Model H6155 Rotary Mini Grinder -7-

Use low RPM settings when work-

ing with plastics or other materi

-

als with low melting points. Melted

plastics can liquefy, be thrown into

the air, and stick to the operator,

causing serious personal injury.

High RPM Uses

High RPM's are best for general carving,

cutting, routing, and grinding. The grinder

removes material quicker at higher RPM's.

Low RPM Uses

Low RPM's are best for grinding and cut-

ting materials that have low melting points.

Plastics in particular often melt from the

heat generated by high speed bits. Low

RPM's are also best for polishing and buff-

ing with the felt accessories included.

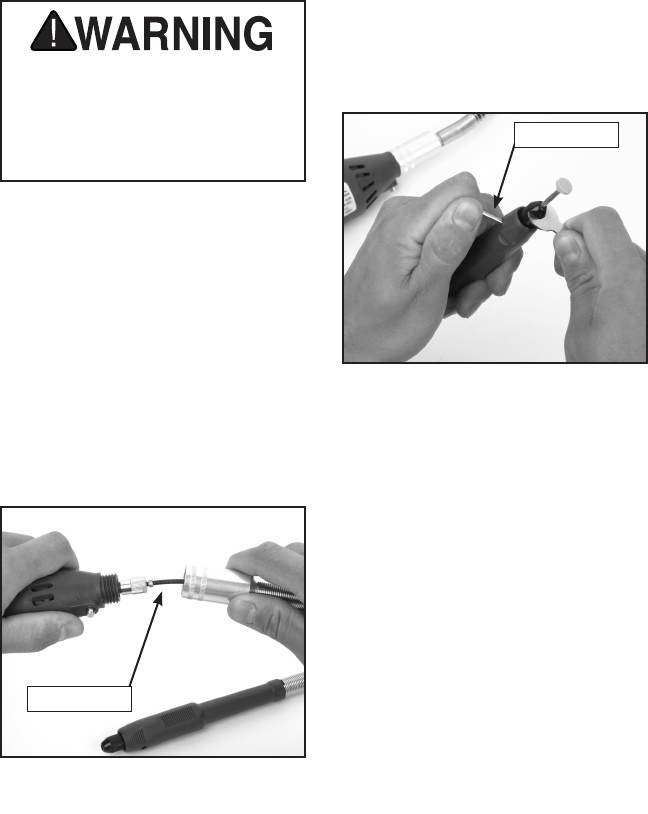

Installing the Flex Shaft

The flex shaft allows the user to get into

tight spaces and is easier to control; more

like a pencil. DO NOT operate the flex

shaft with sharp bends.

To install the flex shaft:

1. Unplug the tool from power!

2. Loosen the collet nut, and remove the

collet shield as shown in Figure 3.

3. Slide the inner spindle (Figure 3) par-

tially out of the flex shaft.

4. Insert the inner spindle into the collet

and tighten.

5. Slide the flex shaft up the inner spindle

and thread it onto the mini grinder in

place of the collet shield.

6. Insert a tool bit into the collet of the flex

shaft.

7. Insert the shaft of a tool bit into the

hole shown in Figure 4 and tighten the

collet. Note: Hold the flex shaft firmly

when starting the rotary mini grinder.

Figure 3. Flex shaft components.

Figure 4. Tightening the flex shaft collet.

Installing the Flashlight Base

The flashlight base will give you the extra

light that you need in low light situations.

To install the flashlight base:

1. Unplug the tool from power!

2. Remove the collet shield.

3. Screw the flashlight base onto the mini

grinder in place of the collet shield.

4. Turn the flashlight base ON/OFF with

the small switch on the face of the

flashlight base.

Inner Spindle

Tool Bit Shaft