Additional Safety Rules for Drilling and Milling

1. Be sure the drill bit or cutting tool is securely locked in the chuck.

2. Be sure the chuck key is removed from the chuck before turning on the power.

3. Adjust the table or depth stop to avoid drilling into the table.

4. Shut off the power, remove the drill bit or cutting tool, and clean the table before leaving the machine.

5. Always use clamps or a vise to hold the workpiece, to prevent it from moving, rotation or flying off

while being machined.

6. Never wear gloves when machining, as they can become entangled in the bit, causing injury.

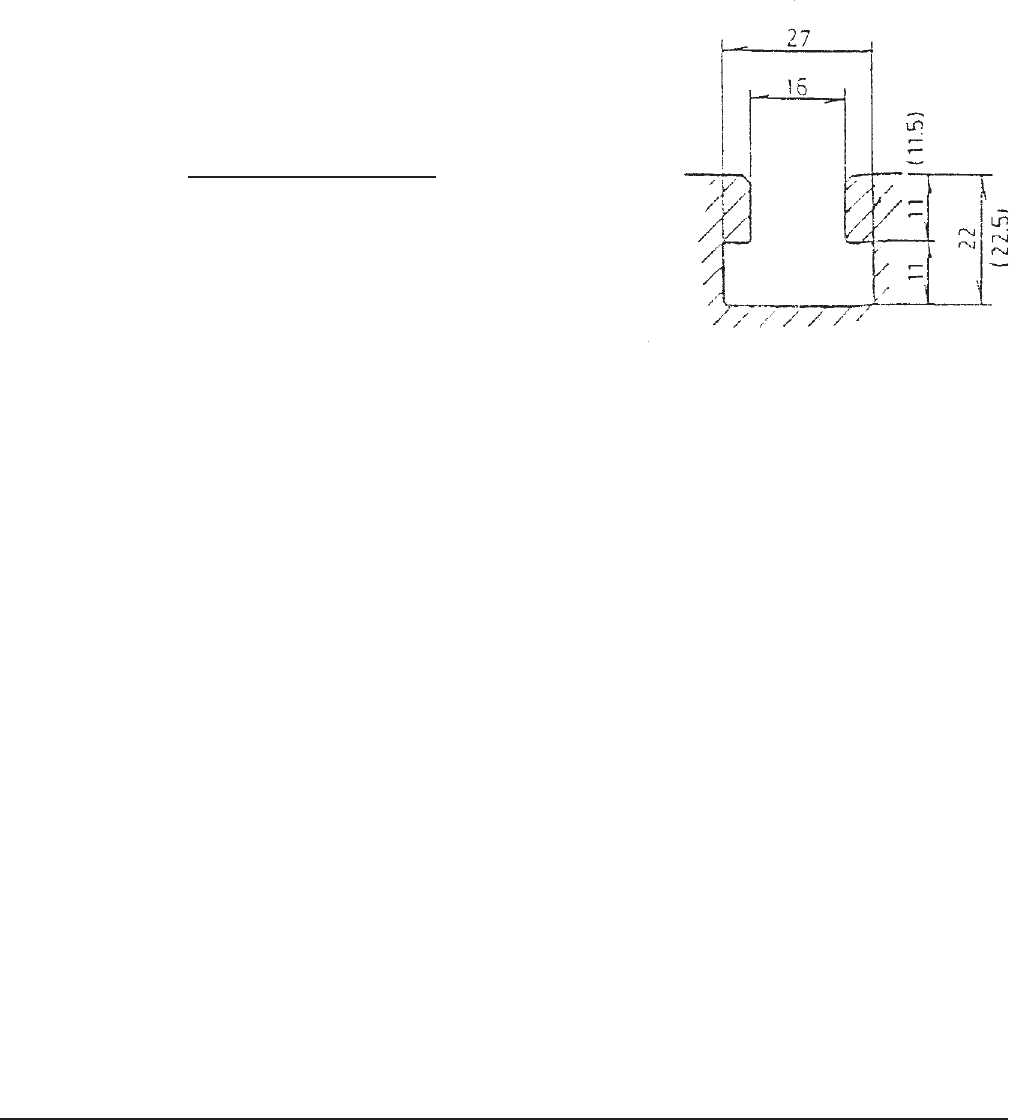

Specification of the T-Slot.

Please refer to Figure 7. Purchase or make T-bolts and

other table top fixtures to fit these dimensions.

NOTE: These dimensions are in millimeters

TROUBLE SHOOTING

The machine doesn’t run when the power switch is turned ON.

1. The knob (#9) is in the STOP position.

2. A fuse has burned out. Check in the switch box, and replace

if necessary.

3. If there is a surge in the current, the circuit breaker may have

opened. Press the circuit breaker back in, if it is in the open

position.

4. The gears may not be engaged. Adjust the speed lever to be sure it is engaged.

The motor overheats, or there is insufficient power.

1. The machine is overloaded. Reduce the feed rate, and/or increase the spindle speed.

2. The voltage supply is too low. If you have an unreliable power supply, check with a qualified electrician

to repair it.

3. The magnetic switch may have a burned or broken contact point. Replace the switch.

4. The contactor relay may be broken. Replace it.

5. The motor carbon brushes may be worn or cracked. Check them and replace if needed.

6. There may be a poor electrical connection. Have a qualified electrician check the wiring and power

supply.

7. The motor may be burned out. After a long period of heavy use, the motor may burn out. If so, replace

the motor.

8. The drill bit or cutting blade may be worn. Sharpen or replace the bits as needed.

The spindle bearing is very hot.

1. There is insufficient lubrication. Turn off the power, and check the bearing for lubrication. If necessary,

apply a medium weight bearing grease.

2. The spindle bearing is worn, or is fixed too tight. Turn off the power, unplug the electrical connection,

and rotate the spindle by hand.

Be sure it turns freely. If not, check the bearing adjustment. If you feel uneveness in the bearing, you will

have to replace it.

3. The spindle has been turning at high speed for a long time. After long use, turn the machine off for a

while to give it a rest, and allow it to cool off.

Page 10 SKU # 42827

Figure 7. T-Slot Dimensions.