TM-944 Page 18 Handler 135 / 175

Return To Table Of Contents

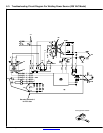

1 Circuit Breaker CB1

Protects unit from an over-current

condition by opening primary power

line.

2 Power Switch S1

Turns unit and fan motor FM on and

off.

3 Fan Motor FM And

Transformer

Controlled by power switch S1. Fan

cools internal components, and

transformer supplies control

voltage to PC1.

4 Thermostat TP1

If unit overheats, TP1 opens

stopping all weld output.

5 Gun Trigger Receptacle RC3

Connects gun trigger circuit to

welding power source.

6 Control Board PC1

Controls weld output by connecting

primary power to main transformer

T1 through a board-mounted

contactor that is activated by

pressing the gun trigger. PC1 also

regulates wire feed motor speed

with a motor control circuit. Speed

is set by feedback from Wire Feed

Speed Control R1.

7 Gas Valve GS1

Controls shielding gas flow.

Pressing gun trigger opens valve.

8 Wire Speed Control R1

Controls wire feed motor speed by

providing a reference voltage to

motor control circuit on PC1.

9 Range Switch S2

Allows selection of weld output

voltage.

10 Main Transformer T1

Supplies power to weld output

circuit.

11 Main Rectifier SR1

Changes the ac output from T1 to

full-wave rectified dc output.

12 Output Capacitor C1

Smooths dc weld voltage from main

rectifier SR1.

13 Stabilizer L1

Smooths dc weld current from main

rectifier SR1.

14 Polarity Changeover Block

Terminals allow changing between

DCEP and DCEN processes.

15 Wire Drive Motor

Feeds wire at a speed set by R1.

Pressing gun trigger activates wire

drive motor.

SECTION 5 − THEORY OF OPERATION

2

34

7

Single-Phase

Line Input

Power

1

Circuit

Breaker CB1

5

Power Switch

S1

Gas Valve

GS1

8

Wire Speed

Control R1

Line

L1

Neutral Line

(115 VAC Model)

Fan Motor FM

And Transformer

Thermostat

TP1

Gun Trigger

Receptacle RC3

Control Board

PC1

6

Line L2

(230 VAC Models)