21

MAINTENANCE AND INSPECTION

WARNING

To avoid an accident or personal injury, always

confirm that the trigger switch is turned OFF and the

power plug has been disconnected from the

receptacle before performing any maintenance or

inspection of this tool.

1. Inspecting the saw blade

Always replace the saw blade immediately upon the

first sign of deterioration or damage.

A damaged saw blade can cause personal injury and

a worn saw blade can cause ineffective operation and

possible overload to the motor.

CAUTION

Never use a dull saw blade. When a saw blade is dull,

its resistance to the hand pressure applied by the tool

handle tends to increase, making it unsafe to operate

the power tool.

2 Inspecting the carbon brushes

For your continued safety and electrical shock

protection, carbon brush inspection and replacement

on this tool should ONLY be performed by a Hitachi

Authorized Service Center.

3. About Handling the Motor (see Fig. 1)

Winding of the motor is said to be the heart of this

tool. Exercise utmost caution not to damage the

winding by exposing it to wash oil or water.

NOTE

Accumulation of dust and the like inside the motor

can result in a malfunction.

After using the motor for 50 hours or so, carry out no-

load running, and blow in the dry air from a wind hole

at the motor's rear. Such action is effective to

discharge dust and the like.

4. Inspecting the screws

Regularly inspect each component of the power tool

for looseness.

Re-tighten screws on any loose part.

WARNING

To prevent personal injury, never operate the power

tool if any components are loose.

5. Inspecting the lower guard for proper operation

Before each use of the tool, test the lower guard (see

Fig. 7) to assure that it is in good condition and that it

moves smoothly.

Never use the tool unless the lower guard operates

properly and it is in good mechanical condition.

6. Storage

After operation of the tool has been completed, check

that the following has been performed:

(1) Trigger switch is in OFF position,

(2) Power plug has been removed from the receptacle,

When the tool is not in use, keep it stored in a dry

place out of the reach of children.

7. Replacement of guard

After long-term use, the blade slot in the guard may

widen and require replacement. If the blade slot

should widen, replace the guard with a new one. After

replacing, make a groove on it. Refer to “1. Cutting a

groove on the guard” on page 8.

Fig. 56

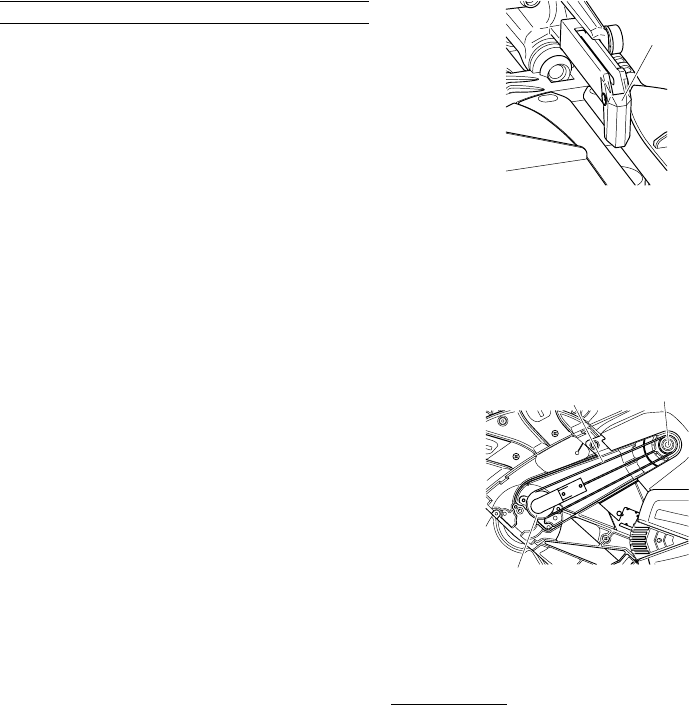

8. Replacement of Poly-V-Belt

The power of the motor is transmitted to the saw blade

by a Poly-V-Belt. When the Poly-V-Belt is broken or

damaged, remove the belt cover by loosening the four

5 mm screws (see Fig. 2) and replace the damaged

one with the new one.

When connecting the belt on pulleys, first connect 2

or 3 teeth of Poly-V-Belt to the grooves of the pulley

(A) and pulley (B). Then turning the pulley (A) and

pulley (B), connect all 13 teeth of the belt to the pulleys.

Fig. 57

9. Lubrication

Lubricate the following sliding surfaces once a month

to keep the power tool in good operating condition

for a long time (see Fig. 1 and Fig. 2). Use of machine

oil is recommended.

Oil supply points:

* Rotary portion of hinge

* Rotary portion of vise assembly

* Rotary portion of holder (A)

10. Cleaning

Periodically remove chips, dust and other waste

material from the surface of the power tool, especially

from the inside of the lower guard with a damp, soapy

cloth. To avoid a malfunction of the motor, protect it

from contact with oil or water.

If the laser line becomes invisible due to chips and

the like adhered onto the window of the laser marker's

light-emitting section, wipe and clean the window with

a dry cloth or a soft cloth moistened with soapy water,

etc.

11. Replacing supply cord

If the supply cord of Tool is damaged, the Tool must

be returned to Hitachi Authorized Service Center for

the cord to be replaced.

Guard

Poly-V-belt

Pulley (B)

Pulley (A)

03Eng_C12LSH_Eng 4/26/07, 5:33 PM21