A CAUTION

This equipment is compatible with most water

based materials. See the wetted parts in the Tech-

nical Data section and your fluid and solvent

manufacturer’s compatibility information.

Do not use catalyzed materials in heated applica-

tions.

I.

Preparing the Operator

All persons who operate the system should be trained

in the safe, efficient operation of all system compo-

nents as well as the proper handling of the chemical

coating. At a minimum, all operators should thoroughly

read the safety, installation, and operation sections of

this manual and the component manuals.

II.

Preparing the Site

1.

Use at least a 5 HP (3.7 Kw) air compressor for

efficient operation.

2.

Clear obstacles and debris that could cause an

unsafe operating environment.

3.

Bring an air line from your compressed air supply

to the pump location. Be sure the air is dry and

filtered. Install a bleed-type master air valve

upstream from the pump. When it is closed and

the pump air regulator (6a) is opened, the bleed-

type master air valve relieves all air pressure to the

system components.

4.

Ventilate the spray booth.

To prevent hazardous concentrations of toxic and/

or flammable vapors, spray only in a properly venti-

lated spray booth. Never operate the spray gun

~ unless ventilation fans are operating.

Check and follow all of the national, state, and local

codes regarding air exhaust velocity requirements.

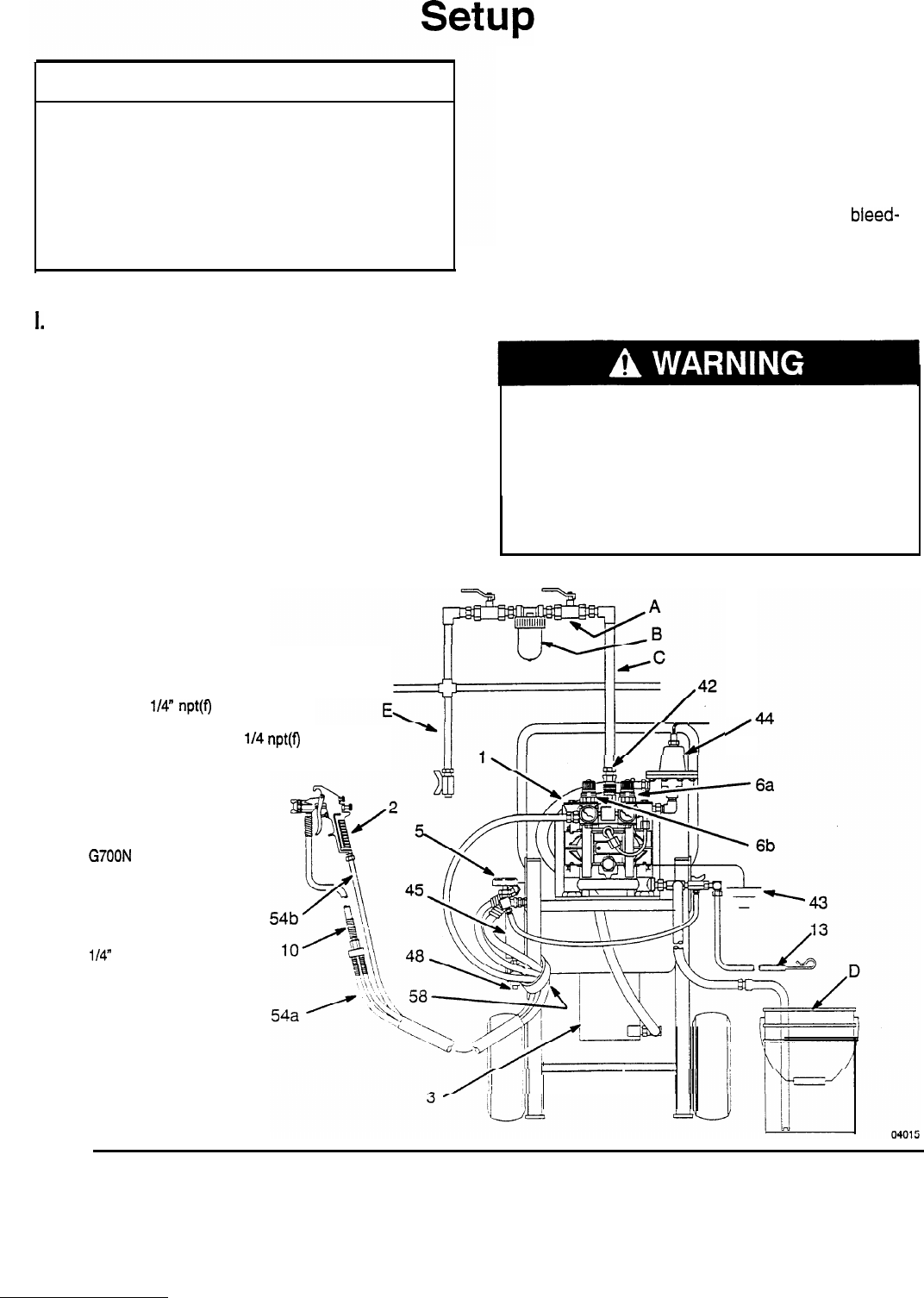

KEY

Components you must supply:

A

Bleed-type master air valve

Required for pump; order part no.

11 O-223,

l/4”

nptQ

B Air filter.

Order part no.

11 O-l 46,

l/4

npt(f)

C Air supply line

D Grounded 5 gallon metal pail

--

E

Air line moisture trap

Components supplied with package:

1

Husky 307 pump

2 G700N

air spray gun

3 Fluid heater

6a

Pump air regulator

6b

Gun air regulator

10

Whip hose

13

Drain hose

42

l/4” female quick

. disconnect coupler

43 Pump ground wire

44 Fluid regulator

45 Fluid filter

48 Filter drain valve

54a

Gun fluid hoses

54b

Gun air hose

I-

58

Tie strap

/’

Fig. 1

4

308-448