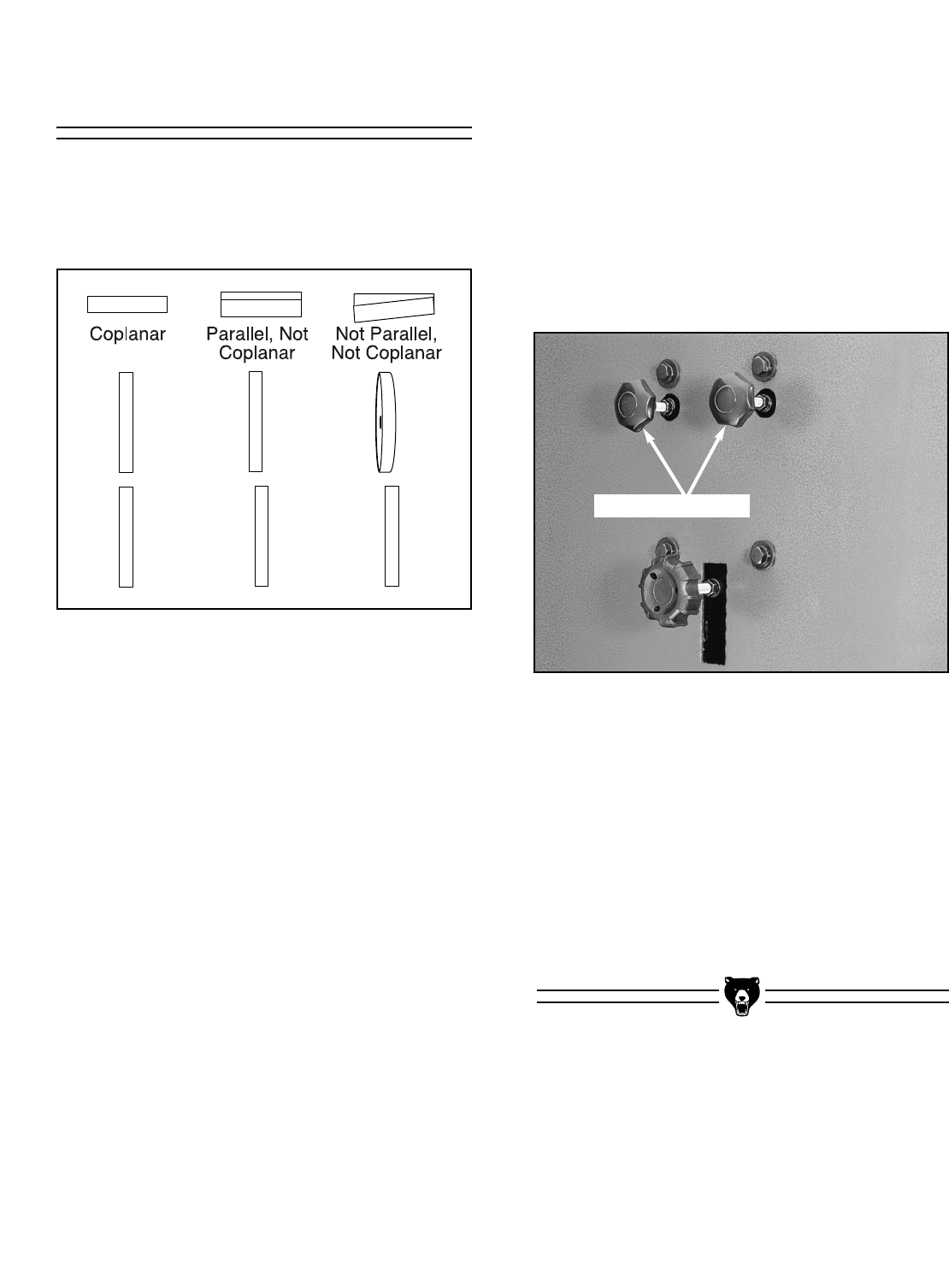

Figure 6. Wheel alignment adjusting knobs.

Adjusting Knobs

Figure 5. Wheel alignment conditions.

For proper operation of the bandsaw it is impor-

tant that the upper and lower wheels be aligned

so they are in the same plane. See Figure 5 to

understand the relationship between the wheels.

Wheel Alignment

The adjustment knobs on the upper wheel (See

Figure 6) can be used to correct for deviation in

parallelism between the two wheels. Although this

has been set at the factory, it is a good idea to

check it occasionally to assure proper operation

of your bandsaw. Loosen the check nuts and

adjust as necessary by turning one knob in and

the other knob about the same amount. Adjust in

small increments and check the measurement

between the wheels until the wheels are in align-

ment.

On the G7211/7212 it is not possible to lay a

straightedge across the two wheels to check

coplanarity and parallelism because of the

arrangement of the wheels in the cabinet. The

wheel relationship can be checked by clamping

two blocks of exactly the same size (must be at

least 2" high to extend beyond the cabinet) and

squareness to each wheel (use the large holes in

the wheels for the clamp), then use a straightedge

to check the wheel position. It will be necessary to

remove the fence and the table to perform this

check.

If the wheels are not coplanar, the bearing mount

on the lower wheel can be adjusted to move the

wheel position in or out, or the wheel can be

shimmed on its shaft. This is a major service pro-

cedure, however, and should be undertaken very

carefully. Normally the positioning of the wheels

will not change as long as the saw is properly

cared for and is not dropped or tipped onto its

back or side. Contact Customer Service for more

information on wheel alignment if you are experi-

encing difficulty.