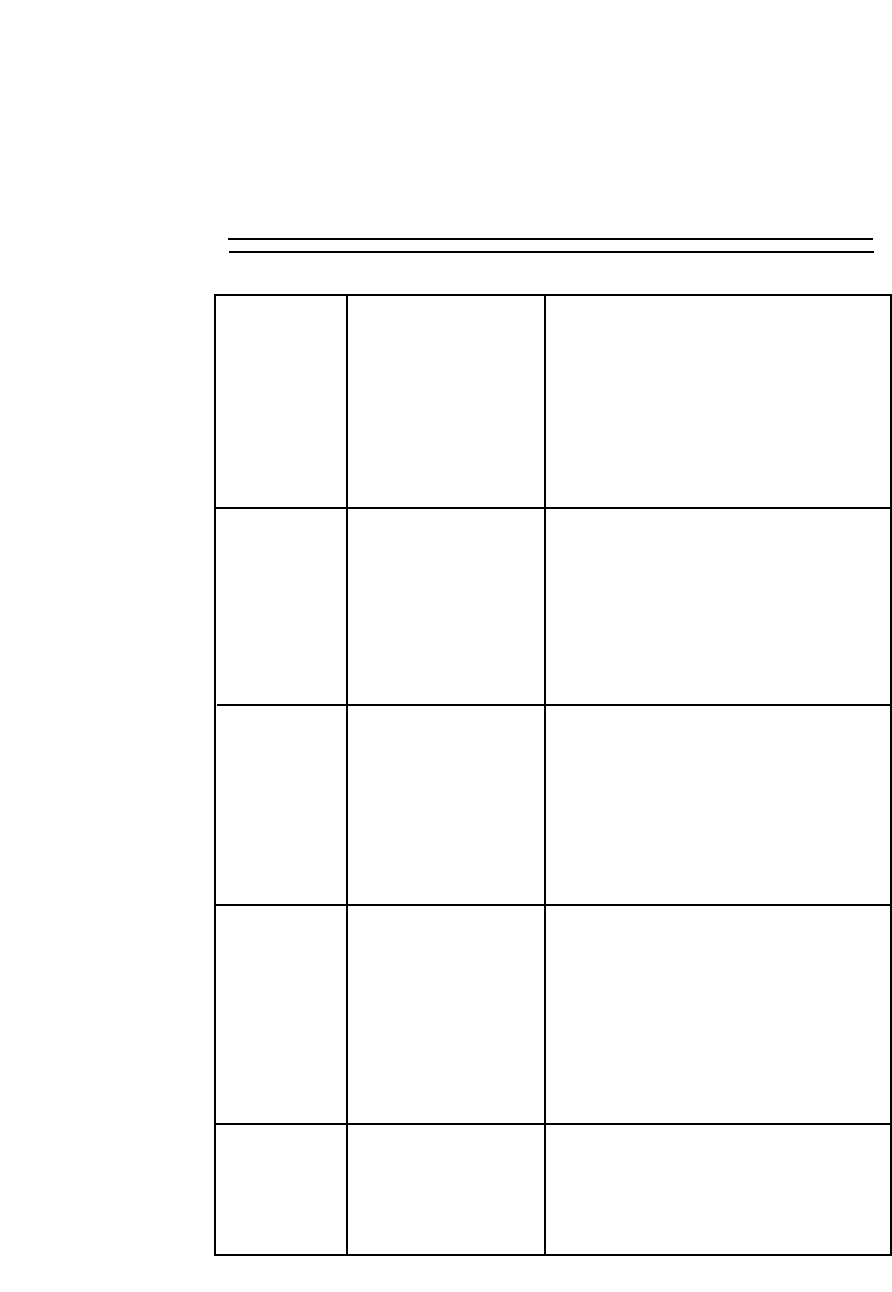

-16- H4519 3 HP Air Compressor

TROUBLESHOOTING

Pump motor

will not start.

Pump motor

starts; but

fuses blow or

circuit break-

ers trip.

Low pressure

at the tool.

Low pressure

at the tanks.

Compressor

knocking.

1. Check power line for proper voltage.

2. Inspect all lead connections on motor,

switch and cord for loose or open connec-

tions.

3. Motor will not start if tank pressure is too

high.

4. Thermal overload switch has tripped, wait

for motor to cool, then reset switch by

pressing red button.

1. Inspect cord or plug for damaged insula-

tion and shorted wires.

2. Inspect all connections on motor for loose

or shorted terminals or worn insulation.

3. Install correct fuses or circuit breakers.

1. Check air hoses and all connections for

leaks.

2. Check pressure in line with known good

gauge.

3. Adjust pressure regulator, if no improve-

ment inspect regulator for leaks or

replacement.

4. Install a shorter hose.

1. Check air tanks, pipes and all connections

for leaks.

2. Close drain valve.

3. Replace safety valve.

4. Inspect and clean air filter.

5. Check gaskets on cylinder head assem-

bly, repair or replace as needed.

6. Inspect and replace pump piston rings.

1. Check oil level and add oil.

2. Inspect and clean air filter.

3. Inspect and repair piston and connecting

rod.

PROBLEM

CAUSE

ACTION

1. Low voltage.

2. Open circuit in

motor, switch or

cord.

3. Tank already pres-

surized.

4. Thermal overload

switch.

1. Short circuit in line

cord or plug.

2. Short circuit in motor

or loose connec-

tions.

3. Incorrect fuses or

circuit breakers in

power line.

1. Air leaks in flexible

hoses.

2. Pressure gauge bad.

3. Pressure regulator

bad.

4. Hose is too long.

1. Air leaks in tanks or

delivery pipes.

2. Drain valve open.

3. Safety valve releas-

ing below 125 PSI.

4. Air filter clogged.

5. Gaskets leaking.

6. Worn rings.

1. Improper oil level.

2. Air filter clogged.

3. Piston assembly

loose.