-34- Ultimate Series Jointers

4. Sparingly oil the threads of the carbide cutter

Torx® screws with a light machine oil.

5. Adjust the compressor air pressure to 30 PSI.

Note—The low pressure (torque) setting will

reduce the chance of cross threading the

Torx® screw threads as well as seat the car-

bide cutters correctly.

6. Once all the Torx® screws have been seated,

turn the compressor air pressure to 85 PSI.

Further tighten the Torx® screws to their final

torque setting of 48-50 Inch-Pounds.

Removing the carbide cutters:

Torx® screws that are difficult to remove with the

air wrench can be removed with the supplied T-

handle. Carefully insert a Torx® bit into the hole

on the side of the “cheater bar.” This should allow

you enough leverage to loosen the Torx® screws.

Infeed Table Cam

Under each corner of the infeed table is an eccen-

tric that can be turned with a wrench—lifting or

lowering that corner of the table. A coordinated

adjustment of all four eccentrics allows the infeed

table surface to be adjusted perfectly level with

the outfeed table.

To adjust the infeed table:

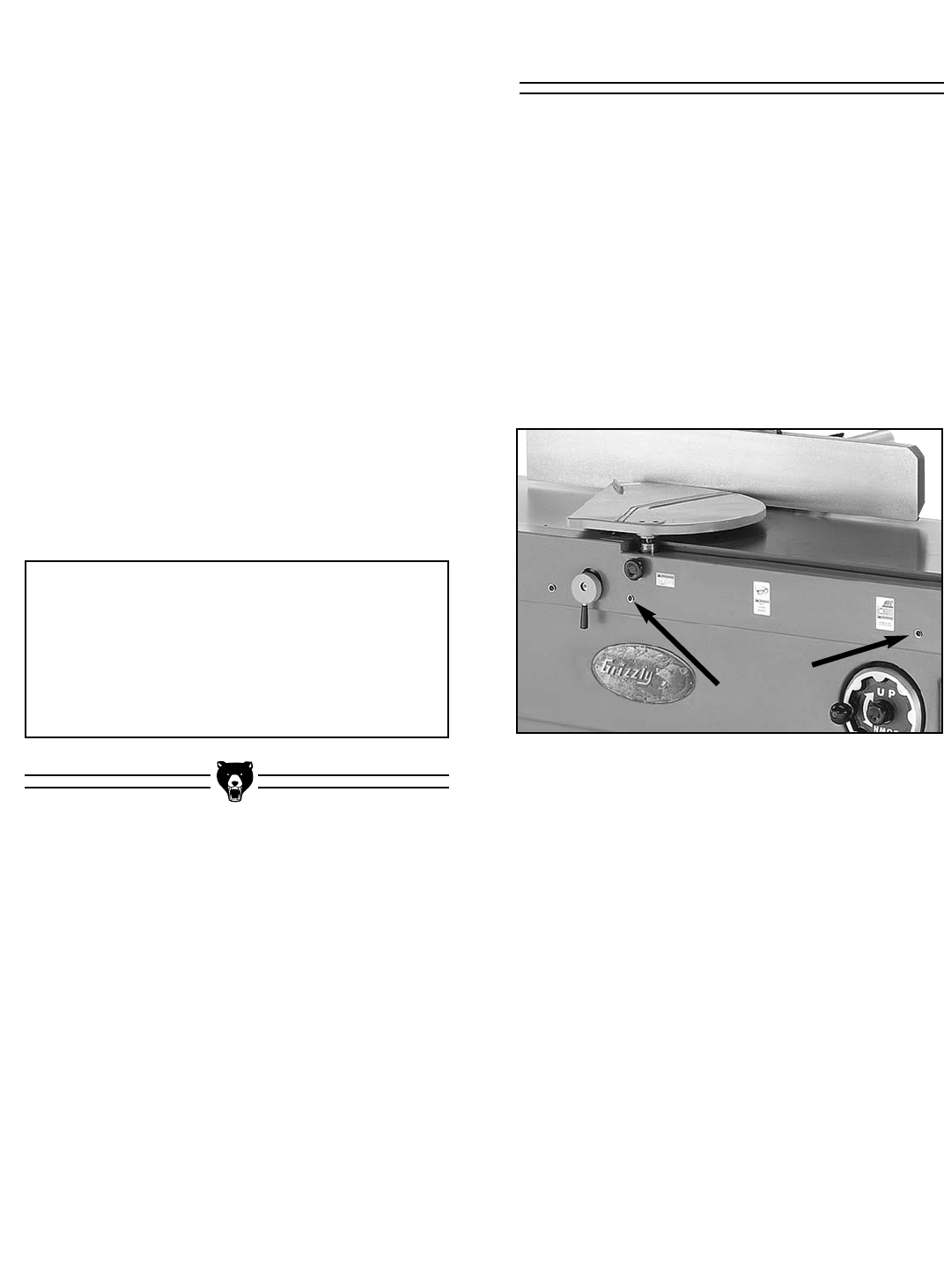

1. Remove the four hex bolts and flat washers

(Figure 38) that secure the front eccentric

cover to the jointer. Carefully remove the front

eccentric cover and set it aside.

Figure 38. Hex bolts and flat washers used to

secure the front eccentric cover

to the jointer base.

NOTICE

Remove sawdust from the heads of the

Torx® screws before attempting to remove

them from the cutterhead. The head of the

Torx® screws could become stripped if this

is not done.