10

English

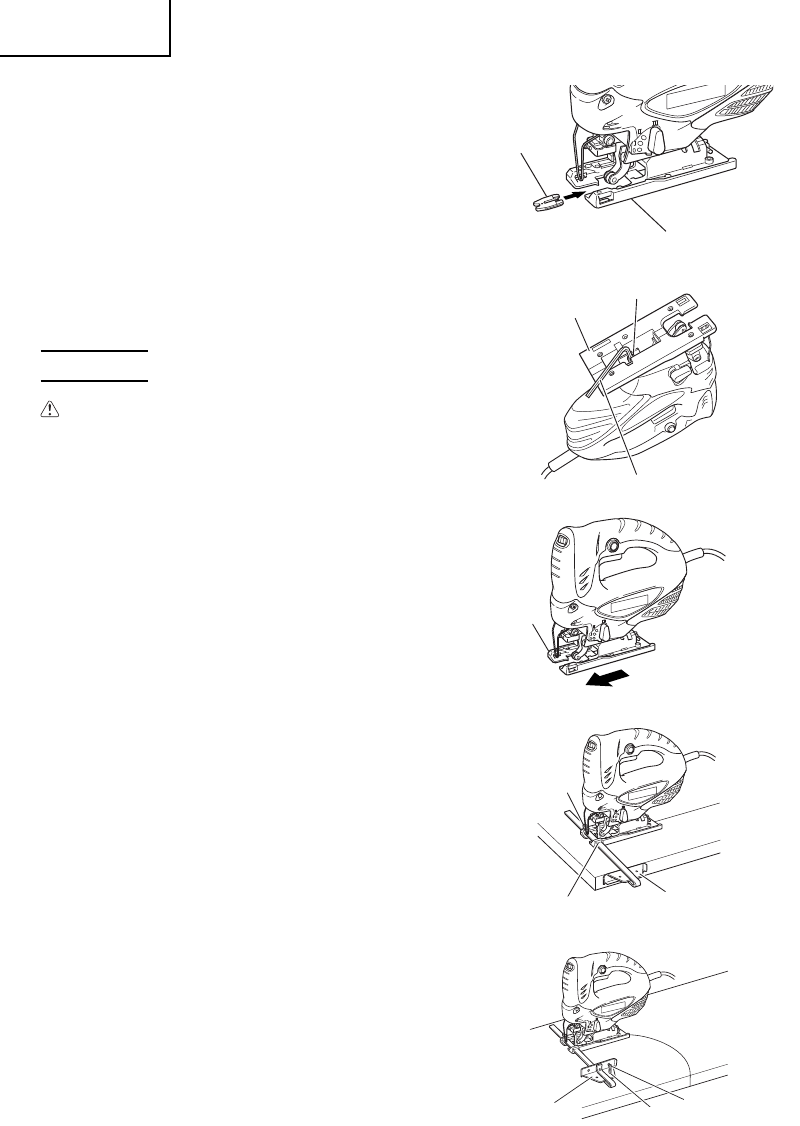

Fig. 7

Splinter

guard

Base

Fig. 10

Fig. 8

Base

Base bolt

Allen wrench

M5 bolt

Attachment hole

Guide

Fig. 11

Guide

Nail or screw

Guide hole

Fig. 9

Base

10. Splinter guard (Sold separately)

Using the splinter guard when cutting wood

materials will reduce splintering of cut surfaces.

Insert the splinter guard in the space on the base,

and push it completely. (see Fig. 7)

11. Sub base (Sold separately)

Using the sub base (made from steel) will reduce

abrasion of aluminium base especially in cutting

metals.

Using the sub base (made from resin) will reduce

scratching of cut surface. Attach the sub base to

the bottom surface of base by attached 4 screws.

CUTTING

CAUTION:

● In order to prevent blade dislodging, damage

or excessive wear on the Plunger, please

make sure to have surface of the base plate

attached to the work piece while sawing.

1. Rectilinear cutting

When cutting on a straight line, fi rst draw a

marking gauge line and advance the saw along

that line. Using the guide (sold separately) will

make it possible to cut accurately on a straight

line.

(1) Loosen the base bolt allen wrench attached on

base. (Fig. 8)

(2) Move the base fully forward (Fig. 9), and tighten

the base bolt again.

(3) Attach the guide by passing it through the

attachment hole on the base and tighten the M5

bolt. (Fig. 10)

(4) Set the orbital position to “0”.

NOTE: To ensure accurate cutting when using the

Guide (Fig. 8), always set the orbital position

to “0”.

2. Sawing curved lines

When sawing a small circular arc, reduce the

feeding speed of the machine. If the machine is

fed too fast, it could cause the blade to break.

3. Cutting a circle or a circular arc

The guide also will be helpful for circular cutting.

After attaching the guide by same way noted as

above, drive the nail or screw into the material

through the hole on the guide, then use it for a

axis when cutting. (Fig. 11)

NOTE: Circular cutting must be done with the blade

approximately vertical to the bottom surface

of the base.