8

NOTE

⅜ Perform cutting by overlapping the ink line with the

laser line.

⅜ When the ink line and the laser line are overlapped,

the strength and weakness of light will change,

resulting in a stable cutting operation because you

can easily discern the conformity of lines. This ensures

the minimum cutting errors.

⅜ In outdoor or near-the-window operations, it may

become difficult to observe the laser line due to the

sunlight. Under such circumstances, move to a place

that is not directly under the sunlight and engage in

the operation.

⅜ Do not tug on the cord behind the motor head or hook

your finger, wood and the like around it; otherwise,

the cord may come off and the laser marker may not

be lit up.

⅜ Check and make sure on a periodic basis if the position

of the laser line is in order. As regards the checking

method, draw a right-angle ink line on the workpiece

with the height of about 38 mm and the width of 89

mm, and check that the laser line is in line with the

ink line [The deviation between the ink line and the

laser line should be less than the ink line width (0.5

mm)] (Fig. 13).

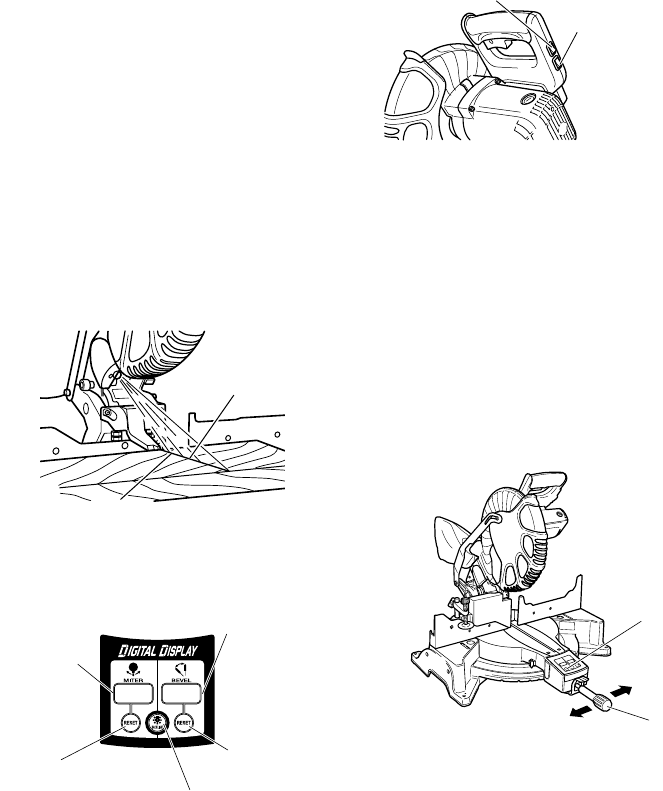

Fig. 13

8. DIGITAL DISPLAY PANEL (for C12LCH and C12LC)

Fig. 14

(1) Turning on the digital display switch shows 0° for both

miter and bevel angle, regardless of main unit angle.

(2) Align the main unit angle with the tilt angle (0°) and

miter angle (0°) and hold down their reset buttons for

at least 0.2 seconds.

(3) Turning on the laser marker switch while the digital

display switch is on, lights up the laser marker. (On

the C12FCH, only the laser marker switch.)

Fig. 15

CAUTION

⅜ When operating the digital panel, have the motor head

section at the top limit position and the blade stopped.

⅜ If the figure shown on the miter angle digital display

is different from the positive stop angle (for example,

45.0° → 45.5°, 31.6° → 32.0°) then the positive stop

has probably deviated slightly from its correct

position. If this happens, do as follows.

(1) Move the turntable left and right with the side

handle loosened, and set the turntable to the

correct position.

(2) If the figures on the display and positive stop still

do not match, then return the turntable to the 0°

position. Next move the turntable left and right

with the side handle loosened as shown in Fig.

15. After setting it to the correct position 0°, press

the reset button again.

Move the turntable left and right with the side

handle loosened and set it to the correct position.

Fig. 16

NOTE

⅜ Before starting to cut, align the main unit to the miter

angle 0° and the bevel angle 0° and hold down the

reset buttons for at least 0.2 seconds. If you press the

digital display switch to ON without aligning the main

unit to 0°, then the figures appearing on the digital

display and the main unit angle will not match.

⅜ The laser marker will not light up if the digital display

switch is turned off. (only on C12LCH)

Laser line

Marking (pre-marked)

Miter angle

window

(Displays arrows

show angle and

direction that

turntable is

rotating. Left is

←, Right is →.)

Bevel angle

window

(Displays arrows

showing motor

head bevel angle

and bevel

direction. Left is

←, Right is →.)

Miter angle

reset button

Bevel angle

reset button

Back light ON/OFF switch (Press

and the switch illuminates. Press

again and the lighting turns off.)

Laser marker switch

(for C12LCH/C12FCH)

Digital display switch

(for C12LCH/C12LC)

(Also serves as laser

marker power switch.)

Reset Button

Side Handle

01Eng_C12LCH_Eng 4/11/07, 6:55 PM8