English

11

CAUTION:

⅜

Do not expose directly your eye to the light by looking into the light.

If your eye is continuously exposed to the light, your eye will be hurt.

NOTE:

⅜

To prevent the battery power consumption caused by forgetting to turn off

the LED light, the light goes off automatically in about 15 minutes.

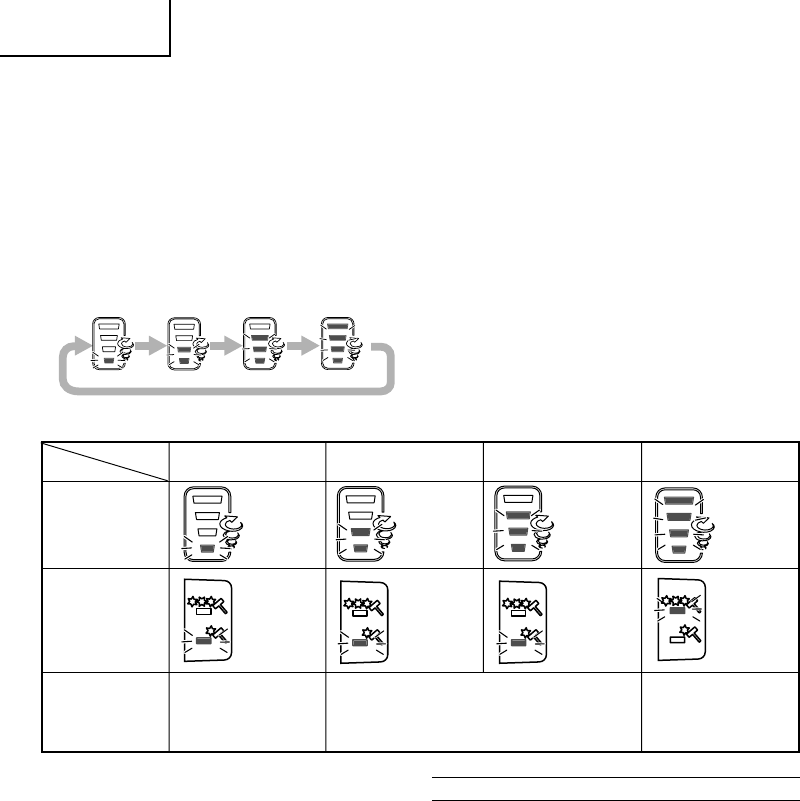

6. Tightening mode selector function (Fig. 12)

CAUTION:

⅜

Do not subject the switch panel to shock or damage.

⅜

Select high/low mode and single/continuous mode while the trigger switch

is released. Failure to do so could result in malfunction.

(1) High/Low selector switch

The rotation speed changes in 4 steps (900, 1400, 2000, 2600/2900 min

-1

)

each time the high/low selector switch is pressed.

(2) Single/Continuous selector switch

The tightening torque can be adjusted according to the work by changing

the tightening mode using the single/continuous selector switch and the

high/low selector switch on the side of the impact driver.

When the forward/reverse button is set to reverse, the high/low mode and

single/continuous mode are set to “High” and “Continuous” respectively,

regardless of the indicators on the switch panel.

The mode switches between single and continuous mode each time the

single/continuous selector switch is pressed.

In single mode, after the trigger switch has been pulled to start operation,

bolt-tightening stops automatically after 1 to 4 tightenings.

In continuous mode, when the trigger switch is pulled to start operation,

bolt-tightening continues (without stopping automatically).

NOTE:

⅜

The appropriate mode differs depending on the screw and the material

being screwed. Drive in a few test screws and adjust the mode setting

accordingly.

⅜

The high/low and single/continuous selector switches can only be set after

the battery has been installed in the driver and the trigger switch has been

pulled once.

Examples of tightening mode selector function settings

Low 1 Low 2 Medium High

Rotation speed

2600 min

-1

900 min

-1

1400 min

-1

2000 min

-1

/2900 min

-1

Single/Continuous

Single Single Single Continuous

Use

“Delicate work”

Tightening small diameter

screws (M6 or similar), etc.

“Light load work”

Affixing plasterboard (select according to the hardness of the

base material) etc.

“Heavy load work”

Tightening long screws,

coach screws, bolts, etc.

7. Tightening and loosening screws (WH14DBDL / WH18DBDL)

Install the bit that matches the screw, line up the bit in the grooves of the head

of the screw, then tighten it.

Push the impact driver just enough to keep the bit fitting the head of the

screw.

CAUTION

Applying the impact driver for too long tightens the screw too much and

can break it.

Tightening a screw with the impact driver at an angle to that screw can

damage the head of the screw and the proper force will not be transmitted

to the screw.

Tighten with this impact driver lined up straight with the screw.

8. Tightening and loosening bolts

A hex. socket matching the bolt or nut must first be selected. Then mount

the socket on the anvil, and grip the nut to be tightened with the hex. socket.

Holding the wrench in line with the bolt, press the power switch to impact

the nut for several seconds.

If the nut is only loosely fitted to the bolt, the bolt may turn with the nut,

therefore mistaking proper tightening. In this case, stop impact on the nut

and hold the bolt head with a wrench before restarting impact, or manually

tighten the bolt and nut to prevent them slipping.

OPERATIONAL CAUTIONS

1. Resting the unit after continuous work

After use for continuous bolt-tightening work, rest the unit for 15 minutes or

so when replacing the battery. The temperature of the motor, switch, etc.,

will rise if the work is started again immediately after battery replacement,

eventually resulting in burnout.

NOTE:

Do not touch the metal parts, as it gets very hot during continuous work.

2. Cautions on use of the speed control switch

This switch has a built-in, electronic circuit which steplessly varies the

rotation speed. Consequently, when the switch trigger is pulled only slightly

(low speed rotation) and the motor is stopped while continuously driving in

screws, the components of the electronic circuit parts may overheat and be

damaged.

3. Use a tightening time suitable for the screw

The appropriate torque for a screw differs according to the material and size

of the screw, and the material being screwed etc., so please use a tightening

time suitable for the screw. In particular, if a long tightening time is used in

the case of screws smaller than M8, there is a danger of the screw breaking,

so please confirm the tightening time and the tightening torque beforehand.

01Eng_WH14DBDL_EE 12/28/10, 16:4511