3309379

General Repair Information

WARNING

MOVING PARTS HAZARD

To reduce risk of serious injury, do not

touch moving parts with fingers or tools

while testing repair. Shut off sprayer

when repairing. Install all covers, gas-

kets, screws and washers before operat-

ing sprayer.

CAUTION

To reduce risk of pressure control malfunction:

D Use needle nose pliers to disconnect wires. Never

pull on wire, pull on connector.

D Mate wire connectors properly. Center flat blade of

insulated male connector in female connector.

D Route wires carefully to avoid interference with

other connections of pressure control. Do not pinch

wires between cover and control box.

1. Keep all screws, nuts, washers, gaskets, and

electrical fittings removed during repair proce-

dures. These parts are not normally provided with

replacement assemblies.

2. Test repair after problem is corrected.

3. If sprayer does not operate properly, review

repair procedure to verify procedure was done

correctly. If necessary, see Troubleshooting Guide,

page 5, for other possible solutions.

WARNING

HOT SURFACES HAZARD

EXPLOSION HAZARD

Hydraulic reservoir and engine may be

very hot during operation and could burn

skin if touched.

Flammable materials spilled on hot

engine could cause fire or explosion.

Have fan shroud in place during opera-

tion to reduce risk of burns, fire or explo-

sion.

4. Install fan shroud before operation of sprayer

and replace if damaged. Fan shroud directs cool-

ing air around reservoir to prevent overheating. It

can also reduce risk of burns, fire, explosion and

pinching; see preceding WARNING.

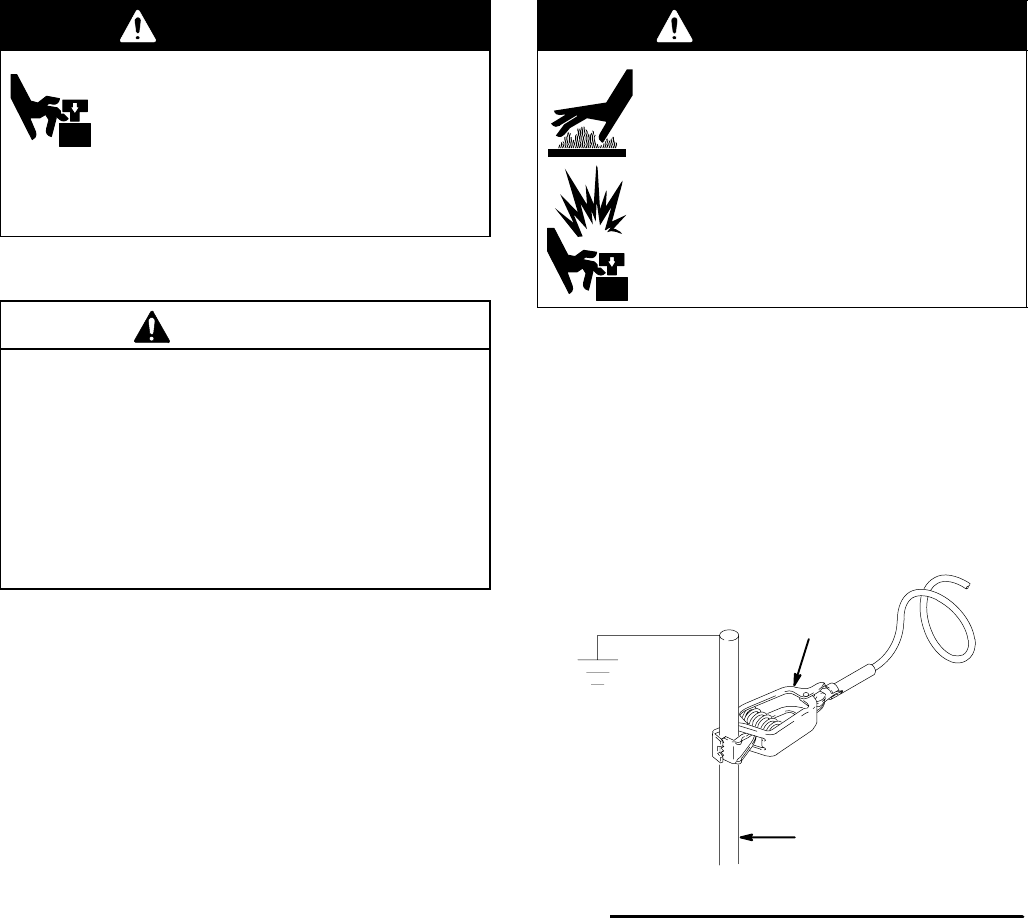

Grounding

Ground sprayer with grounding clamp to earth ground for

safe sprayer operation. Fig. 1.

Fig. 1

06250

water pipe, steel

sign post, or metal

light pole

grounding

clamp