H8154 AC/DC Stick/TIG Welder

-11-

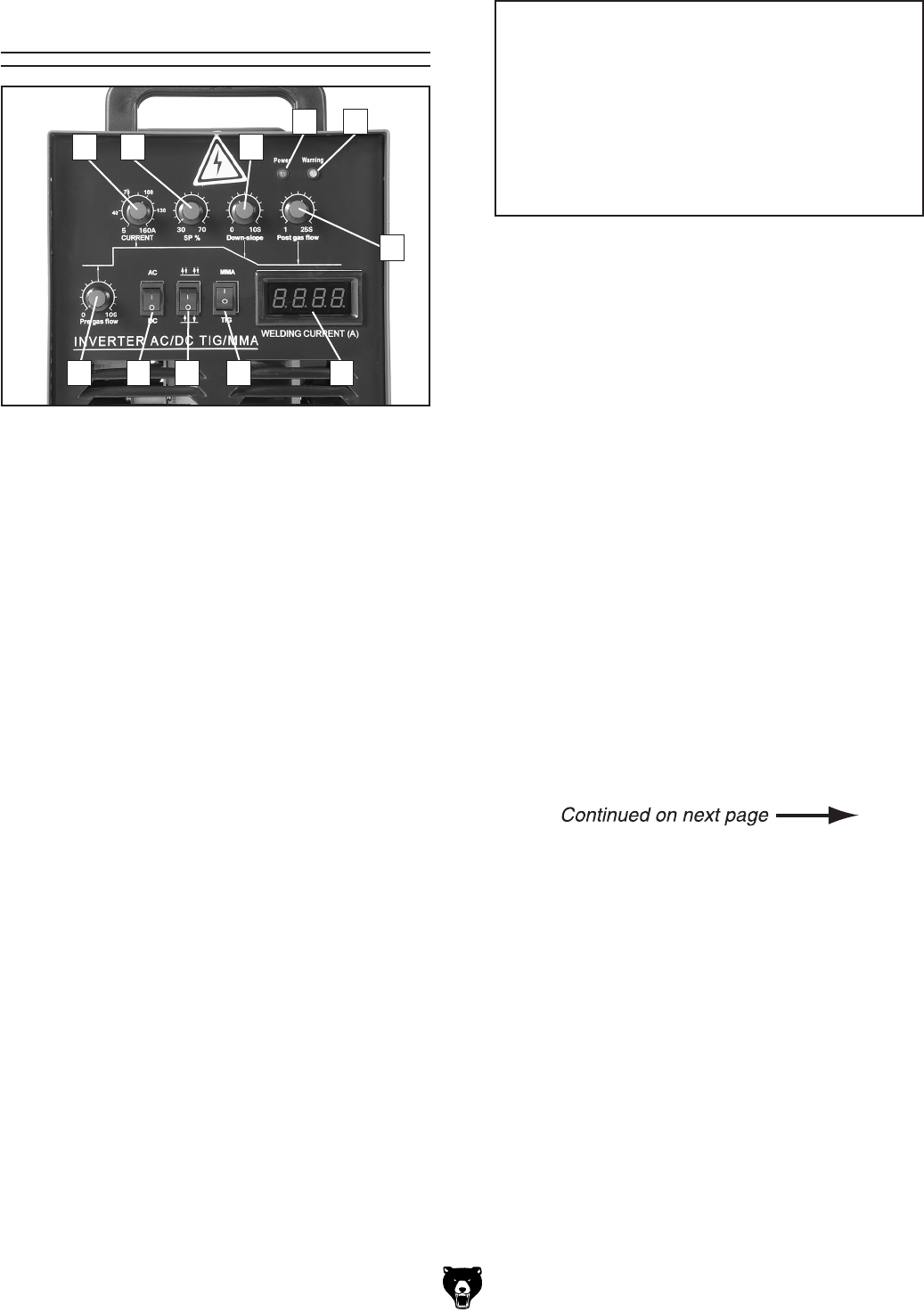

Welder Controls

NOTICE

After completing the welding operation,

keep the power to the welder

ON for a

period of time to let the welder fan cool

the welder down. To avoid damage to

your

welder, never shut the power

OFF before

the welder enclosure is completely cool to

the touch.

A. Output Current Dial: Adjust this control for

the correct welding output current.

—AC/DC Stick Welding ....................

5–130A

—AC TIG Welding ..........................

20–160A

—DC TIG Welding ...........................

5–160A

B. Square Wave Percentage: Use this dial to

adjust the deposition and penetration of the

AC TIG arc. The dial is incremented in per

-

centage of the positive square wave cycle.

For example, when the dial is set at 60%,

40% of each current cycle is negative and

60% is positive.

C. Downslope Current Dial: Use this dial to

control the amount of time (0–10 seconds) the

welding current decreases from the selected

output current to

OFF.

D. Power Light: This will light when the power

is turned

ON.

E. Warning Light:

—Not Lit: The welder is ready for use.

—Yellow: When the duty cycle has been

exceeded, the internal thermostat will dis

-

able the welding circuit until the fan has

sufficiently cooled the welder.

—Green: Output current is too high or the

welder has failed.

—Red: Input current is incorrect.

F. Post-Flow Time Dial: This knob will control

the amount of time (0–25 seconds) gas will

flow through the TIG torch after the welding

arc is shut off.

G. Welding Current: This LED readout shows

the welding output current in amperes.

H. Stick/TIG Selector: Use this switch to select

stick or TIG welding.

Figure 7. Model H8154 controls.

A B C

D E

F

GHK IJ