OM-240 438 Page 52

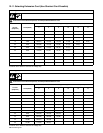

13-2. Electrode and Amperage Selection Chart

Ref. S-087 985-A

3/32

1/8

5/32

3/16

7/32

1/4

1/16

5/64

3/32

1/8

5/32

3/16

7/32

1/4

3/32

1/8

5/32

3/16

7/32

1/4

3/32

1/8

5/32

3/16

7/32

1/4

3/32

1/8

5/32

3/16

7/32

1/4

3/32

1/8

5/32

3/16

3/32

1/8

5/32

6010

&

6011

6013

7014

7018

7024

Ni-Cl

308L

50

100

150

200

250

300

350

400

450

ELECTRODE

DC*

AC

POSITION

PENETRATION

USAGE

MIN. PREP, ROUGH

HIGH SPATTER

GENERAL

SMOOTH, EASY,

FAST

LOW HYDROGEN,

STRONG

SMOOTH, EASY,

FASTER

CAST IRON

STAINLESS

DEEP

DEEP

LOW

MED

LOW

LOW

LOW

ALL

ALL

ALL

ALL

ALL

FLAT

HORIZ

FILLET

ALL

ALL

EP

EP

EP,EN

EP,EN

EP

EP,EN

EP

EP

6010

6011

6013

7014

7018

7024

NI-CL

308L

*EP = ELECTRODE POSITIVE (REVERSE POLARITY)

EN = ELECTRODE NEGATIVE (STRAIGHT POLARITY)

ELECTRODE

AMPERAGE

RANGE

DIAMETER

MED

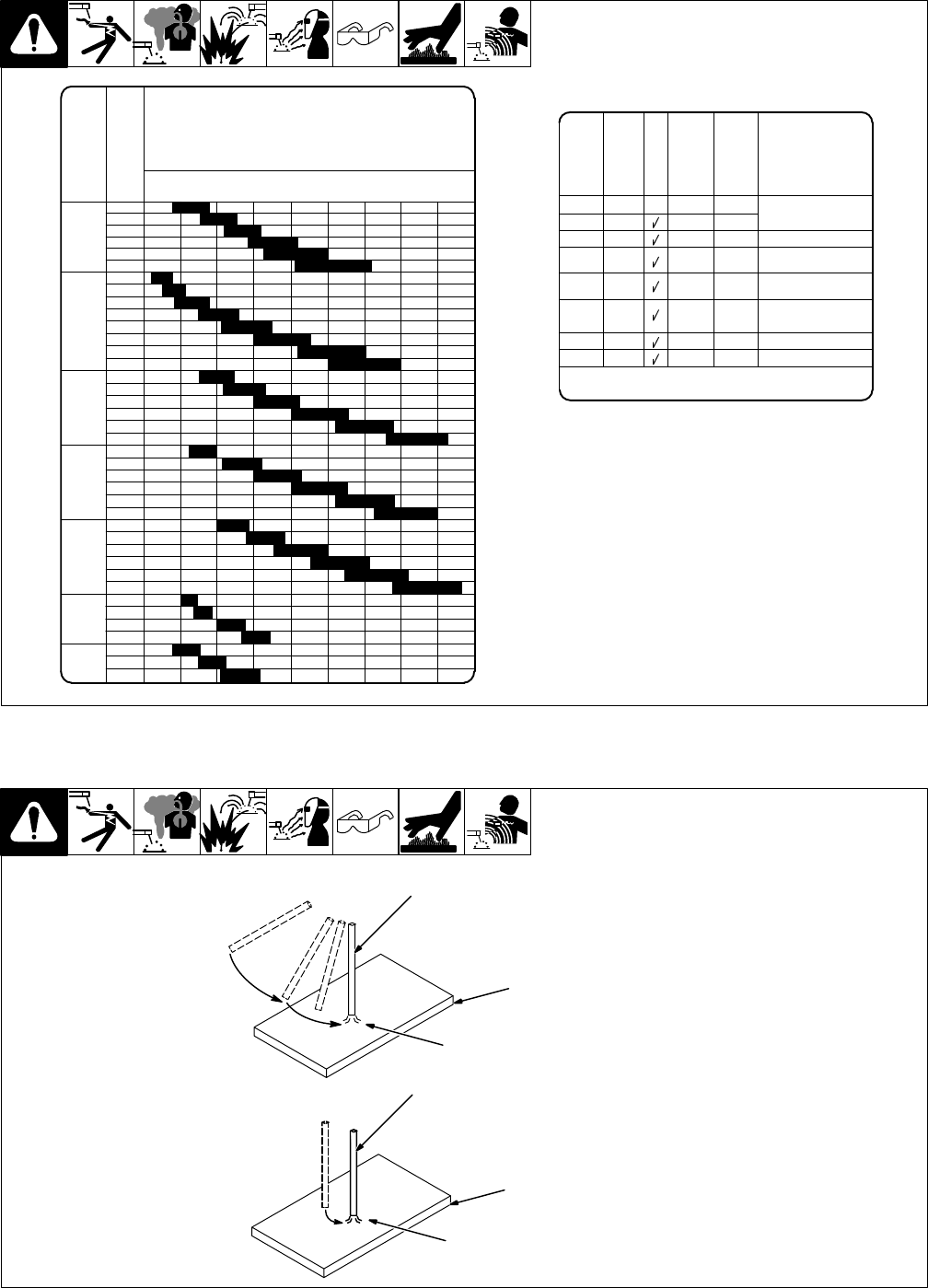

13-3. Striking an Arc

S-0049 / S-0050

1 Electrode

2 Workpiece

3 Arc

Scratch Technique

Drag electrode across workpiece

like striking a match; lift electrode

slightly after touching work. If arc

goes out, electrode was lifted too

high. If electrode sticks to work-

piece, use a quick twist to free it.

Tapping Technique

Bring electrode straight down to

workpiece; then lift slightly to start

arc. If arc goes out, electrode was

lifted too high. If electrode sticks to

workpiece, use a quick twist to free

it.

1

2

3

1

3

2