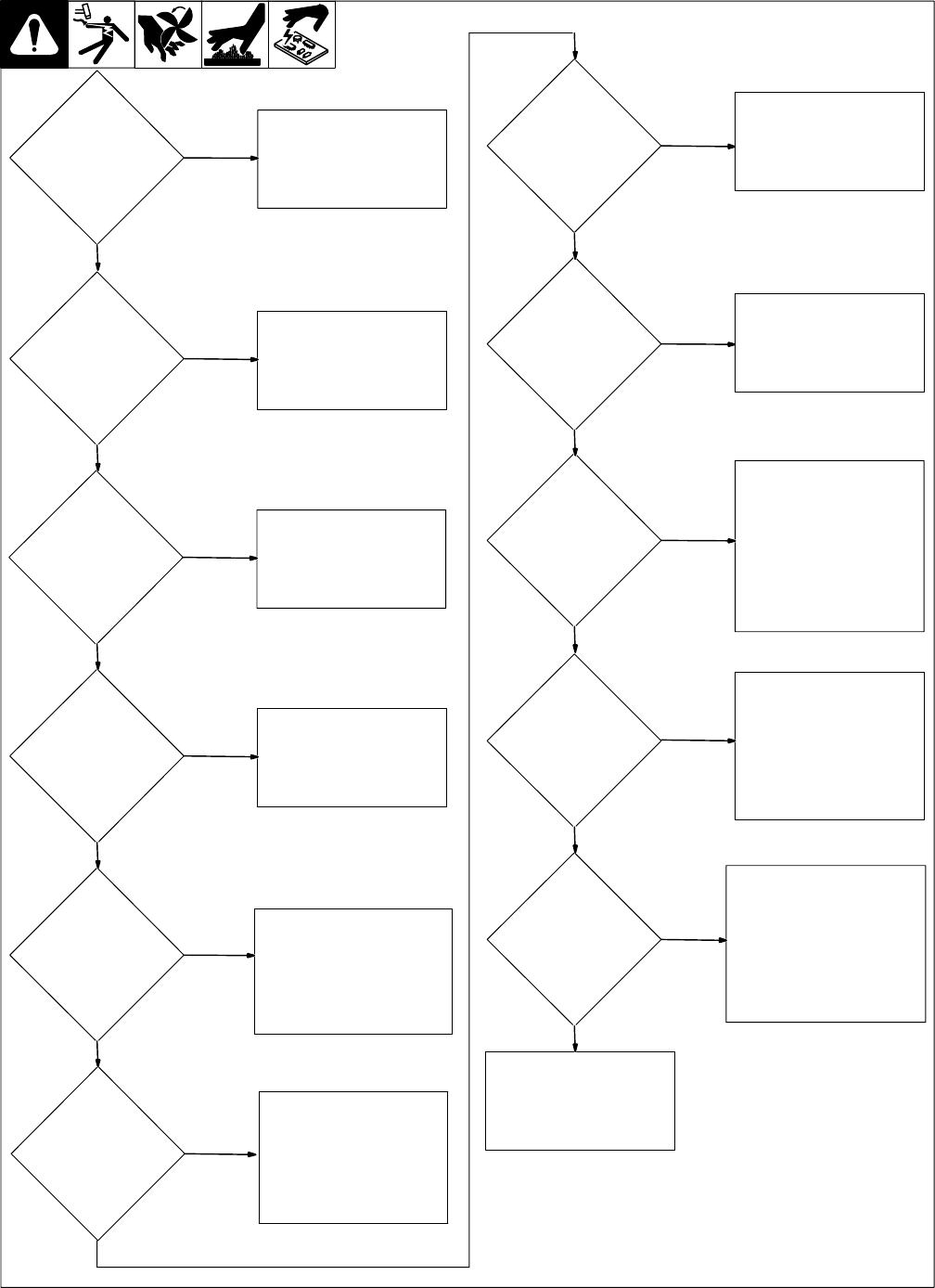

OM-203 653 Page 22

6-5. Troubleshooting Power Source

Connect unit to proper input

voltage (see Section 4-8).

Yes

No

Is input power

connected to

correct line

voltage?

Is Changeover

switch S2 in

the 115V or

230V position?

Place Changeover switch in

proper position for input

voltage (see Section 4-8).

No

Yes

Is the cooling

fan running?

Check Power switch S1 and

relay CR2 and thermistor R1

on PC2. Replace PC2 if R1

or CR2 are not functioning

correctly.

No

Yes

Is Power light

flashing?

Reset Power switch S1

and verify line power

voltage (see Section 4-1).

Check relay CR2,

thermistor R1 on PC2,

and Control board PC1.

No

No

Yes

Turn Output control

fully counterclockwise (see

Section 5-1). Check for

gas/air flow at torch. Check

Control board PC1,

pressure switch S3 (gauge),

air filter, valve AS1, and air

supply connection to unit

and torch.

No

Yes

Is Pressure Status

light On or flashing?

Press torch trigger and

check if pilot arc ignites.

Check torch consumables.

*Check torch connections,

air filter, pressure switch S3,

valve AS1, air supply

connection to unit, torch,

and PC1.

Yes

No

Does pilot arc

ignite?

Place torch near workpiece

and check if pilot arc “jumps”

or transfers to workpiece.

Check work clamp

connection. *Check Control

board PC1 and connections,

and torch and its connections.

Yes

No

Does pilot arc

transfer to

workpiece?

Check all connections,

Check main transformer T1,

Check boost inductor L1

and buck inductor L2.

Return to beginning of chart.

*Servicing procedure to be

performed only by authorized

Service Station.

*

*

*

Is Cup Status

light On or

flashing?

Check torch consumables.

Reset Power switch S1.

Yes

Is Power switch

S1 in the On

position?

Place Power switch in the

On position. (see Section

5-1).

Is Temp Status

light On?

If unit is overheated, wait

while fan cools down unit

temperature.

Yes

No

No

No

Yes

Does the breaker

trip when unit is set

on 115V?

Turn down output current.

(see Section 5-1).

Yes