OM-235 281 Page 24

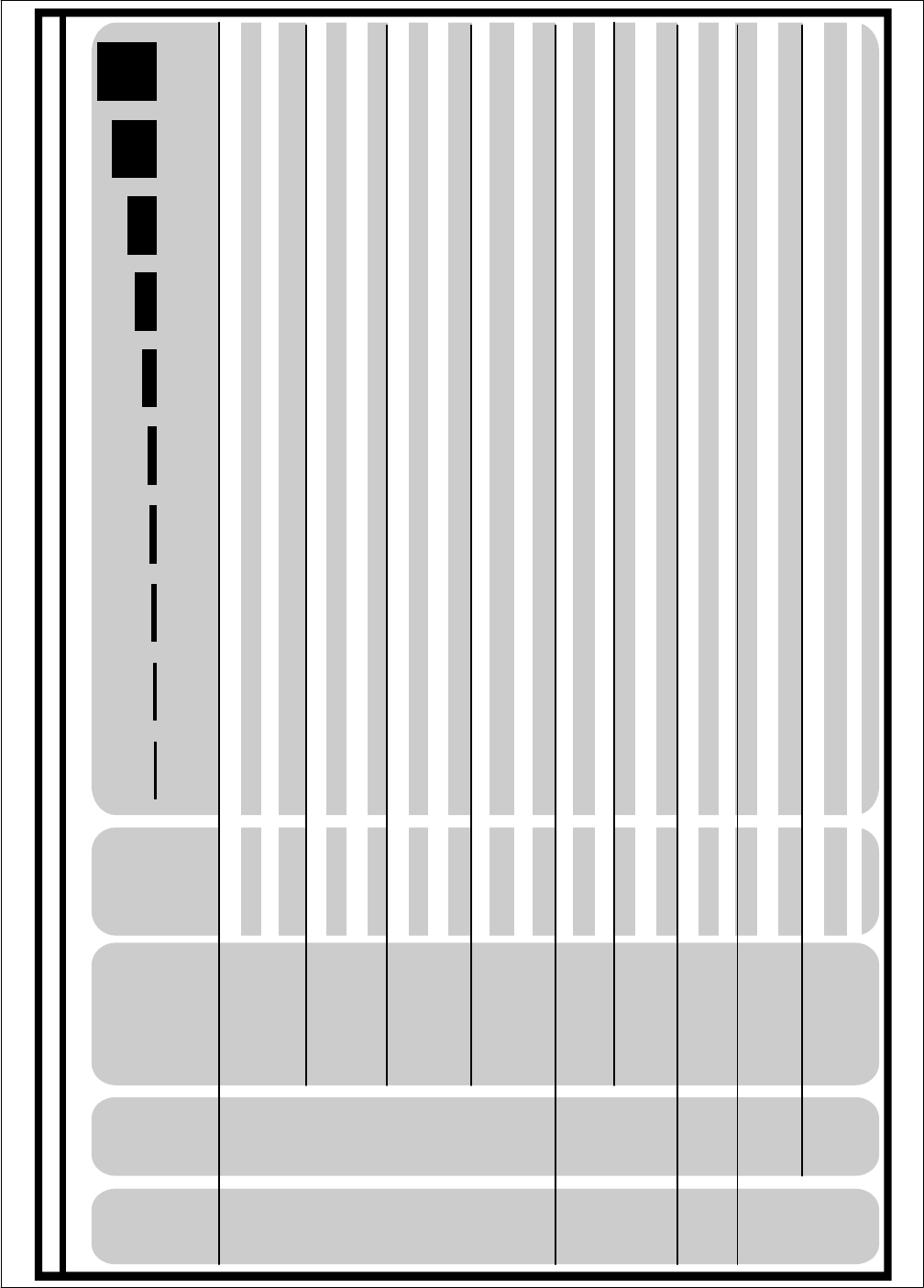

4-2. Weld Parameters

Selecting Wire, Gas and Control Settings

Settings are approximate and are based on a 230 Input line voltage. Adjust as required.

Thicker materials can be welded using proper technique, joint preparation and multiple passes.

.024” ( 0.6mm )

.030” ( 0.8mm )

.035” ( 0.9mm )

.045” ( 1.1mm )

.024” ( 0.6mm )

.030” ( 0.8mm )

.035” ( 0.9mm )

.045” ( 1.1mm )

.024” ( 0.6mm )

.030” ( 0.8mm )

.035” ( 0.9mm )

.045” ( 1.1mm )

.024” ( 0.6mm )

.030” ( 0.8mm )

.035” ( 0.9mm )

.045” ( 1.1mm )

.024” ( 0.6mm )

.030” ( 0.8mm )

.035” ( 0.9mm )

.024” ( 0.6mm )

.030” ( 0.8mm )

.035” ( 0.9mm )

.030” ( 0.8mm )

.035” ( 0.9mm )

.045” ( 1.1mm )

.030” ( 0.8mm )

.035” ( 0.9mm )

.047” ( 1.2mm )

.030” ( 0.8mm

)035” ( 0.9mm

).047” ( 1.2mm )

