G0536 Scroll Saw -15-

A typical scroll saw blade will wear out in

1

⁄2 to 2

hours, depending on the material cut. Blades

become dull quicker when cutting thick material,

plywood, laminates, hardwoods and metal.

To change the blade:

1. Disconnect the machine from the power

source

2. Remove the throat plate and the lower arm

guard shown in Figure 8.

3. Loosen the blade tension adjustment knob.

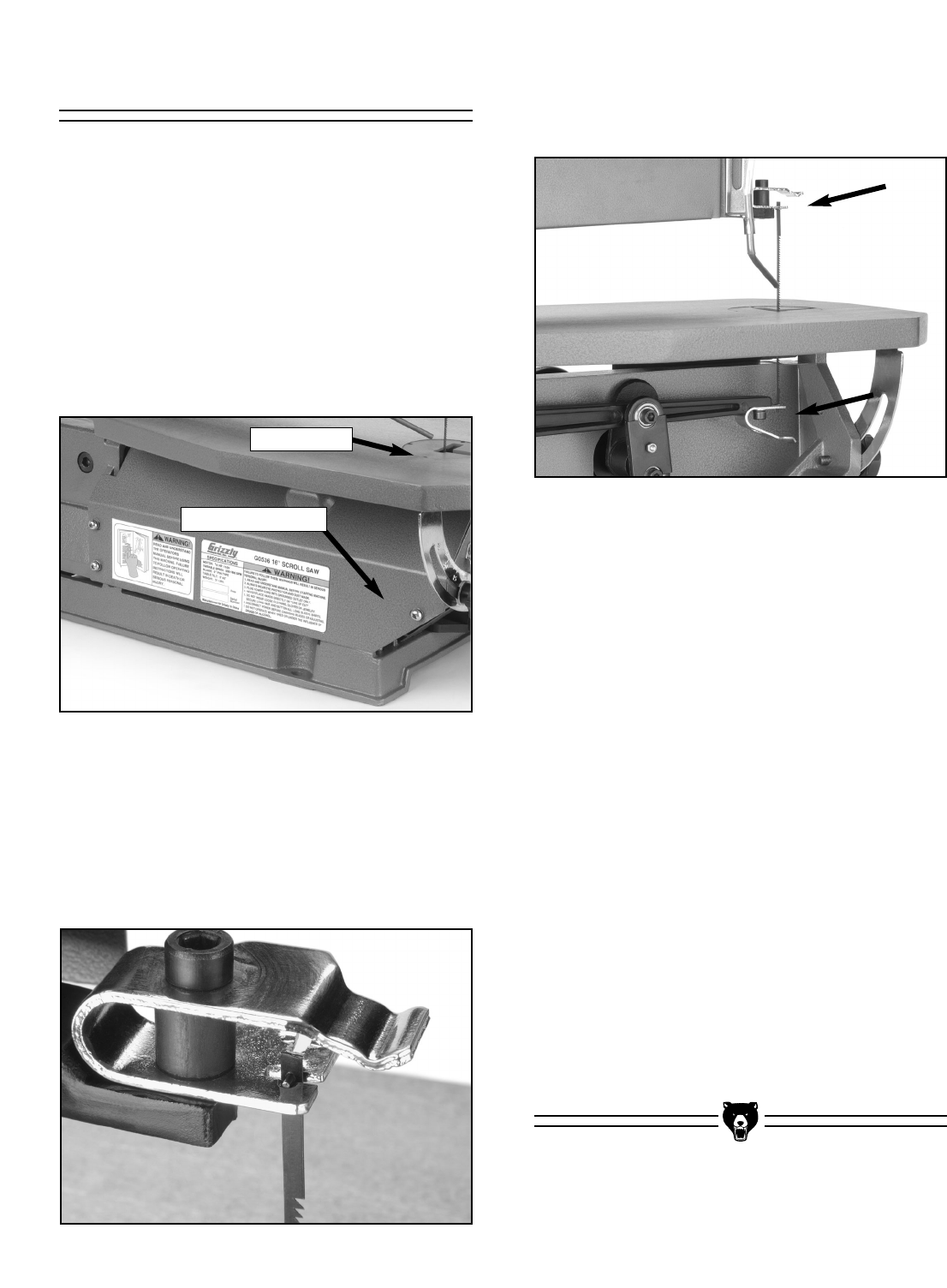

4. Push down on the upper blade holder shown

in Figure 9, pull the upper end of blade out

of the holder, push down on the blade to free

the lower end of the blade, and pull the blade

up to remove.

Figure 8. Arm guard screws and throat plate.

Throat Plate

Lower Arm Guard

Figure 9. Upper blade holder.

5. Feed the blade through the table and hook it

into the lower blade holder as shown in

Figure 10. The teeth should face forward

and down.

Figure 10. Blade attached to both holders.

(Guard removed for clarity)

6. Push down on the upper blade holder and

slide the upper end of the blade into the hold-

er. Make sure that the pins are seated into

the grooves in both holders.

7. Increase the tension on the blade until the

blade gives a musical sound when plucked.

Note—Determining correct blade tension is

subjective and is learned through experi-

ence. If the blade is not tensioned enough

the blade will drift off the layout line when

cutting. The scroll saw will also have exces-

sive noise and vibration. If the blade is too

tight the blade could break, causing serious

injury. Blades that are tensioned correctly

will last longer and be less likely to break.

8. Replace the lower arm guard and the throat

plate, and lower the blade guard into posi-

tion.

Note—The blades can also be installed with

the teeth pointing sideways to accommodate

long workpieces.

Changing Blades