H4380 Buffer -11-

Buffing Tips

Here are some quick tips for getting the most out

of your buffer:

• Thoroughly clean all parts that you are plan-

ning to buff. Any kind of dirt, oil, rust, paint or

other film must be removed either chemically

or sprayed off with water. Make sure to dry off

parts with a rag after cleaning.

• Apply buffing compounds in small amounts at

a time. While the machine is running, press

the compound on the wheel for a couple of

seconds. Avoid using too much compound.

• Put your workpiece under the wheel when

you are loading the compound on the buffing

wheel. This way, you will catch any com-

pound that would normally be wasted on the

floor.

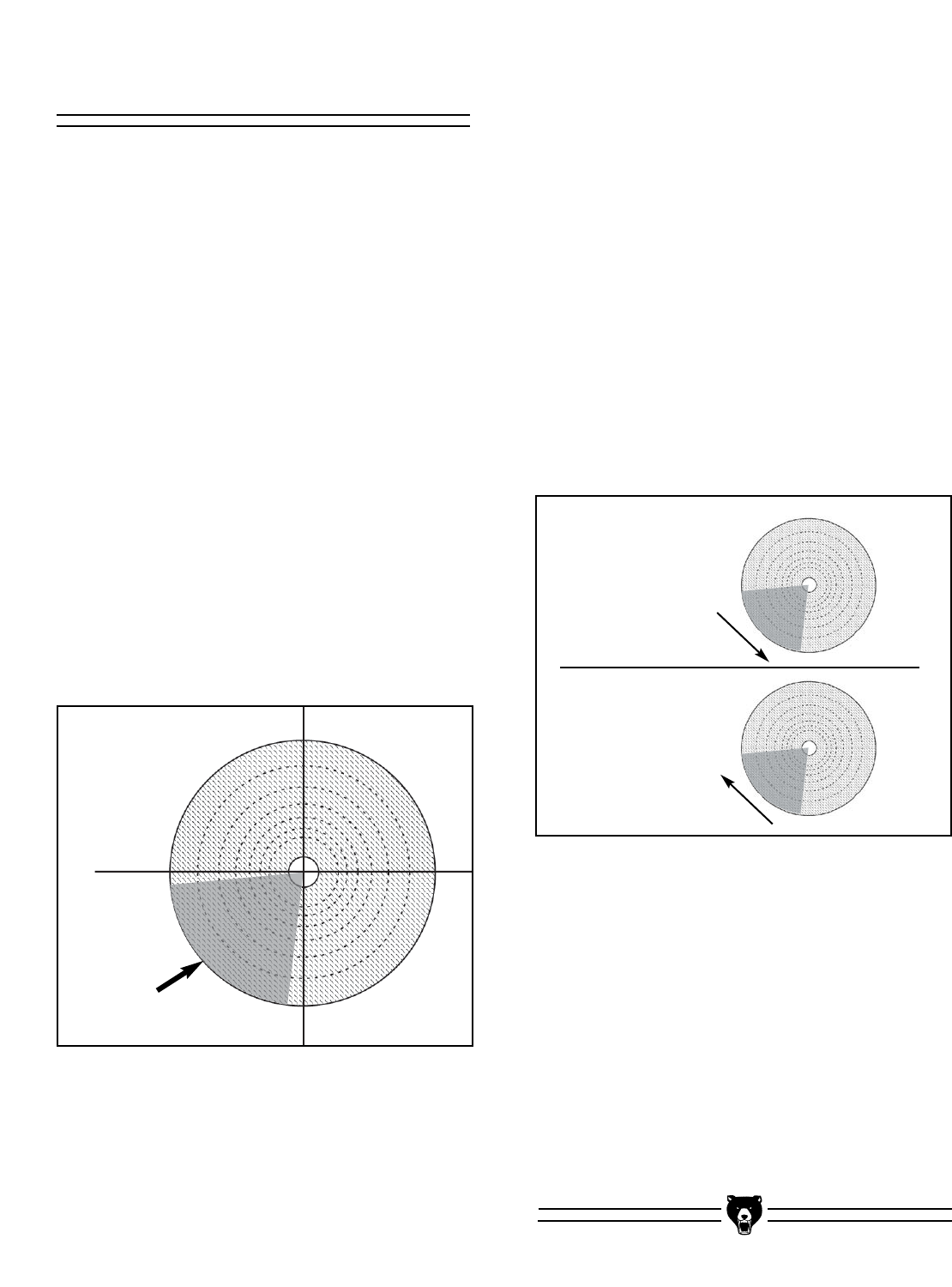

• Only use the area grayed-out in Figure 4 to

do the actual buffing. Contacting the work-

piece on areas outside of the grayed out area

may flip the workpiece out of your hands.

• Hold the workpiece tightly at all times while

buffing. One hand near the contact point will

give you better control.

• Keep buffing wheels raked out before each

use and when buildup gets heavy during use.

“Raking” means to clean the buffing wheels

with a wheel rake to remove buildup com-

pounds and metal particles. An old rough-cut

saw blade or a large hacksaw blade will also

work as an alternative to a wheel rake.

ALWAYS use light pressure when raking

wheels!

• Do not mix two different compounds on the

same wheel. For best results, use a separate

wheel for each compound.

• Use an upward stroke with heavy to moder-

ate pressure for cutting. Use a downward

stroke with light to pressure for polishing. See

Figure 5.

Downward

to Polish

Upward

to Cut

Figure 5. Cutting and Polishing strokes.

•Wear safety equipment when buffing. If the

buffer forces the workpiece out of your hand,

be prepared for it to come flying at you! Wear

safety glasses and a heavy leather apron.

Also, wear a dust mask to protect your lungs

from microscopic particulate that will be flying

off the wheel.

Remember, there is no substitute for experience.

Learning how to hold the workpiece, how much

pressure to apply, how to move the workpiece

against the wheel and how much compound to

use will require some trial-and-error.

Front

Figure 4. Illustrated from a side profile, shows

the only portion of the wheel that should be used

during buffing.

Make

Contact

Here