5

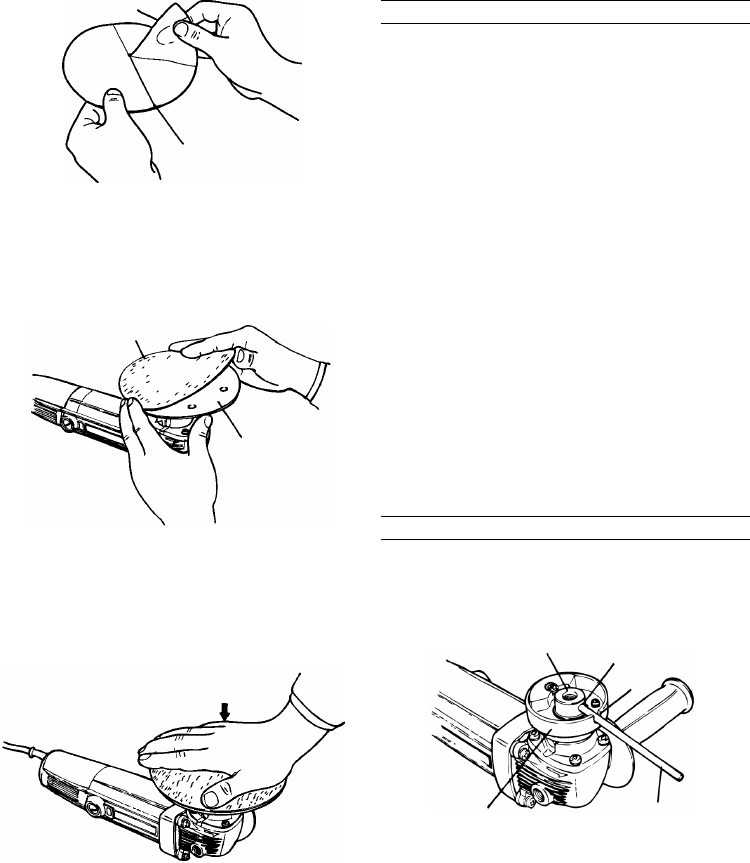

(2) After ensuring that the sanding pad is free of dust

and oil, mount the sanding paper to the sanding

pad as shown in Fig. 2, ensuring that the outer

circumferences of the pad and paper are matched.

(3) Ensure that the sanding paper is securely attached

to the pad by pressing the paper strongly with the

palm of the hand, as shown in Fig. 3.

CAUTION

If the sanding paper is not attached securely as

described above, it could come off during operation,

inviting serious injury. As the adhesive may

deteriorate if the sanding paper is removed and

reattached several times, the sanding paper should

be aligned and attached securely in a single operation.

PRACTICAL OPERATING PROCEDURES

1. Turn the sander on after lightly applying it to the

surface to be sanded. Never leave the rotating tool

unattended.

2. Do not apply excessive pressure to the sander.

Excessive pressure may result in deterioration of

the sanded surface, and overloading of the tool.

3. Hold the housing and side handle of the sander

securely during operation.

4. The sanding paper should be removed as soon as

possible after completion of the operation. Sanding

paper left on the pad for several days may be very

difficult to remove.

5. After removing the sanding paper, ensure that any

adhesive remaining on the sanding pad is removed

completely by wiping it. Should any adhesive remain,

dust and dirt will adhere to the pad, resulting in

reduced adhesion when another sanding paper is

mounted.

6. Do not attempt to reattach sanding paper to the

pad once it has been removed. Reduced adhesive

strength could cause the sanding paper to come

flying off the pad, creating a serious hazard.

CAUTION

Immediately after use, DO NOT Iay the tool down

or touch the sanding pad until the rotation parts of

the tool come to a complete stop. Laying the tool

down in this manner could cause grit and dirt to

be sucked into the tool. Touching the rotating sanding

paper could cause serious injury.

REPLACING A SANDING PAD

1. Insert the accessory bar wrench into the groove of

the spindle connector and the opening of the pad

spindle, as shown in Fig. 4.

2. Holding the bar wrench, the sanding pad is tightened

by rotating in to the right (clockwise), and loosened

by rotating it to the left (counterclockwise), as shown

in Fig. 5.

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Lining paper

Slit part

Sanding paper

Sanding pad

Press strongly

Pad spindle

Opening

Groove

Spindle connector

Bar wrench

01Eng_SAY-150A_Eng 11/20/08, 11:125