G8994 Variable Speed Jig Saw

-8-

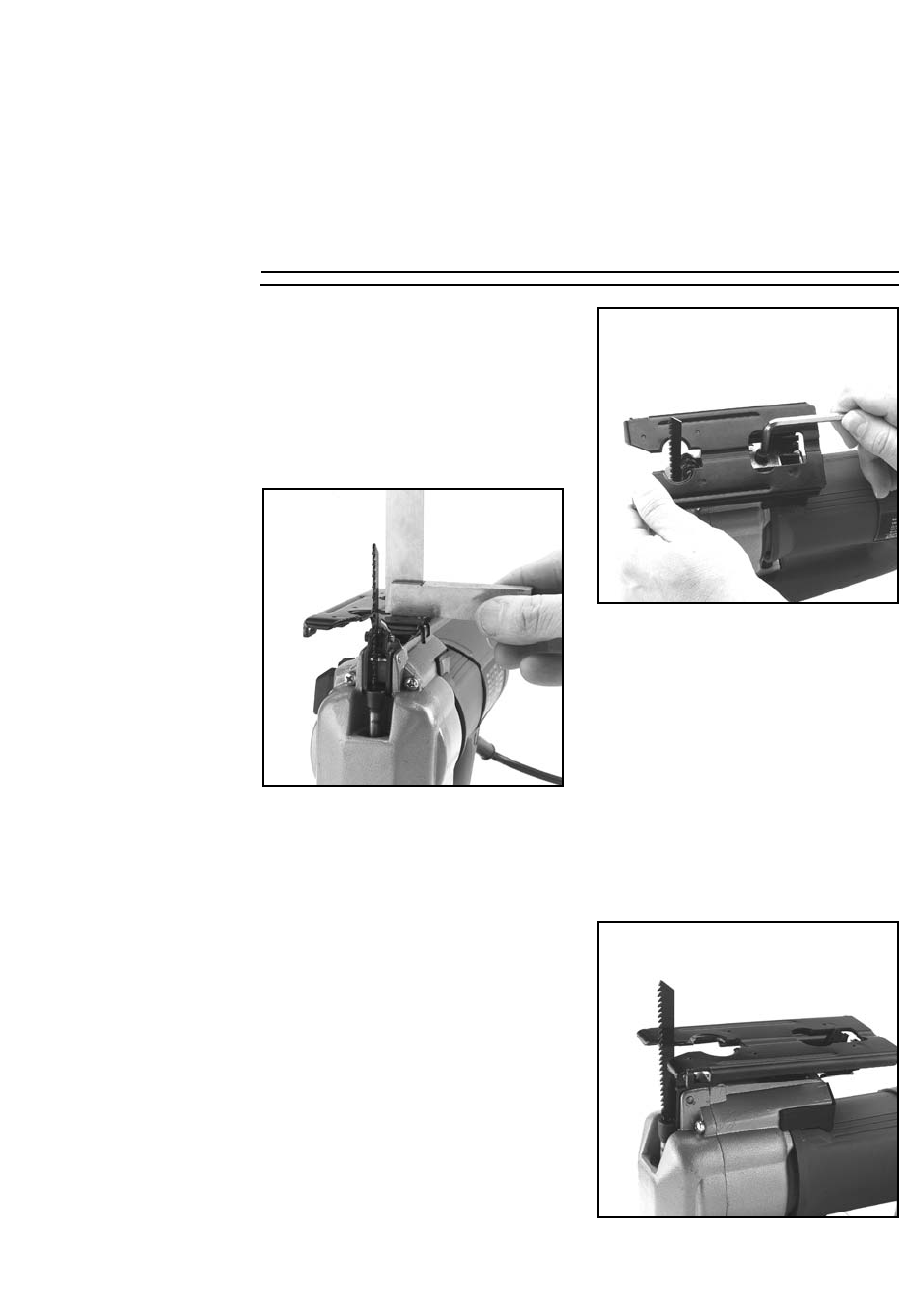

FOOTPLATE ADJUSTMENT

The footplate can be adjusted for cutting at

90˚ to the surface as well as any angle

from ±45˚. To be certain the footplate is

cutting at precisely 90˚, it is useful to check

the blade squareness to the footplate with

the use of a small machinist’s square. See

Figure 9.

Fig 9. Checking blade squareness.

Fig 10. Setting footplate for angle cuts.

Fig 11. Footplate positioned for flush cutting.

To adjust to another angle, use the sup-

plied Allen

®

Wrench to loosen the bolt hold-

ing the footplate. Slide the plate forward

slightly to disengage it from the notch, and

tilt it to the desired angle. At the 45˚ points

there are notches which position the plate.

By pushing the plate back when near 45˚,

the notches will lock the plate in position. If

an angle between 90˚ and 45˚ is desired,

set the angle and leave the plate in the for-

ward position, and tighten the bolt. See

Figure 10.

The footplate can also be set to accommo-

date flush cutting. This might be used

when it is desirable to cut right up to a wall

or other vertical surface. Remove the bolt

holding the footplate with the Allen

®

wrench. Slide the plate backward so the

mounting hole lines up with the rearmost

mounting hole. Reinstall and tighten the

bolt. The footplate’s front edge will be

slightly behind the leading edge of the

blade as shown in Figure 11.