-16-

G0536 Scroll Saw

Miter gauges and fences are not effective on

scroll saws because most scroll saw blades are

narrow and tend to follow the grain of the wood.

Freehand cutting allows the operator to compen-

sate for blade drift.

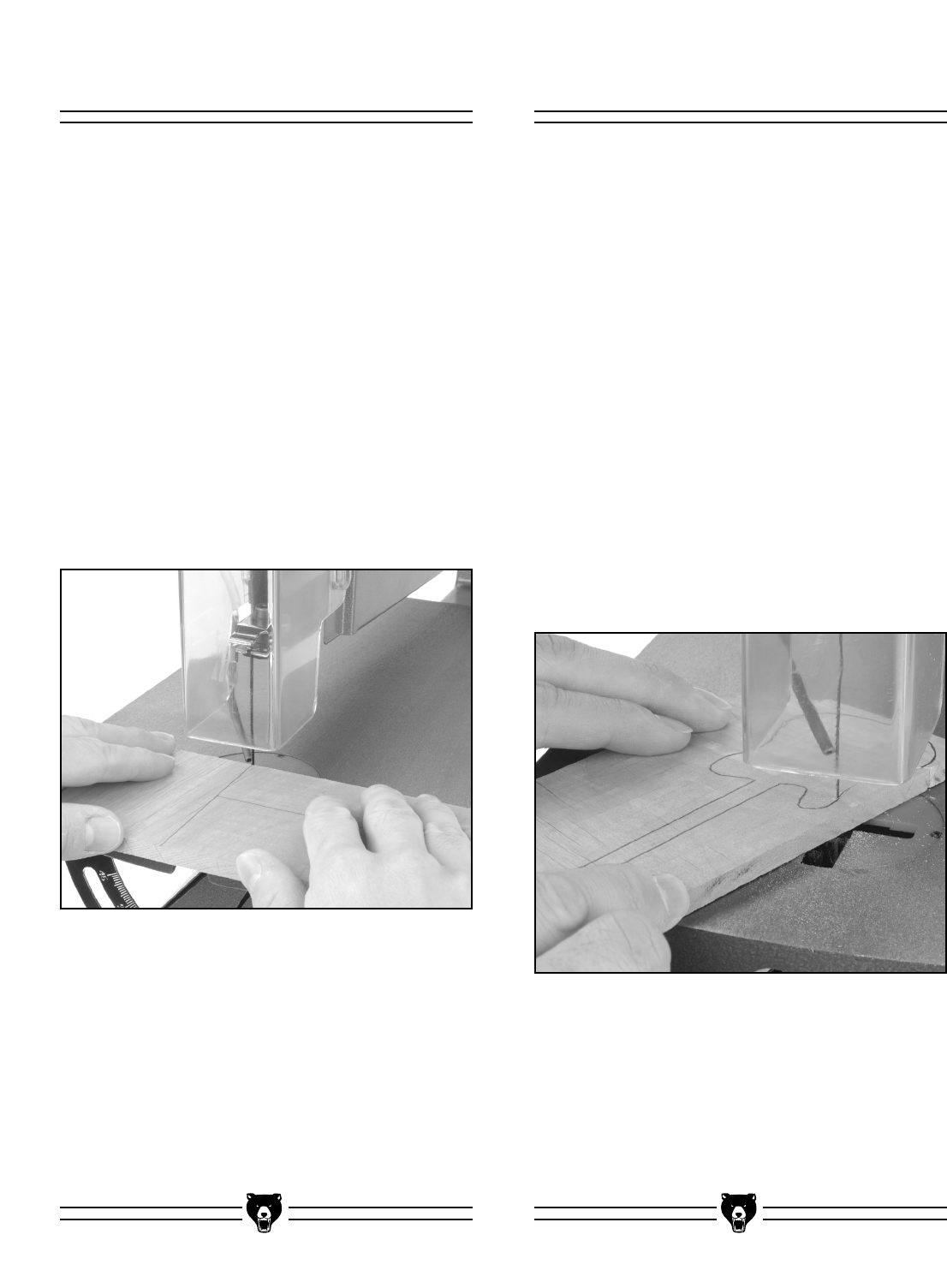

To make a straight cut:

1. Draw a straight line on your workpiece.

2. Turn the power ON and allow the motor to

reach full speed.

3. Feed the workpiece slowly and steadily into

the blade, keeping your hands to either side

of the cutting line while pushing down. Make

sure the blade is cutting on the waste side of

the line (Figure 11).

Figure 11. Straight cut.

When cutting curves, preplan your cut and leave

tight inside curves for a second pass to minimiz-

ing backing out. Cut sharp outside curves by cut-

ting past the curve and looping around to cut from

a different angle.

To make a curved cut:

1. Draw a pattern on your workpiece.

2. Choose a blade size based on the tightest

curve in the workpiece. Smaller blades can

cut tighter curves.

3. Rough cut the board down to a workable

size.

4. Feed the workpiece into the blade with a

slow and even pressure. Use your fingers to

hold it down and use your thumbs to steer as

shown in Figure 12.

Figure 12. Making a curved cut.

4. Scroll saw blades will have a tendency to

drift. Compensate by adjusting the feed

direction.

Note—The variation of hard and soft grain in

wood will cause the scroll saw blade to

deflect. If you are approaching hard grain at

an angle, the feed rate must be slowed and

pressure should be applied toward the side

with the hard grain.

Note—When approaching a tight radius,

slow down your feed rate, but don’t stop.

Give the teeth time to make the cut. Forcing

the workpiece through the curve will cause

the blade to twist or break. If your cut pro-

duces waste in the curve’s interior, turn the

power off and wait until all motion stops

before removing the waste.

Curved CutsStraight Cuts