Model H8253 Air Belt Sander -9-

Keeping the sander clean is vital to its

operation and leads to longer tool life.

After every use, clean and inspect the

sander.

• Wipe the housing with a dry cloth, or

blow off the dust and debris with com-

pressed air.

• Check for damage to tooling, hoses,

housing or other accessories.

Do not allow dust, chips, sand, etc. into

the air connectors or into the body of the

sander air motor; this may result in leaks

and damage to the sander and the air

couplings.

Always disconnect air from sander

whenever servicing! During mainte-

nance, a sander connected to air may

start accidentally, causing personal

injury!

MAINTENANCE

Cleaning Lubrication

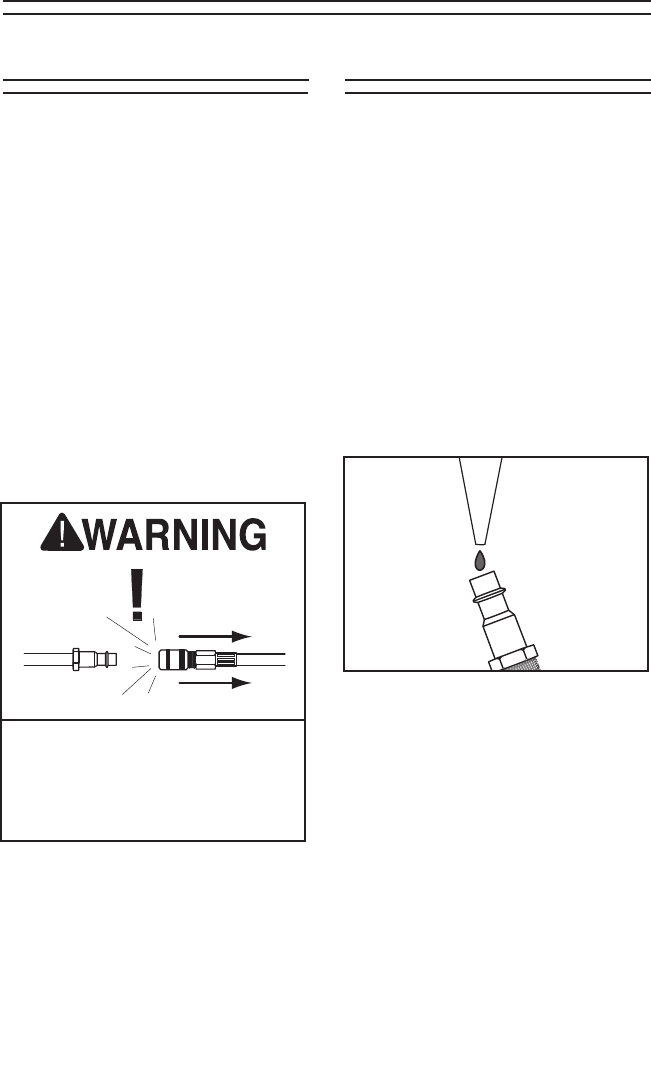

The air sander MUST have 2-6 drops of

oil dropped directly into the air inlet before

and after each use and before storage.

After oiling, remove the sanding belt, then

run the sander to purge excess oil. Wipe

the tool down with a rag, re-install the

sanding belt, then begin sanding.

Another option to manual oiling would be

to install a lubricator in your air compressor

line. If your air compressor line already has

a lubricator, then regular lubrication of your

sander will not be necessary. Just make

sure there is always oil in the lubricator.

Figure 14. Lubricating sander via air inlet.