Diameter

of Wire

Being Used

C

25

Gas Mixture

75% Ar / 25% CO

2

Produces less spatter

Better Appearance

92% Ar / 8%

CO

2

or

90% Ar / 10% CO

2

Tri–Mix

90% HE / 7.5% Ar /

2.5% CO

2

No Shielding Gas Required

Good for Windy or

Outdoor Applications

100% Argon**

100% Argon**

Suggested

Shielding Gases

20–30 cfh Flow Rate

Solid Wire

ER70S–6

“Set Polarity”

for (DCEP)”

Stainless

Steel

“Set Polarity”

for (DCEP)”

Flux Core

E71T–GS

“Set Polarity”

for (DCEN)”

Aluminum**

4043 AL

(DCEP)

Aluminum**

5356 AL

(DCEP)

Wire Type,

and

Polarity Set-

ting

Steel

Stainless

Steel

Steel

Aluminum

With Optional

DP 3545

Spoolgun

Material

Being

Welded

235268A

Recommended Voltage and Wire Speed Settings for Thickness of Metal Being Welded

Number on Left is Voltage Setting / Number on Right is Wire Feed Setting

1/2 inch

( 12.7mm )

——

9 / 62

6 / 38

7 / 30

——

7 / 70

7 / 54

6 / 32

——

8 / 70

7 / 46

6 / 34

——

8 / 62

8 / 60

——

8 / 78

10 / 70

7 / 54

8 / 50

9 / 50

10 / 66

11 / 60

12 / 34

12 / 98

12 / 82

12 / 42

8 / 74

8 / 70

7 / 50

6 / 34

——

9 / 62

6 / 38

7 / 30

——

7 / 70

7 / 54

6 / 32

——

8 / 70

7 / 46

6 / 34

——

8 / 62

8 / 60

——

7 / 76

10 / 70

7 / 54

8 / 50

8 / 44

9 / 60

10 / 52

11 / 30

10 / 82

10 / 58

11 / 38

3/8 inch

( 9.5mm )

7 / 70

7 / 60

6 / 44

6 / 34

9 / 90

8 / 50

6 / 38

7 / 30

——

7 / 70

7 / 54

6 / 32

——

7 / 60

7 / 46

6 / 34

——

8 / 62

8 / 60

——

6 / 76

9 / 62

7 / 54

7 / 44

7 / 38

8 / 46

9 / 50

10 / 26

9 / 76

9 / 54

10 / 34

1/4 inch

( 6.3mm )

6 / 70

6 / 46

5 / 40

5 / 26

8 / 74

7 / 46

6 / 36

7 / 30

——

6 / 60

6 / 42

5 / 30

——

6 / 46

6 / 40

5 / 32

——

8 / 62

7 / 58

——

6 / 68

9 / 60

6 / 50

6 / 40

6 / 32

7 / 42

8 / 40

9 / 24

8 / 60

8 / 46

9 / 34

3/16 inch

( 4.8mm )

5 / 50

5 / 36

5 / 34

4 / 24

7 / 70

6 / 46

5 / 34

6 / 26

——

5 / 40

5 / 40

5 / 26

5 / 58

5 / 36

5 / 40

5 / 30

6 / 60

7 / 60

6 / 50

6 / 80

4 / 52

7 / 64

5 / 44

5 / 38

5 / 28

6 / 40

7 / 34

——

6 / 50

7 / 44

7 / 28

1/8 inch

( 3.2mm )

4 / 40

4 / 30

3 / 30

3 / 22

5 / 46

5 / 40

4 / 28

4 / 18

4 / 44

4 / 34

3 / 34

3 / 22

4 / 40

4 / 30

3 / 32

3 / 22

5 / 48

5 / 36

5 / 44

3 / 44

3 / 40

4 / 40

3 / 34

3 / 26

3 / 20

3 / 36

4 / 34

——

3 / 36

4 / 36

——

14 gauge

.075 inch

( 2.0mm )

3 / 40

3 / 34

3 / 26

2 / 20

4 / 40

4 / 36

4 / 24

3 / 18

3 / 40

3 / 34

3 / 26

2 / 20

3 / 40

3 / 34

3 / 28

2 / 20

4 / 46

4 / 36

4 / 36

2 / 38

2 / 36

3 / 36

2 / 26

2 / 20

——

2 / 36

3 / 30

——

2 / 36

3 / 36

——

16 gauge

.062 inch

( 1.6mm )

3 / 34

3 / 30

2 / 30

——

4 / 34

3 / 36

3 / 24

——

3 / 36

3 / 30

2 / 24

——

3 / 36

3 / 30

2 / 26

——

4 / 40

4 / 32

3 / 32

2 / 34

2 / 32

3 / 34

1 / 24

——

——

——

2 / 24

——

——

——

——

18 gauge

.048 inch

( 1.2mm )

2 / 26

1 / 26

——

——

2 / 26

——

——

——

1 / 32

1 / 26

——

——

1 / 32

1 / 26

——

——

2 / 30

2 / 30

2 / 26

1 / 28

1 / 30

2 / 26

——

——

——

——

——

——

——

——

——

22 gauge

.030 inch

( 0.8mm )

1 / 22

1 / 20

——

——

2 / 24

——

——

——

1 / 30

1 / 20

——

——

1 / 30

1 / 20

——

——

——

——

——

——

——

——

——

——

——

——

——

——

——

——

——

24 gauge

.024 inch

( 0.6mm )

9 / 90

9 / 76

7 / 50

6 / 34

98% Ar / 2% CO

2

98% Ar / 2% CO

2

100% CO

2