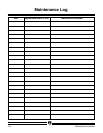

Ultimate Series Jointers -29-

Most of the ball bearings are permanently sealed

and lubricated so they will require no attention

until they need to be replaced. The following loca-

tions should be lubricated after approximately 80

hours of continuous use.

Cutterhead

The cutterhead has two bearings that require

grease. There are white stickers with arrows

pointing to their general location. There are two

grease fittings—one located at each end of the

cutterhead, on the top of the cutterhead axle col-

lars. The grease fitting on the front side of the

jointer is located in a small hole cut into the top of

the front base housing. The grease fitting on the

back side of the machine is located on the top of

the jointer base, just under the bottom edge of the

fence.

Handwheels

Each handwheel is lubricated via an oil cup locat-

ed just behind the handwheel body, on the axle

collar. Remove the handwheel lock knob and

slide the handwheel off the axle. This will reveal

the oil cup. Apply a small amount of light machine

oil.

Table Elevation Mechanism

The table elevation screw and gear mechanism

for each handwheel can be accessed by remov-

ing the left and right rear base housings. Apply a

generous amount of grease to the elevation

screws and gears.

Lubrication

Using sharp knives is one of the most important

factors involved with the operation of the jointer.

A good maintenance procedure is to hone the

knives to keep them in top shape. A knife hone

will polish and finely sharpen jointer knives quick-

ly and easily without removing them.

For damaged or extra dull knives, have them

resharpened by a professional grinder. To avoid

downtime from resharpening, we recommend

having an extra set of knives on hand.

The carbide cutters are typically rotated at the

same time when they become dull; however, the

cutters can also be rotated individually when one

becomes nicked or damaged. Refer to Section 8:

Service Adjustments for instructions on rotating or

replacing the carbide cutters.

Knives

(Model G9953 Only)

Carbide Cutters

(Models G9953ZX, G9953ZXF and G4815)