H6146 34° Clipped Head Framing Nailer

-9-

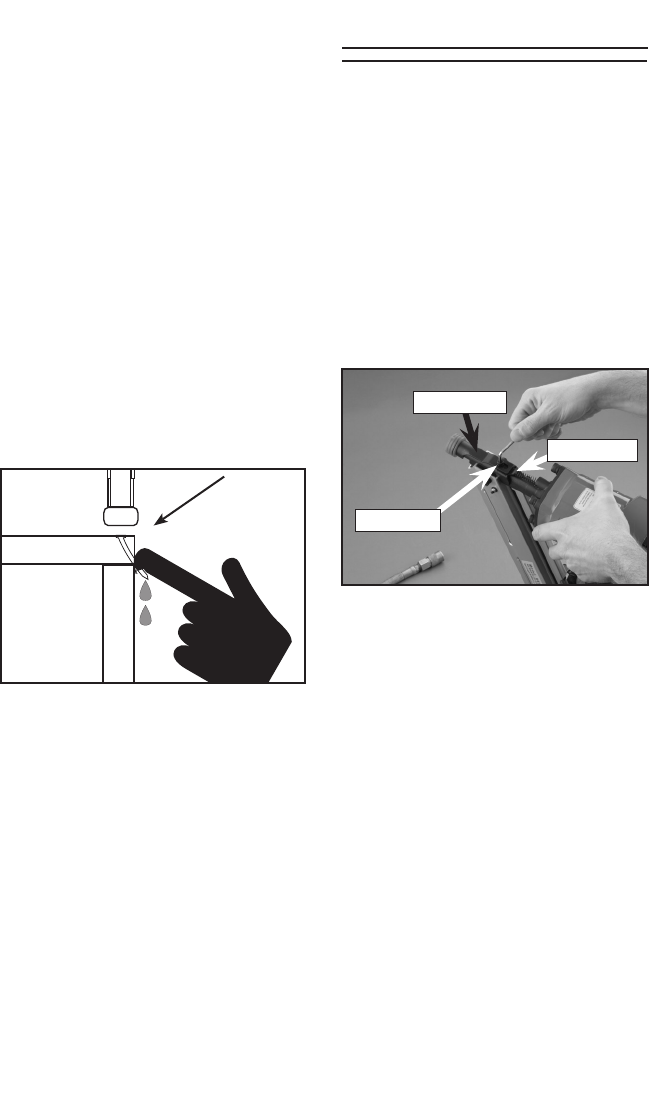

Figure 6. Loosening cap screw for depth

adjustment.

The nose of the gun houses a depth adjust-

ment mechanism for setting the nail depth.

To adjust the dep

th:

1. DISCONNECT NAILER FROM THE

AIR SUPPLY!

2. If the nail is driven too far into the

workpiece, loosen the cap screw on

the safety nose with a 4mm wrench, as

shown in Figure 6.

5. Pull the trigger. If the nail drove into the

wood far enough, continue with your

intended operations. If the nail either

went too far or not far enough, then go

to the Adjusting Depth section on this

page.

3. Pull the trigger and depress the safety

yoke mechanism on your workpiece.

4. Before pressing the trigger, make

sure your free hand and other body

parts are positioned out of the way

of a potential path of a nail in case of

deflection.

Deflection is caused when grain

irregularities, knots or foreign objects

inside the wood cause the nail to

change its path, resulting in the

nail puncturing the surface of the

workpiece, as shown in Figure 5.

Besides damaging your workpiece,

deflection can cause injury if your free

hand is securing the workpiece in the

location that the nail deflects.

Figure 5. Example of nail deflection.

Adjusting Depth

3. Slide the safety nose (Figure 6) toward

the nailer body to drive nails deeper,

and away from the body to drive nails

less deep.

4. Tighten the safety nose cap screw

each time after making adjustments.

5. Connect to the air.

6. Pull the trigger and depress the safety

yoke mechanism on your workpiece to

test the depth adjustment.

Safety Yoke

Safety Nose

Cap Screw