OM-4418 Page 41

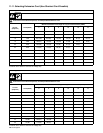

12-10. Butt Joints

S-0662

1 Tack Welds

Prevent edges of joint from drawing

together ahead of electrode by tack

welding the materials in position be-

fore final weld.

2 Square Groove Weld

Good for materials up to 3/16 in (5

mm) thick.

3 Single V-Groove Weld

Good for materials 3/16 − 3/4 in

(5-19 mm) thick. Cut bevel with oxy-

acetylene or plasma cutting equip-

ment. Remove scale from material

after cutting. A grinder can also be

used to prepare bevels.

Create 30 degree angle of bevel on

materials in V-groove welding.

4 Double V-Groove Weld

Good for materials thicker than 3/16

in (5 mm).

30°

2

1

1/16 in

(1.6 mm)

3

4

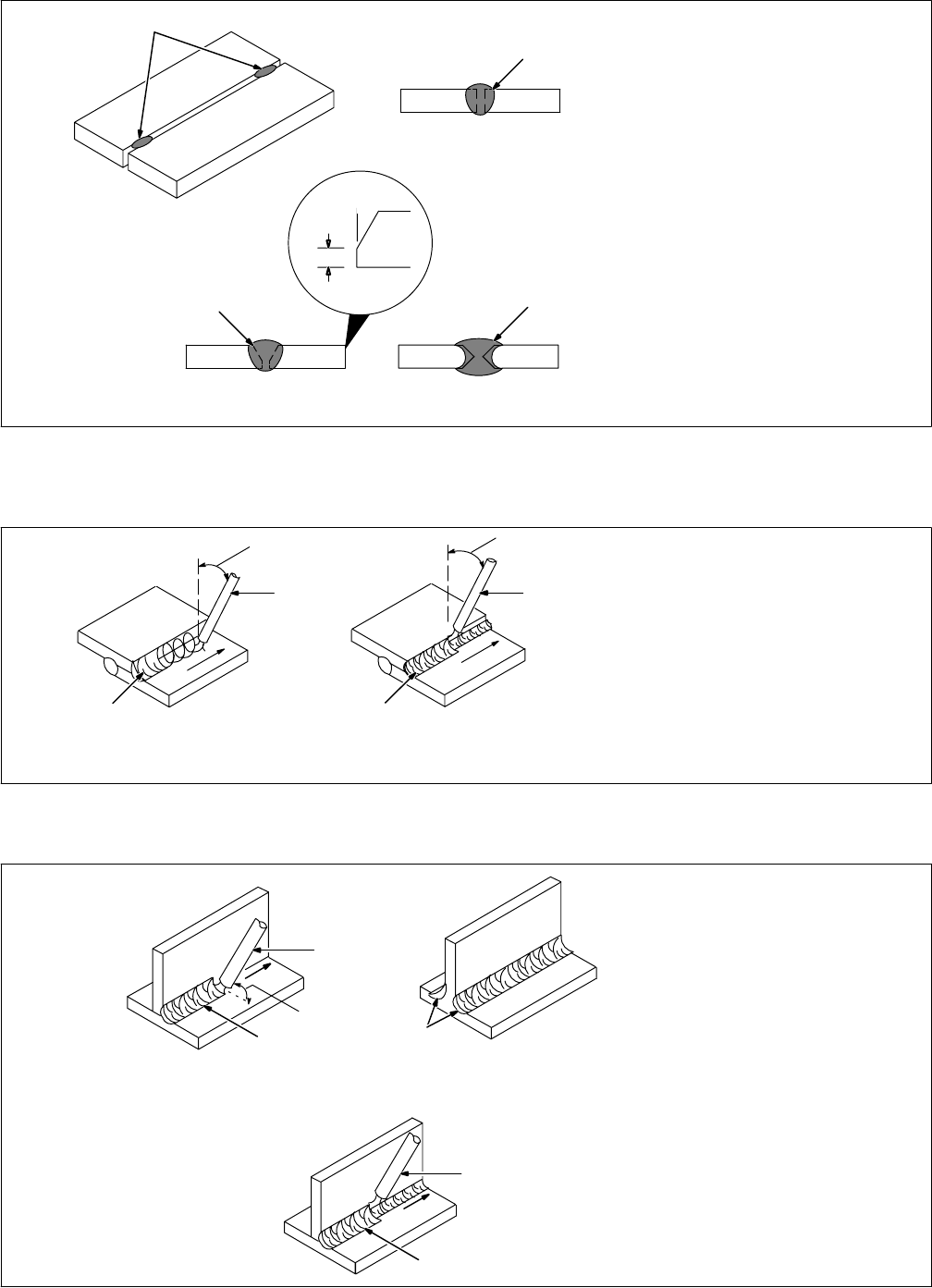

12-11. Lap Joint

S-0063 / S-0064

1 Electrode

2 Single-Layer Fillet Weld

Move electrode in circular motion.

3 Multi-Layer Fillet Weld

Weld a second layer when a heavi-

er fillet is needed. Remove slag be-

fore making another weld pass.

Weld both sides of joint for maxi-

mum strength.

30°

Or Less

Single-Layer Fillet Weld

Multi-Layer Fillet Weld

30°

Or Less

11

2

3

12-12. Tee Joint

S-0060 / S-0058-A / S-0061

1 Electrode

2 Fillet Weld

Keep arc short and move at definite

rate of speed. Hold electrode as

shown to provide fusion into the

corner. Square edge of the weld

surface.

For maximum strength weld both

sides of upright section.

3 Multi-Layer Deposits

Weld a second layer when a heavi-

er fillet is needed. Use any of the

weaving patterns shown in Section

12-9. Remove slag before making

another weld pass.

45°

Or Less

1

2

1

3

2